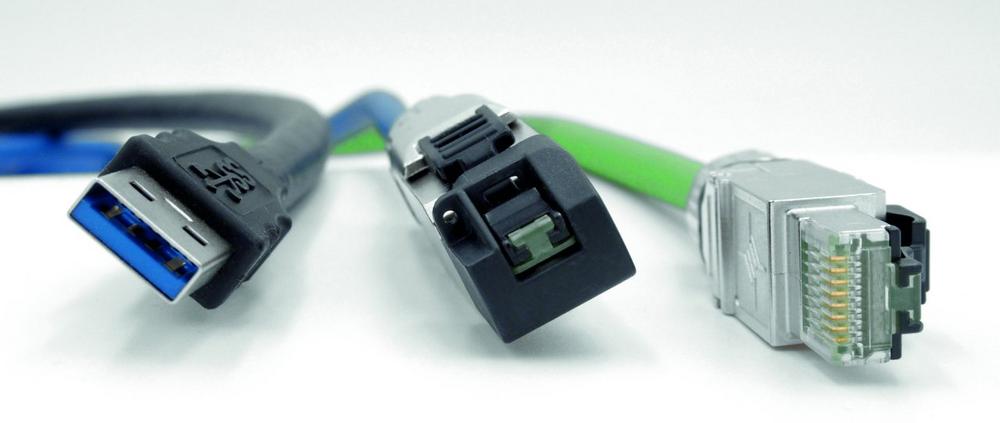

Minimize mismatches due to Signal Integrity Engineering on the „medical-grade“ USB 3.0 cable

When designing USB 3.0 cable there are several challenges to consider for optimum performance and application compatibility. For example, for medical applications USB 3.0 cables should be lightweight, very flexible without memory effect to avoid kinking or craning. In addition, the cable should be autoclavable and flexible enough to be used with hand held devices. In order to ensure these characteristics, the choice of raw materials and manufacturing processes must be precisely coordinated.

High-precision manufacturing processes for cable production

Asymmetries in cable can quickly lead to interferences due to differences in propagation time and signal radiation, while large process tolerances lead to mismatching and reflections. As a consequence, this can lead to transmission losses, distortion of the signal, runtime and data errors and ultimately to reduced image quality.

"The precision of the manufacturing processes and the selection of impedance-relevant materials have a considerable influence on the transmission characteristics", says Marc Gerlatzek, product manager for the medical technology division at SAB Bröckskes GmbH & Co KG. "Through targeted signal integrity engineering and comparison with our documented empirical values from a large number of measurements, we ensure homogeneous transmission values over the entire cable length.

Length-dependent factors such as "voltage drop" or attenuation are limiting factors. Cable cross sections for increased power transmission are just as much a part of the requirement profile as are tolerated outer diameters.

Customer-specific productions possible from 100m

In order to create or customize customer-specific specifications the cable specialist from Viersen rely on close customer contact. Once custom cable solutions are agreed upon cable manufacturers should guarantee exclusive manufacturing to dedicated production lines otherwise knowns as serial production to ensure from prototyping to mass production the manufactured process is controlled with no variances from separate production batches. Custom Cables with production minimums as low as 100 meters can be tested under real time conditions which enhances the experience between customers and SAB specialists therefore addressing improvements and continuous success.

Cable manufacturer – SAB Bröckskes is one of the world’s leading manufacturers of cables and wires, cable assemblies and temperature measurement technology. More than 70 years of experience in cable and wire production and temperature measurement and control technology have turned a one-man business into a company with 500 employees. The strengths lie not only in the production of standard cables and wires, but also in the design of special articles. Every year SAB produces more than 1500 special cables on customer request.

SAB Bröckskes GmbH & Co. KG

Grefrather Str. 204-212b

41749 Viersen

Telefon: +49 (2162) 898-0

Telefax: +49 (2162) 898-101

https://www.sab-kabel.de

Telefon: +49 (2162) 898276

Fax: +49 (2162) 898116

E-Mail: info@sab-broeckskes.de

Telefon: +49 (2162) 898146

E-Mail: adrovic@sab-broeckskes.de

![]()