How “space heritage” can make space missions like FORUM (ESA) and DRAGONFLY (NASA) more efficient

Only the best will be in space – this is not only true for astronauts but also for all parts of a space mission, including laser systems and laser diodes that are utilized. In order to find which person or which component is the best, there is one thing that is done extensively for everything that has to do with space: Testing.

For laser diodes, this means that all products have to undergo specific tests before they become “space qualifiable” or “space qualified”. Once they have been successfully on a mission, they have “space heritage” that brings along various advantages for future space usages.

Generally saying, three levels of qualification can be identified for laser diodes:

- Industry Level: Built on extensive experience in high-reliability industrial applications

- Space Qualifiable: Includes a specialized bill of materials (BOM), customized processes (when applicable), documentation and additional quality gates

- Space Qualified: Typically, the result of a project with mission-specific requirements, leveraging space-proven materials and processes as mentioned in 2. but followed by successful lot acceptance and qualification tests conducted by Quality Management.

Based on the level of fulfillment of no. 2 and 3, space heritage can be used as a methodology that reduces qualification efforts for processes and components that have successfully been in space before and are built under the same conditions.

The advantage of space heritage was a real game changer for TOPTICA EAGLEYARD’s 1064 nm DFB, which was requested by ESA and NASA for the FORUM (ESA) and Dragonfly (NASA) missions.

ESA’s FORUM mission*, launching in 2027, will pioneer the measurement of Earth’s far-infrared radiation from space, enhancing climate models and policy decisions with advanced instruments and international collaboration. Only a year later, NASA’s Dragonfly mission** is planned to be launched. It will explore Saturn’s moon Titan using a drone-like rotorcraft to study its organic-rich surface, atmosphere, and potential for prebiotic chemistry, offering insights into early Earth-like conditions.

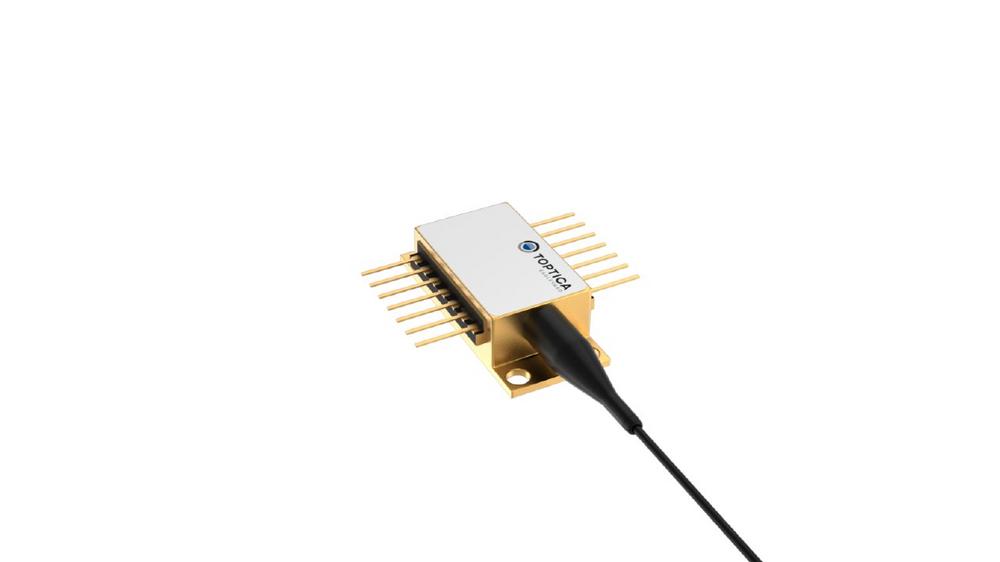

EAGLEYARD’s 1064 nm DFB is a fiber-coupled single-frequency laser diode that produces a very stable, narrow linewidth – a very important factor and a prerequisite before further testing could even be considered.

On the FORUM mission, the 1064 nm DFB in butterfly platform will be operated as a seed-laser for interferometry so that distances can be measured on the mission. As the requested DFB needed to have less power (only 5 mW) than the standard product offered by TOPTICA EAGLEYARD, a two-stage micro-isolator was integrated – with the challenge not to cause additional qualification effort by this design change to keep the space heritage level untouched. For NASA`s Dragonfly mission, same chips and building blocks are used as for the FORUM mission: the fiber-coupled DFB 1064 nm in hermetically sealed butterfly platform only differs in power, stages of integrated micro-isolators and operational mode. Used as a seed-laser, this DFB will be pulsed in contrast to EAGLEYARD’s standard product that is operated in continuous wave so that the thermal load is lower and the laser diode can be operated at a higher power level that is required for the LIDAR application used on the mission.

