Dürr, GROB, and Manz present concept factory for battery production at the Battery Show Europe

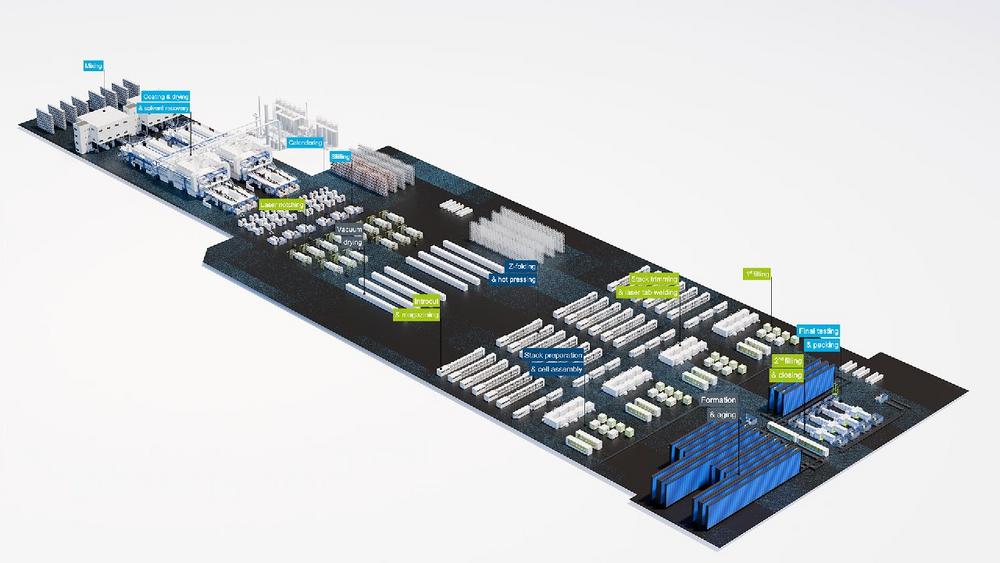

Dürr, GROB, and Manz possess most of the necessary machinery and plant technology to cover the entire process chain from electrode production to cell assembly and from module to pack assembly. Since the partnership began, they’ve focused on developing a concept factory for battery production. In six defined workstreams, particular emphasis was placed on achieving above-average process efficiency during the planning phase.

The goal: production with high overall system efficiency

Both technical and digital interfaces between the three partners are crucial to development. Dürr’s subsidiary iTAC, an expert in process digitalisation, contributes its MES/MOM solution, enabling end-to-end visibility of all battery production steps. This includes control and planning of the entire production process, as well as analysis and traceability. The result is high overall system efficiency and lower operating costs, primarily achieved through reduced energy consumption and a smaller overall plant footprint.

Battery production plant from a single source

The first joint customer project, a system for electrode production and battery cell assembly, is already underway. The single-source approach saves the customers from complex project management, as processing interfaces have been streamlined. Dürr, GROB, and Manz offer smooth implementation following proven project management standards and have an extensive supplier network at their disposal.

As part of the Battery Show Europe 2024 conference program, Dr. Hannes Schmüser (Member of the Board of Dürr Systems AG), German Wankmiller (CEO of GROB Group), and Martin Drasch (CEO of Manz AG) will discuss scaling European battery production – quickly, reliably, and cooperatively. Developing a competitive battery industry in Europe requires more than just political incentives and guidelines. Quality and cost requirements, along with ecological goals, are equally crucial. Full integration of machinery and equipment manufacturers‘ expertise in engineering and project management is essential to ensure competitiveness for cost, quality, and speed.

Visit Dürr, GROB, and Manz from June 18 to 20, 2024, at the Battery Show in Stuttgart in Hall 10, Stand H40. We look forward to welcoming you!

For almost 100 years, GROB has been a globally operating family business in the development and manufacture of systems and machine tools. Its customers include the most renowned automobile manufacturers, their suppliers and companies from a wide range of industries. With production plants in Mindelheim (Germany), Bluffton, Ohio (USA), São Paulo (Brazil), Dalian (China), Pianezza (Italy) and Bangalore (India) as well as worldwide service and sales branches, GROB has an international presence. With 8,800 employees worldwide, the GROB Group generates an output volume of 1.8 billion euros (FY 23/24).

The portfolio ranges from universal machining centers to highly complex production systems with in-house automation, manual assembly stations and fully automated assembly lines. GROB’s product range also includes production systems for electric motors and assembly systems for battery and fuel cell technology. The company also realizes its own solutions for the conventional machining of turbine housings and the machining of structural and chassis components. GROB-NET4Industry, the software developed in-house for the digitalization and networking of production processes, enables production processes to be displayed digitally and transparently.

GROB-WERKE GmbH & Co. KG

Industriestr. 4

87719 Mindelheim

Telefon: +49 (8261) 996-0

Telefax: +49 (8261) 996-268

http://www.grob.de

Telefon: +49 (8261) 996-6546

E-Mail: Anna-Lena.Rehder@grob.de

![]()