Kardemir commissions SMS group to supply a five-strand combi-continuous caster to expand its production range and output

- Production capacity will be 1.2 million tons annually

- Increased flexibility and efficiency, allowing the manufacture of billets, beam blanks, and blooms

- The new facility will be operational by the end of 2025

Kardemir Karabük Demir Çelik Sanayi ve Ticaret A.Ş has placed an order for a five-strand combi-continuous caster for its integrated steel plant with SMS Concast, a company of SMS group, to upgrade production capabilities at its Karabük site in Türkiye. The facility is scheduled to go into service at the end of 2025, marking a production milestone for Kardemir and reinforcing its position as one of the leaders in the Turkish steel sector.

The new five-strand combi-continuous caster enables the production of a wide range of formats and steel grades, offering quick changeovers for enhanced efficiency. It is intended to increase Kardemir’s production capabilities and enable it to react to changing industry demands. The casting plant is designed to manufacture three square billet sizes, one bloom size, and one beam blank section size, with an overall annual output of 1.2 million tons.

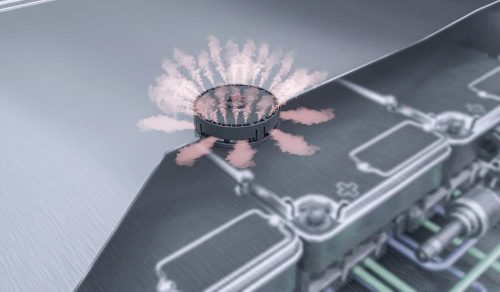

The new continuous casting plant, featuring a 10.25-meter radius, is also capable of producing a wide range of steel grades, including construction and high-carbon rail grades. SMS technology will add several features that increase plant availability and product quality. The large, long-life tundish and CONFLOW stopper mechanism ensure stable and accurate steel levels in the mold, which are crucial for maintaining high product quality and reliable casting operations. The use of CONVEX mold tubes and CONSTIR electromagnetic stirrers enhances both the casting speed and internal product quality.

The CONDRIVE oscillation drive provides for precise online settings of the casting mold, enabling independent control of the amplitude, frequency, and oscillation profile.

The scope of supply includes advanced level 1 and level 2 automation systems with technical solutions for controlling and optimizing the supplied machine’s processes. The level 2 systems, featuring fault-tolerant hardware for continuous operation, ensure consistent quality, production reliability, and independence from the pulpit operator’s subjectivity, and assist with product certification to increase the plant’s availability.

Kardemir and SMS look back on a long partnership lasting over 25 years. With the five-strand combi-continuous caster, the customer has once again chosen SMS to continue their successful partnership. Future cooperation in the field of SMS’s digital solutions, including AI-driven systems for optimizing caster operation and boosting production efficiency, is also part of the project.

With the five-strand combi-continuous caster, the customer has again underscored the mutual commitment to innovation and excellence, paving the way for enhanced technological advancements and operational success.

The management team at Kardemir expressed their enthusiasm for the new collaboration: “Our longstanding and trustful partnership with SMS group has enabled us to work effectively towards realizing this project. We are confident of achieving a swift and seamless project execution, setting a new standard in the Turkish steel industry.”

SMS group is renowned worldwide for its future-oriented technologies and outstanding service for the metals industry. The company applies its 150 years of experience and its digital know-how to provide the industry continuously with innovative products and processes – even beyond its core business – and generates worldwide sales of around 3.4 billion euros. SMS is the right partner for challenging projects and supports its customers throughout the lifecycle of their plants, enabling profitable and resource-efficient value creation chains. Paving the way for a carbon-neutral and sustainable metals industry is the company’s stated goal. As a global player with German roots, SMS takes responsibility for more than 14,000 employees.

SMS group GmbH

Eduard-Schloemann-Straße 4

40237 Düsseldorf

Telefon: +49 (211) 881-0

Telefax: +49 (211) 881-4902

http://www.sms-group.com

Fachpresse

Telefon: +49 (211) 881-4449

Fax: +49 (211) 881-774449

E-Mail: thilo.sagermann@sms-group.com

![]()