For manual and fully automated handling

Intralogistics is looking towards fully automated warehouses with shuttles, SRMs and autonomous robots. Nevertheless, conventional handling still has a right to exist. The racking and storage specialist Galler from Kulmbach (Upper Franconia) will be demonstrating at Logimat that it is at home in both the manual and automated worlds. – Hall 1, Stand 1F61.

The Omega pallet racking with its striking profile cross-section, reminiscent of the Greek omega, provides a literally stable basis for Galler’s storage and shelving technology. Galler uses it to build multi- and single-user racking and is one of the few suppliers that even has a hot-dip galvanized multi-user solution with roof and wall for outdoor placement in its catalog. Galler also continues to offer its customers drive-in racks, whose designers and installers have made themselves scarce.

XXL roller conveyor for heavy load carriers

Also, in the Galler range: push-back racks, order picking flow racks and mobile racks for pallets. A strong “junior” in the range are the XXL roller conveyor systems for large load carriers. They can withstand a load of up to two tons per square meter, with each individual roller carrying 400 kilograms. Even load carriers with feet and runners, which often cause other conveyor systems to stop working, move smoothly over the XXL roller conveyor. One exhibit will be on display at Logimat.

Network for complete solutions

As part of a group of companies, Galler offers a comprehensive product range that also includes storage platforms, cantilever and shelving racks. “By combining several specialist areas, we are positioning ourselves as a full-service provider in the field of storage and shelving technology,” says Galler Sales Manager Jörg Kilz. ” That’s why our Logimat stand is always about comprehensive intralogistics concepts.”

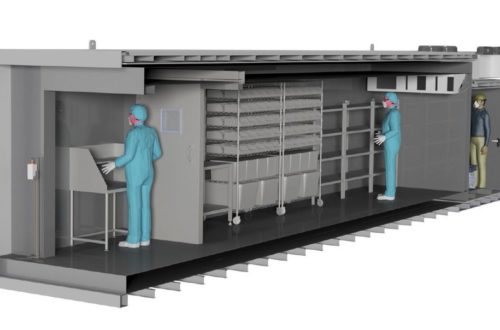

High-bay warehouse with RGB and shuttle

This leads to automation solutions, such as high-bay warehouses with automatic storage and retrieval machines (RGB) or multi-level shuttle systems. The most important components of these Galler products are also profiled, welded and surface-treated in Kulmbach.

Height: Galler plays in the “upper league”

The high-bay storage silos from the Upper Franconian shelving specialists are not new. But they are likely to be a hot topic at the Logimat stand because Galler has decided to build significantly higher than 22 meters again. The first project inquiries are already in the pipeline. “We are now also playing in the top league again in terms of height,” explains Kilz:” Our high-bay storage silos are in demand for handling large quantities of individual products with high turnover rates. Because the rack construction supports the roof and walls of a warehouse, there is no need to construct separate halls and buildings.” – You could also say that high-bay storage silos are extremely economical. And that always goes down well in the logistics world.

Galler Lager- und Regaltechnik GmbH manufactures flexible shelving systems for a wide range of requirements – from manual storage in workshops to fully automated high-bay warehouses.

Founded in 1917 by Wenzel Galler and integrated into Hölscher Holding in 2004, the company has played a decisive role in shaping shelving technology for over 100 years. Today, Galler is increasingly present in the DACH region with its network of experienced sales staff but is also able to realize projects worldwide.

Galler employs a total of 100 people at its Kulmbach site. All beams and uprights for Galler shelving systems are “Made in Kulmbach”.

Galler Lager- und Regaltechnik GmbH

Robert Galler Str. 1

95326 Kulmbach

Telefon: +49 (9221) 700-0

Telefax: +49 (9221) 700-149

http://www.galler.de

Telefon: +49 (9221) 700-0

E-Mail: sarah.schmitz@galler.de

![]()