Aerotech brings movement to the automation process

"The motto of this year’s SPS, "Bringing Automation to Life", is something that I would like to make a little more precise for Aerotech: "Bringing Automation to Motion", says Simon Smith, looking forward to the Nuremberg trade fair. The European Director at Aerotech has good reason to do so, because his topics fit perfectly into the trade fair concept, from control components to automation.

Aerotech has been strengthening its commitment to automation for years and is also positioning itself as a system supplier for high-quality motion control and positioning systems as well as complete automation solutions for the SPS. For over 50 years, the company has offered a wide range of components such as motors, drives, controlers and positioning tables, the majority of which are manufactured in-house. These components are used in a wide range of applications, from electronics manufacturing to medical technology and additive manufacturing.

But Aerotech goes a step further by developing integrated systems that provide near-turnkey solutions for automated processes. These systems include not only the precision motion control components manufactured in-house, including the control platform, but also comprehensive automation integration for part handling, process instrumentation, safety and custom software.

Simon Smith specifies: "As a manufacturer of automation systems, we support manufacturing companies in optimally automating their processes with our precision motion components." Aerotech has developed its motion control technology into the Automation1 motion control platform. This platform can control almost any peripheral device, from linear motion to handling robots to measuring systems. Simon Smith emphasises the flexibility of the motion control platform: "Users can use Automation1 to support their automation process beyond pure motion control. If the process changes and new peripheral components are added, they can be easily integrated into Automation1 without having to purchase new control software. We will be happy to demonstrate how this works to trade visitors at the SPS."

Automation1 with more and more functions

The latest version 2.5 of the Automation1 motion control platform comes with a wealth of new features that significantly improve research, development and industrial automation. Simon Smith comments: "With these additional functions and the user-friendly interface, we are once again demonstrating our expertise as a leading provider of precision motion controls for the most diverse automation solutions."

Galvo scanner calibration is now easier. Users can change calibration and power correction files for galvo laser scanners without resetting the control. Support for higher derivative feedforward control has been improved and laser scan head drives now automatically interpolate feedrate.

Gantry and encoder functions have also been enhanced. There is a new wizard for homing gantries, and users can output quadrature or clock and direction signals from a specific encoder port. A checklist module makes Gantrys setup easier, and Gantry configuration has been optimised.

Another interesting option is the integrated camera module in the MachineApp from Automation1. This allows users to monitor the entire associated automation process live, in addition to motion control. And so that not every user can see into the production via camera, specific MachineApps can be adapted directly in the control platform via an extended HMI interface (Human Machine Interface) and access can be restricted based on user rights or group membership.

Motion system unrestrictedly configurable

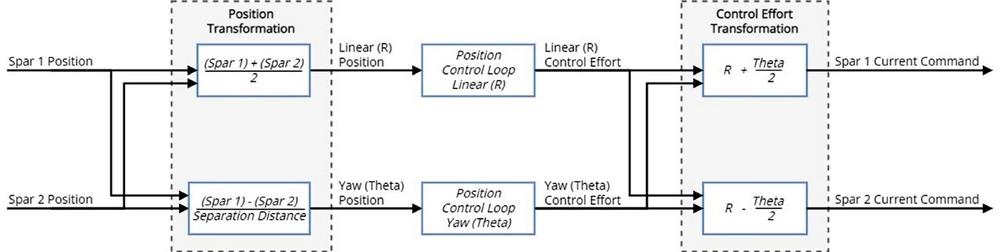

The gantry system shown on the stand consists of two linear actuators with a flexible joint on each axis connected to a plate as a bridge. This demonstrates our gantry configuration capability by allowing the actuators to rotate the entire gantry bridge in differential mode. The system is controlled with Aerotech’s Automation1 controller. "We use our new gantry control with Automation1 to demonstrate how decoupling control of the axes is made possible," explains Simon Smith. "In doing so, the decoupling method performs a coordinate transformation and converts the two physical linear axes into a logical linear axis (R) and a logical rotary axis (Theta). The position of the logical linear axis (R) is thus simply the average of the two physical actuator positions. The logical rotational position (theta) is the difference between the two actuator positions divided by the distance between the two actuators." In an H-bridge gantry, the logical rotational axis results in a yaw movement of the gantry. Decoupling control is also referred to as yaw control. The position control loops act on the logical linear axis (R) and the logical yaw axis (theta) and not on the physical axes. (See the following illustration)

The trade fair demo shows the high flexibility of the Automation1 to control the Theta rotary axis, which can be used for small alignments of the bridge and thus contributes to the flexibility of the gantry system.

Simon Smith adds: "We will also present the auxiliary functions of Automation1 that allow the user to set up the control very easily and quickly." One example of these auxiliary functions, he says, is the setup of the homing routine, where the home position can be automatically set to the centre of the travel range and the system calculates this automatically after moving from limit to limit. This saves the user a lot of time when installing and setting up the motion solution.

Headquartered in Pittsburgh, USA, Aerotech Inc. is an employee-owned, medium-sized company. Founded in 1970 by Stephen J. Botos, Aerotech develops and produces the world’s most powerful motion control and positioning systems for customers in industry, science and research. In the spirit of a family business, the owners continue to place great value on open and trusting dealings with customers, business partners and employees. In Germany, the medium-sized company is represented by its own subsidiary, Aerotech GmbH, based in Fürth, Franconia. In addition to sales and service activities, the customer-specific assembly of positioning systems for the European market also takes place in Fürth. The innovative and high-precision motion solutions meet all the critical requirements needed for today’s demanding applications. They are used wherever high throughput is required – including in medical technology and life science, semiconductor and flat screen manufacturing, photonics, automotive, data storage, laser processing, aerospace, electronics manufacturing and in inspection and testing through to assembly.

With advanced analysis and diagnostic capabilities, Aerotech provides world-class technical support and service. When a standard product is not suitable for a particular application, the manufacturer is able to supply specialised motion components and systems based on its many years of expertise and experience. Manufacturing capabilities for custom applications are complemented by experience in supplying systems for vacuum and clean room applications.

Aerotech has full-service offices in Germany (Fürth), the UK (Ramsdell), China (Shanghai City) and Taiwan (Taipei City). Aerotech currently employs around 500 people worldwide. https://uk.aerotech.com

Aerotech GmbH

Gustav-Weißkopf-Str. 18

90768 Fürth

Telefon: +49 (911) 967937-0

Telefax: +49 (911) 967937-20

http://de.aerotech.com

PRX Agentur für Public Relations GmbH

E-Mail: ralf.haassengier@pr-x.de

Telefon: +49 (911) 967937-18

E-Mail: ufischer@aerotech.com

![]()