Certification in Spite of Coronavirus Pandemic: Quality Management in the Automotive Industry

IATF 16949 Relies on Extensions and Monitoring

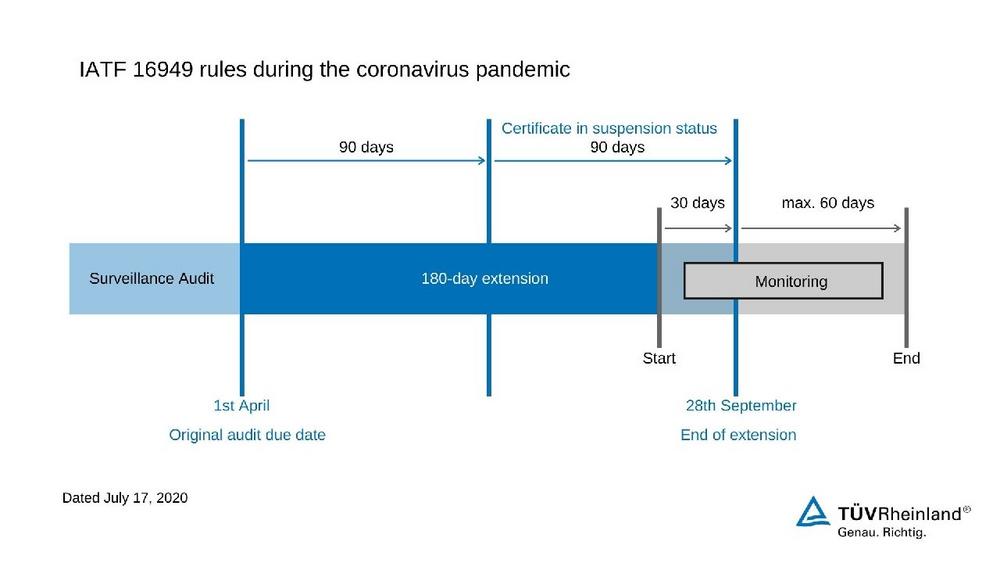

Due to the coronavirus pandemic, for some ISO standards, remote audits can be conducted instead of on-site audits under certain circumstances. “On the other hand, the IATF 16949 standard is increasingly prescribing extended deadlines and risk assessments based on monitoring,” explains Daniela Huch, Automotive Industry Quality Management Expert at TÜV Rheinland. This gives companies extra time if they need to arrange an annual surveillance audit during their certification cycle. This means that, due to the coronavirus pandemic, a company whose surveillance audit would have been due on or before April 1 will be granted two 90-day extensions. During the second 90-day extension, the certificate is suspended but still valid.

Monitoring Requirements and Procedure

Within the total extension period of 180 days, companies can arrange for a regular surveillance audit to be performed by their inspection companies or instead make a monitoring request. Monitoring is a form of risk analysis with fixed criteria, and is performed remotely rather than on-site. However, this analysis is tied to certain conditions: The company must currently produce automotive parts or products for customers, and its business must be affected by the COVID-19 pandemic such that it would not be possible to conduct an on-site audit. Monitoring can take place no earlier than 30 days prior to the end of the 180-day extension period and no later than 60 days after this period. It takes at least one day to complete, and more time may be requested depending on the size of the company. Monitoring is now being used as an alternative to the regular annual surveillance audit. Companies having to arrange a recertification audit after a period of three years are not eligible for monitoring. They will be granted a six-month extension instead. This only applies to companies where an on-site audit would not be possible due to COVID-19.

“TÜV Rheinland is ready to conduct monitoring. But so far, many automotive companies are opting to have their surveillance audits completed by the due date or, where possible, within the first 90-day extension period but no later than within the second 90-day extension period. They are still not taking advantage of monitoring at the moment,” Daniela Huch has observed. TÜV Rheinland has developed special guidelines on how to conduct corporate audits while taking maximum safety precautions to ensure that it is able to perform surveillance audits, including on-site inspections, smoothly and safely. Protecting customers and employees is the top priority. “But close communication between TÜV Rheinland and the company being audited is just as important. Good organization and clear arrangements also help to minimize risk,” sums up Daniela Huch.

Sicherheit und Qualität in fast allen Wirtschafts- und Lebensbereichen: Dafür steht TÜV Rheinland. Mit mehr als 21.400 Mitarbeiterinnen und Mitarbeitern und einem Jahresumsatz von 2,1 Milliarden Euro zählt das vor rund 150 Jahren gegründete Unternehmen zu den weltweit führenden Prüfdienstleistern. Die hoch qualifizierten Expertinnen und Experten von TÜV Rheinland prüfen rund um den Globus technische Anlagen und Produkte, begleiten Innnovationen in Technik und Wirtschaft, trainieren Menschen in zahlreichen Berufen und zertifizieren Managementsysteme nach internationalen Standards. Damit sorgen die unabhängigen Fachleute für Vertrauen entlang globaler Warenströme und Wertschöpfungsketten. Seit 2006 ist TÜV Rheinland Mitglied im Global Compact der Vereinten Nationen für mehr Nachhaltigkeit und gegen Korruption. Website: www.tuv.com

TÜV Rheinland

Am Grauen Stein

51105 Köln

Telefon: +49 (221) 806-2148

Telefax: +49 (221) 806-1567

http://www.tuv.com

Pressesprecherin Systeme

Telefon: +49 (221) 806-4465

E-Mail: Antje.Golbach@de.tuv.com

![]()