In addition to the high performance EAGLEYARD’s DFB 1064 nm laser diode offers, space missions require high reliability even under extreme conditions. Therefore, multiple tests become necessary and that’s the time when space heritage can be exploited.

Fortunately, TOPTICA EAGLEYARD’s DFB 1064 nm has space heritage from missions such as GAIA (ESA), MERLIN (DLR/CNES) and C.A.T.S. (NASA). This allows components that have already been tested and qualified for space missions to be reused without having to go through the entire Test Readiness Level (TLR) verification again – a real game changer for the new missions the DFB 1064 nm will be involved in. Space heritage can save significant time and money, and components can avoid redundant testing if they are manufactured under the same conditions as the original. The TRL verification is divided into two major parts: Evaluation and Qualification as shown in image 02.

The evaluation of the technology according to ESCC 23201 comprises destructive tests, endurance tests, step-stress tests, constructional analysis, irradiation, environmental and electro-optical tests in different test groups as shown in image 2. Due to the space heritage of the DFB 1064 nm these were completely unnecessary for the FORUM mission – resulting in cost and time savings of 100% for the evaluation tests and 50% of total project costs.

In the qualification phase, LOT acceptance tests take place according to ESCC 23202. These extensive tests include aging tests of 10,000 hours and screening tests in these subgroups: mechanical, environmental, endurance, assembly capability, electrostatic discharge sensitivity, radiation and thermal vacuum (as shown in image 2). Once these tests are passed, one assumes that the actual flight parts that go on the mission behave in the exact same way and are therefore approved for space usage.

Summing up, it becomes very obvious which advantages space heritage can bring along and how this makes the integration of laser diodes a lot more efficient. With a strong history and constant focus on space, TOPTICA EAGLEYARD is strengthening its expertise in this area making it a very reliable supplier for future missions that can benefit from significant time and cost reductions.

Learn more about space qualification in this article: Easier space qualification for laser diodes | Laser Focus World

About the missions:

*The ESA FORUM (Far-infrared Outgoing Radiation Understanding and Monitoring) mission, launching in 2027, will be the first to measure Earth’s far-infrared radiation from space, accounting for over half of the planet’s outgoing energy. Equipped with a Fourier transform spectrometer and an imager, FORUM will provide crucial data on greenhouse gases and water vapor, enhancing climate models and supporting policy decisions. It complements the MetOp Second Generation program, delivering comprehensive thermal radiation measurements. Led by Airbus UK, with contributions from Germany (OHB) and Italy (Leonardo), FORUM will launch aboard a Vega-C rocket from Kourou, French Guiana, marking a breakthrough in climate monitoring. Learn more about the mission here: https://www.esa.int/Applications/Observing_the_Earth/FutureEO/FORUM

**NASA’s Dragonfly mission aims to explore Saturn’s moon Titan, a world rich in organic compounds, to investigate prebiotic chemical processes that could resemble those on early Earth. Launching in July 2028, Dragonfly will arrive at Titan in 2034 and use its eight-rotor, drone-like design to fly to dozens of sites, analyzing Titan’s surface chemistry, atmosphere, and potential for life-related molecules. The mission’s scientific goals include understanding Titan’s complex carbon-rich environment and its potential as an analog for early Earth. Managed by the Johns Hopkins Applied Physics Laboratory, Dragonfly is NASA’s first rotorcraft mission on another planet, involving international collaboration with agencies like CNES, DLR, and JAXA under NASA’s New Frontiers Program. Learn more about the mission here: https://science.nasa.gov/mission/dragonfly/

TOPTICA EAGLEYARD is based in Berlin, Germany, and is a leading supplier of high-power laser diodes with wavelengths ranging from 630 nm to 1120 nm. TOPTICA EAGLEYARD’s products are used around the globe and combine maximum performance and unparalleled service life with excellent beam quality, making them especially suitable for industrial, medical, scientific, and space applications. TOPTICA EAGLEYARD came about in 2002 as a spin-off from the renowned Ferdinand-Braun-Institut (FBH). Today, it plays a leading role in its sector thanks to its exceptional GaAs-based laser diode portfolio. By properly and professionally applying its expertise, experience and know-how, it has developed research results into marketable products that are sold worldwide, either directly or through partners. TOPTICA EAGLEYARD has been part of the TOPTICA Group since 2013. You can find more at www.toptica-eagleyard.com.

eagleyard Photonics GmbH

Rudower Chaussee 29

12489 Berlin

Telefon: +49 (30) 63924520

Telefax: +49 (30) 63924529

http://www.toptica-eagleyard.com

Marketing

Telefon: +49 (30) 6392-4561

E-Mail: stephanie.hannibal@toptica-eagleyard.com

![]()