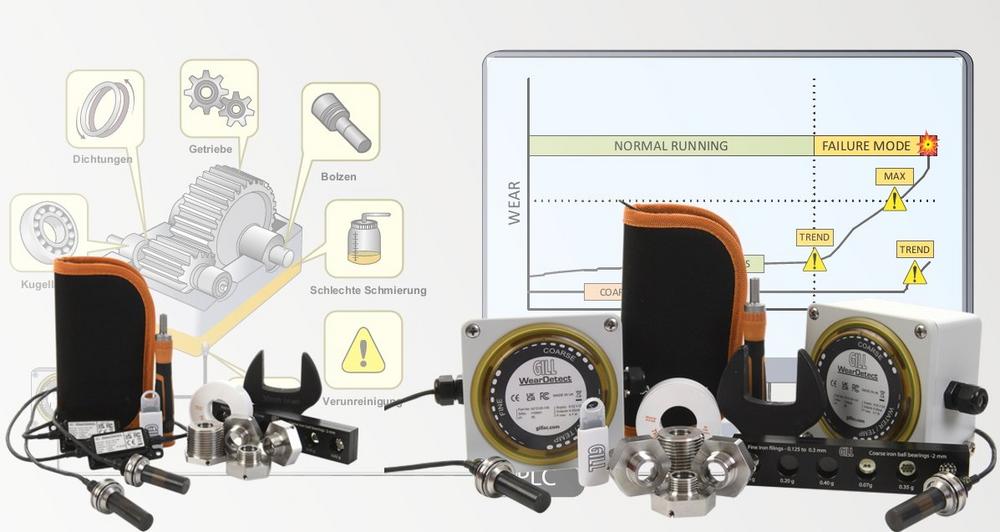

WearDetect: The new starter kit for a fast and easy entry into real-time condition monitoring

The Oil Debris Sensor 4212/4212i attracts and retains the ferrous particles using a strong internal magnet. Not only does it remove the debris from the oil flow but it can differentiate and detect the type of contamination and the quantity. With two output channels for fine (wear) and coarse (failure) particles the sensor is able to continuously indicate the cleanliness of the oil and provide the earliest possible indication of component deterioration.

The oil-debris sensor can recognize a fault much earlier than vibration sensors can and counter measures can be taken much earlier.

Simple to install as a replacement sump plug, it has a high temperature operation and can play a pivotal role in helping to maintain plant and equipment availability and reduce unplanned downtime.

The new 4212 WearDetect starter-kit is perfect for a fast and easy entry into real-time condition monitoring:

It comes in two versions – with two electronic module sensors (4212) or two sensors with industrial display (4212i) – and includes the following components:

• 2 x WearDetect oil debris sensors • 1 x Probe installation kit (ten different thread adaptors and one Crows foot spanner

• 1 x Precision tool kit for installation • 1 x Fine and coarse debris test strip • Access to on-line training video and content

Typical applications are in gearboxes, in motorsport, agriculture industry, wind generators as well as heavy duty applications.

For further information visit our web site: www.sensors.de

For sensor know-how, visit our online sensor compendium www.sensoren.info (in German)

disynet GmbH

Breyeller Str. 2a

41379 Brüggen-Bracht

Telefon: +49 (2157) 8799-0

Telefax: +49 (2157) 8799-22

http://www.sensoren.de

CEO

Telefon: +49 (2157) 8799-21

E-Mail: hh-echobotmedia@disynet.de

![]()