To further accelerate R&D work for novel coronavirus (COVID-19) test reagents, Hamamatsu Photonics has developed a new fluorescence immunochromato reader with both high sensitivity and high reproducibility

This new immunochromato reader (lateral flow reader) does high-sensitivity detection of reagent reactions occurring with antigens such as viruses and hormones or antibodies reacting with viruses, etc. It is a promising tool for streamlining R&D work on immunochromatographic reagents including those for novel coronavirus (COVID-19). We start accepting product orders from domestic and overseas reagent manufacturers on October 1st (Thu), 2020. We will also be supplying this immunochromato reader as a commercially available OEM (original equipment manufacturer) product that matches the reagents produced by each manufacturer.

<Immunochromatography>

Immunochromatography is a testing method used for determining whether a sample or analyte such as from blood and nasal swabs contains antibodies or antigens.

A sample is dripped onto an immunochromatographic reagent and the color developing on the test line is checked to determine whether antigens or antibodies are present in the sample. At that point, the greater the amount of antigens or antibodies contained in the sample, the darker the color that appears. Although immunochromatography sensitivity is low compared to the PCR (Polymerase Chain Reaction) method, the testing is easy and results can quickly be obtained in about 15 minutes making it ideal for examining myocardial markers, hormones and allergies as well as influenza viruses. Also in recent years, intensive development efforts are underway to find highly sensitive reagents using fluorescent labels.

<Product Overview>

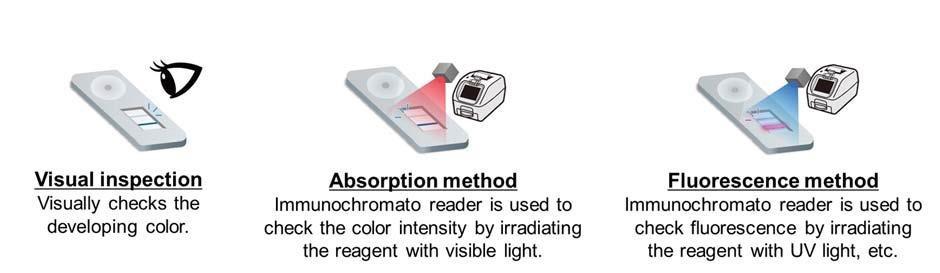

In immunochromatography, the color intensity is usually checked by visual inspection, which can sometimes be a problem since tiny amounts of antigens and antibodies sometimes make it very difficult to identify the color. However, using our immunochromato reader allows easily determining whether antigens or antibodies are present even when in just tiny amounts. Another benefit is that measurement results are quantified so that more accurate determinations can be made.

Our new immunochromato reader irradiates an immunochromatographic reagent with UV light and detects light (fluorescence) emitted from fluorescent labels that bind to the antigens or antibodies. This ensures measurements with high sensitivity and high reproducibility.

We have already developed and produced two immunochromato reader types. One type uses the absorption method where the color intensity is checked by irradiating visible light onto the reagent. The other type utilizes the fluorescence method having higher measurement sensitivity. We have been shipping these to reagent manufacturers for use in their R&D and quality control applications. Currently, the importance of immunochromatographic screening tests for novel coronavirus is rapidly increasing and R&D work is in progress to discover reagents with even higher test accuracy. There is also a growing demand for fluorescent Immunochromato readers having higher sensitivity in order to streamline R&D tasks and to boost accuracy in diagnosing infectious diseases.

In the measurement using an immunochromato reader, increasing the intensity of light irradiated onto the reagent increases the signal but also poses a problem that the noise is amplified as well.

We have now succeeded in reducing the noise by applying our own signal processing technology developed in-house while also increasing the signal by enhancing the irradiation light intensity and using an amplifier circuit. We also reassessed the components from scratch and optimized the optical design so that measurement sensitivity is boosted 10 times or more compared to that of currently available products. Moreover, the coefficient of variation (CV) which expresses variations in measurement results is held to within 3% by applying data analysis technology we have fostered over the years. This is equivalent to the level of our current products and is the industry’s highest standard of measurement reproducibility.

Using our new high-sensitivity and high-reproducibility immunochromato reader to examine reactions of reagents to antigens or antibodies will prove an ideal way to streamline R&D work on reagents for novel coronavirus and other uses. Our new immunochromato reader is also able to check low intensity fluorescence that have been difficult to detect until now and so will expand the range of reagents that can be quality-controlled. What is more, we provide OEM products for specific reagents to help enhance accuracy when diagnosing infectious diseases at hospitals and clinics.

We will keep pushing forward to create products that can detect light emitted from all types of fluorescent labels and will expand our product lineup to handle many different types of reagents.

<OEM products>

Infectious disease diagnoses made by way of immunochromatography rely on immunochromatographic reagents that react with specific target antigens or antibodies. At reagent manufacturers, R&D work using immunochromato readers is constantly underway to discover reagents that are highly optimized for detecting specific antigens or antibodies. Using a reagent developed by reagent manufacturers and an immunochromato reader specifically customized for that reagent allows making a highly accurate diagnosis of infectious diseases and ensures full maximum reagent performance at hospitals and clinics.

We have been supplying OEM products tailored to match the various reagents produced by manufacturers for infectious disease diagnosis. The technology for our new immunochromato reader is also built into OEM products, so they will increase accuracy when testing for infectious diseases such as novel coronavirus and influenza infections that usually require quick and early diagnosis. We also welcome custom design requests from customers such as for space-saving and smaller device footprints.

<Main product features>

1. Measurement sensitivity boosted more than 10 times higher than current products

We succeeded in reducing the device noise by applying our own advanced signal processing technology while increasing the amount of light signal from fluorescent labesl bound to antigens or antibodies. We accomplished this by enhancing the intensity of light irradiated onto the reagent and by adding an amplifier circuit. We also reassessed the components from scratch and optimized the optical design to successfully boost measurement sensitivity by10 times or more compared to currently available products.

2. Industry’s highest level reproducibility: CV 3%

We have been selling immunochromato readers for R&D and quality control of immunochromatographic reagents since 2003. Thanks to our own in-house data analysis technology fostered over the years, the CV or coefficient of variation is kept within 3% which is the industry’s highest level of measurement reproducibility and equivalent to that of our current products.

Hamamatsu Photonics Deutschland GmbH

Arzberger Str. 10

82211 Herrsching am Ammersee

Telefon: +49 (8152) 375-0

Telefax: +49 (8152) 375-199

http://www.hamamatsu.com

Public Relations

Telefon: +49 (8152) 375-185

Fax: +49 (8152) 375-199

E-Mail: rfritsch@hamamatsu.de

![]()