Efficiency made easy

Interested people have the opportunity to purchase blind tickets until December 31, 2023. After that, the event can be booked at the official price. Interested companies as exhibitors during the conference are also warmly welcome.

Registration for the conference: kimw.shop

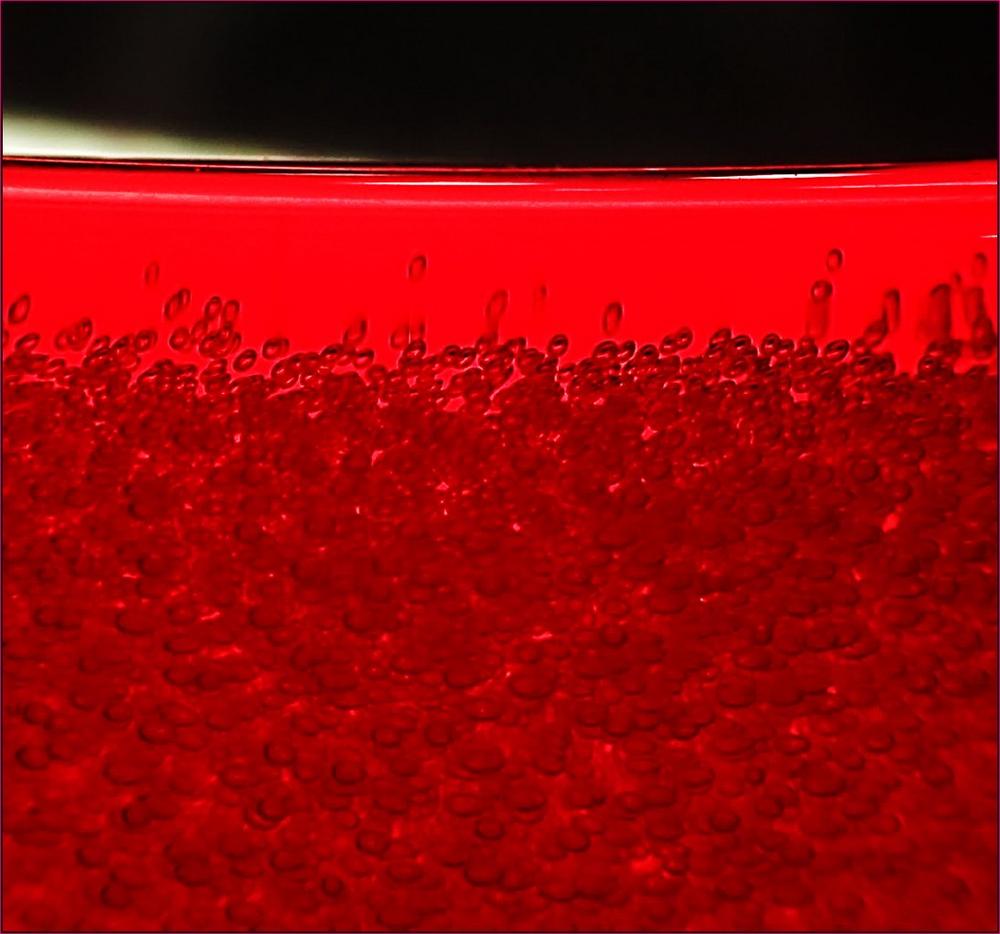

Although it has been known for decades, thermoplastic foam injection moulding FIM with its many advantages have not become fully established but is experiencing a new upswing on resource savings and the need to increase efficiency. It is an advanced manufacturing technology that is used in various industries for different reasons. Weight saving is probably the first catchword that comes in mind with TSG. But instead of simply meaning "less material", the idea can be taken further: More parts can be produced with the available material!

Often, components designed for solid injection moulding can already be foamed and achieve a certain material/weight saving with almost unchanged mechanical properties. However, the full potential is only exploited when the component and process are designed with foaming in mind: The reduction in melt viscosity associated with foaming enables thinner wall thicknesses, for example. Some plastics also allow the melt and/or mould wall temperature to be reduced. These are factors that have a positive effect on the cycle time.

Another major advantage of foaming is that the gas pressure comes from the inside – out in the solidifying melt, which means that the holding pressure otherwise required to compensate for volume shrinkage can be nearly eliminated. This results in further options on the process side that set TSG apart from solid injection moulding: You have the choice of reducing the clamping force of the machine for the same number of parts (energy savings, less stress on injection mould) or increasing the number of cavities (increased productivity). If foaming is planned as a production process from the beginning, it may even be possible to switch to a smaller injection moulding machine.

Cost-wise, a correctly designed foamed part, can be made thinner and any ribbing and other mass accumulations do not lead to sink marks or vacuum voids. The inherent gas pressure in the melt and the elimination of holding pressure mean that components shrink more uniform, thus reducing or even eliminating warpage completely. The result is a more precise part in a shorter cycle time.

If very high weight reductions are required, decompression moulding can be used. The component is made thin(-ner) and before the melt has solidified, the mould is opened in a defined manner. The result is a component with the weight of the thin moulded part but the mechanical behaviour of a thicker geometry. Weight reductions more than 20 and up to 60 percent are common with this technology.

Usually foamed plastic parts have a streaky surface, so the process is often not considered for visible parts. Developments in recent years have shown that this does not have to be the case. On the tool and process side, as well as on the material side, there are solutions for an attractive matt or even high gloss surface.

Would you like to find out more about the foaming conference, foaming or present your company at the accompanying exhibition in the technical centre of the Kunststoff-Institut? Get in touch with us!

Kunststoff-Institut Lüdenscheid

Karolinenstraße 8

58507 Lüdenscheid

Telefon: +49 (2351) 10641-91

Telefax: +49 (2351) 10641-90

http://www.kunststoff-institut.de

Verwaltung Bereich Trägergesellschaft|Marketing

Telefon: +49 (2351) 1064-116

Fax: +49 (2351) 1064-190

E-Mail: premke@kunststoff-institut.de

![]()