One battery pack per minute: More than 100 KUKA robots in use at FAW-Volkswagen in southern China

The production facility known as the "MEB Smart Factory" was built specifically for the production of the all-electric MEB platform. MEB stands for Modular E-Drive System. For the Volkswagen Group, it is a reference factory for electric vehicles and a flagship for the global automotive industry around automation, smart production and digitalization. The level of automation at the MEB factory is up to 82 percent.

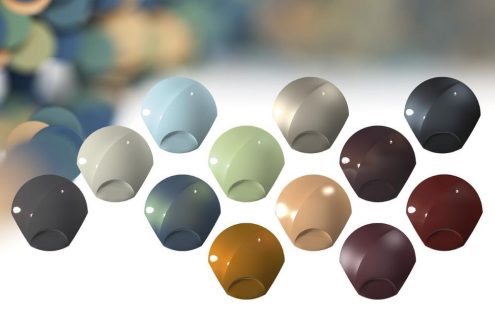

In the factory, welding lines for battery trays are lined up with battery packaging lines. In addition, there are testing devices and logistics. Robots from KUKA weld and glue on the automated welding line for battery cases. They are also used in the packaging of the battery packs. There, robots from the KR QUANTEC, KR FORTEC and KR titan families work together to fully automate the packaging process.

The FAW-Volkswagen branch in Foshan was established in December 2011. Since then, it has been an important part of the FAW Group’s development strategy in South China. In addition to four large production facilities for stamping, welding, painting and final as-sembly, the state-of-the-art MEB Smart Factory was also built here, where FAW-Volkswagen manufactures the core components of electric vehicles.

KUKA is a global automation corporation with sales of around 4 billion euro and around 15,000 employees. The company is headquartered in Augsburg, Germany. As one of the world’s leading suppliers of intelligent automation solutions, KUKA offers customers everything they need from a single source. From robots and cells to fully automated systems and their connectivity in markets such as automotive with a focus on e-mobility & battery, electronics, metal & plastic, consumer goods, e-commerce, retail and healthcare.

KUKA Aktiengesellschaft

Zugspitzstr. 140

86165 Augsburg

Telefon: +49 (821) 797-50

Telefax: +49 (821) 797-5252

http://www.kuka.com

Spokesperson Technology

Telefon: +49 (821) 797-3795

![]()