Flexible and economical fabrication for modernisation projects

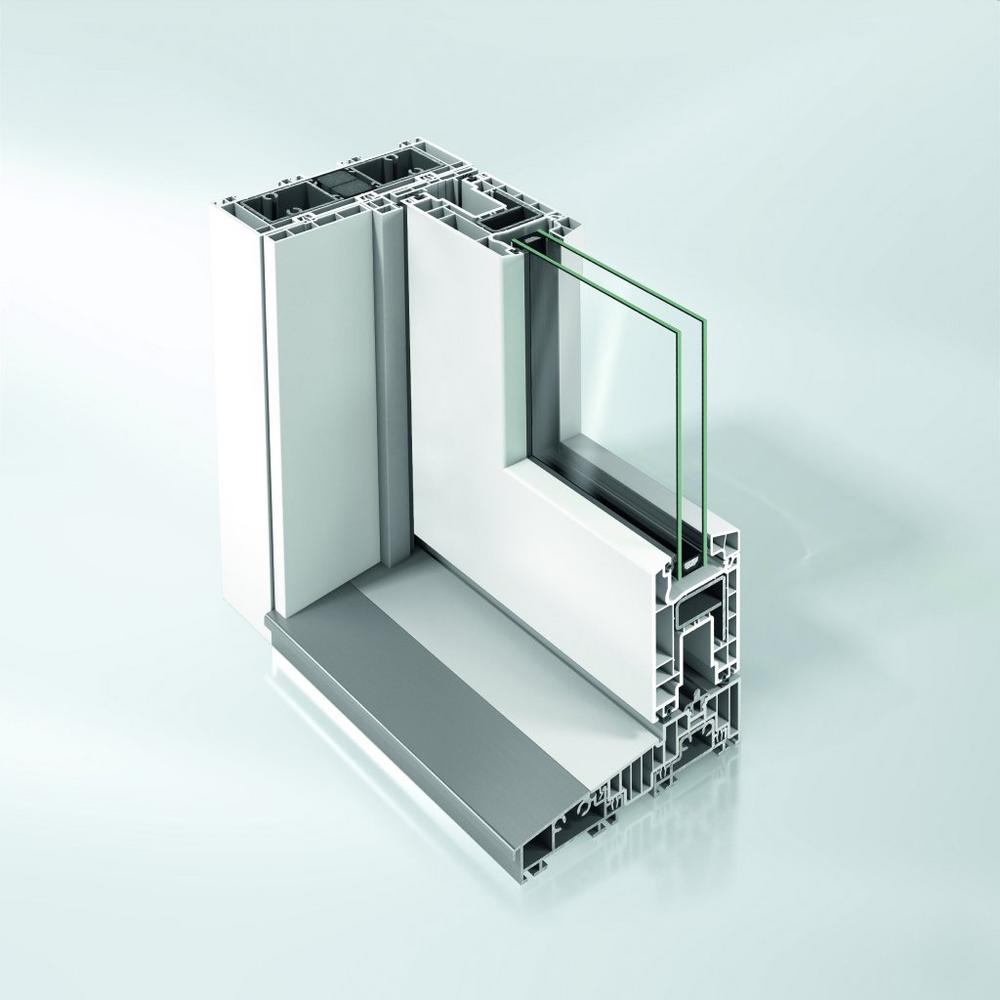

With two, three or four vents, an intermediate or continuous threshold, and double or triple glazing. The newest generation of Schüco EasySlide presents a variety of individual configurations and, compared to the previous version, it offers improvements in the key areas of thermal insulation and security. In addition, many of the details in the lift-and-slide door such as gaskets, corner areas and geometric elements have been further developed, improving the durability of the system even more. The Schüco EasySlide – New Generation now achieves an average Uf value of 1.47 W/(m2K) in the standard design version and can be implemented with burglar resistance up to RC2. The optimised thermal insulation improves the CO2 impact of the building, which can also be reduced by using bio-attributed PVC. With bio-attributed PVC, the raw material crude oil is replaced by tall oil, which is a secondary product of paper production. This is a renewable, non-fossil raw material from pine trees that does not compete with the food chain. In the PVC manufacturing process, compared to primary PVC from the same producer, up to 90 percent of CO2 can be saved. The process is RSB and ISCC PLUS certified, which means that the raw material can be traced along the entire supply chain from the paper producer to the production facility in Weißenfels, which is verified annually by means of an external certification process. The use of bio-attributed PVC also means that the certification requirements for quality level 4 of the German Sustainable Building Council (DGNB) can be met.

For renovation projects

Thanks to the 70 mm profile basic depth of the vents and a frame trim basic depth of 167 mm, the Schüco EasySlide – New Generation is ideal for use in renovation projects. The vent frames are supplied with pre-fabricated, machine-rolled premium gaskets, whereby the maximum thickness of the glazing is 40 mm as standard. This can be increased to 42 mm by replacing the gasket. The lift-and-slide units are sealed on two levels on the inside and outside, which leads to better thermal insulation and excellent joint sealing and weathertightness. The drainage of the profile and the vapour pressure equalisation are concealed so as not to detract from the appearance of the lift-and-slide door. With the Schüco UnlimitedFinish choice of colours and the option to use aluminium cover caps from the Schüco TopAlu series, the new Schüco EasySlide generation also blends perfectly into the appearance of almost any existing building.

Schüco EasySlide was developed based on the 70 mm Schüco CT 70 system platform and it is fully compatible with this system. Thanks to the use of identical parts, an overall limited variety of components and quick installation using four screw ports, the lift-and-slide door can be fabricated cost-effectively and efficiently. The lift-and-slide roller carrier is installed without additional machining around the fittings groove of the lift-and-slide vent frame. In addition to saving time, this has an advantage in that the reinforcing chamber of the vent frame remains completely closed and the same steel cross sections can be used throughout.

Schüco – System solutions for windows, doors and façades

Based in Bielefeld, the Schüco Group develops and sells system solutions made of aluminium, steel and PVC-U for the building envelope. The product portfolio includes window, door, façade, ventilation, security and sun shading systems, as well as intelligent networked solutions for residential and commercial projects. Schüco also provides consultancy and digital solutions for all phases of a building project – from the initial idea through to design, fabrication and installation, as well as after sales with maintenance and servicing. Fabrication machinery and customer-oriented service complement the product portfolio. As one of the leading companies in the construction industry, Schüco is committed to being a pioneer for comprehensive sustainability and to making an active contribution to climate neutrality and the circular economy within the construction sector through its products and services. Founded in 1951, Schüco is now active in more than 80 countries and achieved a turnover of 2.11 billion euros in 2023 with 6750 employees.

For more information, visit www.schueco.com

SCHÜCO International KG

Karolinenstraße 1-15

33609 Bielefeld

Telefon: +49 (521) 78-30

Telefax: +49 (521) 7834-51

http://www.schueco.de

Presse- und Öffentlichkeitsarbeit

Telefon: +49 (521) 783-1155

E-Mail: jbanze@schueco.com

![]()