Practical know-how and knowledge for stable and cost-efficient cleaning processes

The demands placed on the implementation of cleaning processes have changed enormously in recent years. Increasingly stringent requirements for particulate and/or filmic cleanliness must be met. At the same time, the demands on the cost-effectiveness, energy and resource efficiency of cleaning processes are increasing. On the one hand, these changes require employees in the component cleaning production area to have in-depth knowledge of the basic principles and influencing factors in component cleaning. On the other hand, extensive know-how about how the cleaning system works is required for optimum operation, maintenance, and servicing.

Basics and technical system training in a package

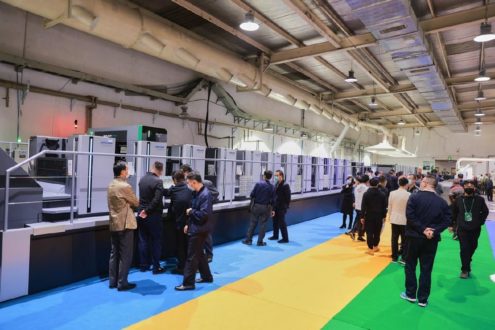

Ecoclean supports users of industrial cleaning technology in these tasks with two-day seminars. The events are divided into a theoretical and practical part with basic training and technical system training respectively. In the basic training presentations, participants are made aware of the factors influencing parts cleaning along the production chain as well as the feasibility and possibilities. In addition, the knowledge required to correctly assess cleanliness requirements is imparted.

On the second day, the practical part takes place in the technical center. Here, standard systems for solvent and water-based cleaning are used as examples to show which adjustments can be made to make optimum use of the system and its performance spectrum.

The basic training courses are held in German at Ecoclean’s Filderstadt site and are aimed at cleaning system operators and employees from the service and maintenance departments. It is also possible to book a one-day course, for example just the basic training or the system training. Dates and the full content can be found on the website under the Academy menu item (https://ecoclean-group.net/…). In addition, the basic training courses can be customized and held at the plant operator’s premises in English or the respective national language.

Process analyses – the holistic, customer-specific approach

It is not uncommon for individual tasks to present companies with challenges in the field of parts cleaning. These include, for example, the fact that specified cleanliness specifications cannot be achieved or can only be achieved with an extremely high level of effort, the need to optimize existing cleaning programs, issues relating to workpiece handling or demands for greater cost-effectiveness or sustainability in cleaning processes. In these cases, a process analysis of all aspects of component cleaning is recommended. The focus here is not just on the cleaning system, but on the entire process chain. All upstream and downstream steps that have an influence on the cleaning result are analyzed on site by two experienced experts and the results are documented in a detailed written report.

Webinars – knowledge and solutions for various tasks

The company’s webinars are an effective and quick way of acquiring expertise and solutions for various tasks in industrial parts cleaning. This year’s interactive online events will be held in German and English and will focus on the following topics:

- Basics of filtration

- Overview of existing measurement technology

- Basics of water treatment

The interactive design of the one-hour webinars allows participants to communicate directly with the speaker and ask questions. The dates and further information can be found on the company’s website under News, Fairs and Events (https://ecoclean-group.net/…).

Contact: Ecoclean GmbH, Academy Filderstadt, 70794 Filderstadt, Germany, Phone +49 711 7006-402,akademy.filderstadt@ecoclean-group.net , www.ecoclean-group.net

The SBS Ecoclean Group develops, produces and sells future-oriented plants, systems and services for industrial component cleaning and surface treatment as well as customized automation solutions. Another business area is the development and series production of efficient alkaline electrolysis systems for the decentralized production of green hydrogen. Innovation is driven by the two competence centers based in Germany, which support the global Group companies with technical expertise, research and pioneering developments. The cleaning solutions, which are world leaders, help companies from a wide range of industries such as mechanical engineering, the semiconductor supply industry, precision optics, medical technology, the automotive and supplier industry, micro and precision engineering, aerospace and fastening technology around the globe to produce efficiently and sustainably with high quality. Ecoclean’s success is based on innovation, cutting-edge technology, sustainability, customer proximity, diversity and respect. The group of companies combines the Ecoclean, UCM and Mhitraa brands. It has eleven production sites in Germany and eight other countries worldwide and employs around 900 people.

Ecoclean GmbH

Mühlenstraße 12

70794 Filderstadt

Telefon: +49 (711) 7006-0

Telefax: +49 711 7006-148

http://www.ecoclean-group.net

Journalistin (DJV) und Texterin

Telefon: +49 (711) 854085

E-Mail: Doris.Schulz@PresseTextSchulz.De

![]()