Conticon boosts copper rod production for the wire and cable industry with a new, state-of-the-art SMS group CONTIROD® line in North America

- Capacity expansion of up to 320 thousand tons of ETP copper rod per year

- Reductions of 55 percent for electrical energy consumption and 30 percent for natural gas

Conticon, a joint venture between Grupo Condumex and Xignux, a manufacturer of electrolytic tough pitch (ETP) copper rod, has commissioned SMS group to expand production capabilities at its plant in Celaya-Villagrán, Mexico, by installing a new CONTIROD®* CR3700 line. This strategic investment in the combined CONTIROD®* casting and rolling process addresses the growing demand for high-quality copper rod for the automotive and telecommunications industries in the region. The new line boosts the capacity of the existing SMS group-supplied CONTIROD®* plant, originally installed in 1984. The current CONTIROD®* line has an annual capacity of approx. 230,000 tons. With an additional 320,000 tons from the new line, the total theoretical capacity is approximately 550,000 tons per year. The project is expected to be completed by the fourth quarter of 2026, with a record delivery time of only 14 months.

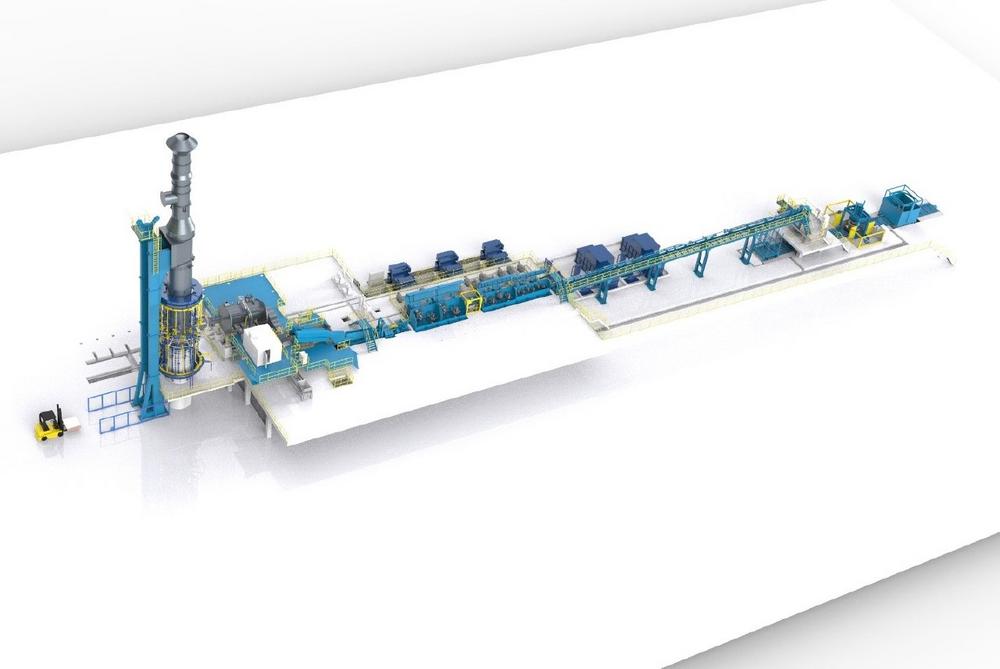

SMS is providing Condumex, Inc with a complete CONTIROD®* line, encompassing both process and electrical equipment to enhance production at the Conticon facility. The new line covers every stage of production, including the charging device, furnace plant, casting machine, rolling plant, and cooling line, as well as the coil forming and handling systems. This comprehensive solution not only increases productivity thanks to its ease of maintenance and operation but also enhances process control and operator safety. The new CONTIROD®* CR3700 line has a capacity of 48 tons per hour. The increased production capacity will enable Condumex to better serve its own group, investment partners, and the export market, effectively addressing the increasing demand for copper wire rod.

The new line offers sustainability benefits, including reductions of 55 percent for electrical energy consumption and 30 percent for natural gas. These efficiencies are achieved through advanced design and process integration and optimized thermal heat utilization, thus minimizing energy waste and enhancing the system’s overall efficiency. The technology package also features process control systems that ensure precise operation, further contributing to energy savings.

SMS and Grupo Condumex share a long-standing relationship, dating back to the installation of the first line in 1984. Over the years, SMS has provided spare parts and implemented upgrades, ensuring the plant’s continued operation and efficiency. The new line is also equipped with SMS-Metrics, a digitalization tool designed for real-time recording, storage, and evaluation of machine data, thereby improving operational efficiency. This latest collaboration consolidates their partnership, highlighting SMS’s dedication to delivering innovative solutions that drive customer success.

*CONTIROD® is a registered trademark of Aurubis Belgium.

SMS group is renowned worldwide for its future-oriented technologies and outstanding service for the metals industry. The company applies its 150 years of experience and its digital know-how to provide the industry continuously with innovative products and processes – even beyond its core business – and generates worldwide sales of around 3.4 billion euros. SMS is the right partner for challenging projects and supports its customers throughout the lifecycle of their plants, enabling profitable and resource-efficient value creation chains. Paving the way for a carbon-neutral and sustainable metals industry is the company’s stated goal. As a global player with German roots, SMS takes responsibility for more than 14,000 employees.

SMS group GmbH

Am SMS Campus 1

41069 Mönchengladbach

Telefon: +49 2161 350-4449

http://www.sms-group.com

Corporate Communications

E-Mail: thilo.sagermann@sms-group.com

![]()