Calculation Software TBK – New Release with Numerous Enhancements for Gearings

The TBK calculation software has been used successfully worldwide for the design of gears, shafts, connections, bearings and other machine elements for more than four decades. With the system extension SystemManager and various interfaces to 3D CAD systems, the TBK software is a powerful tool especially for gear development for both stationary and mobile applications.

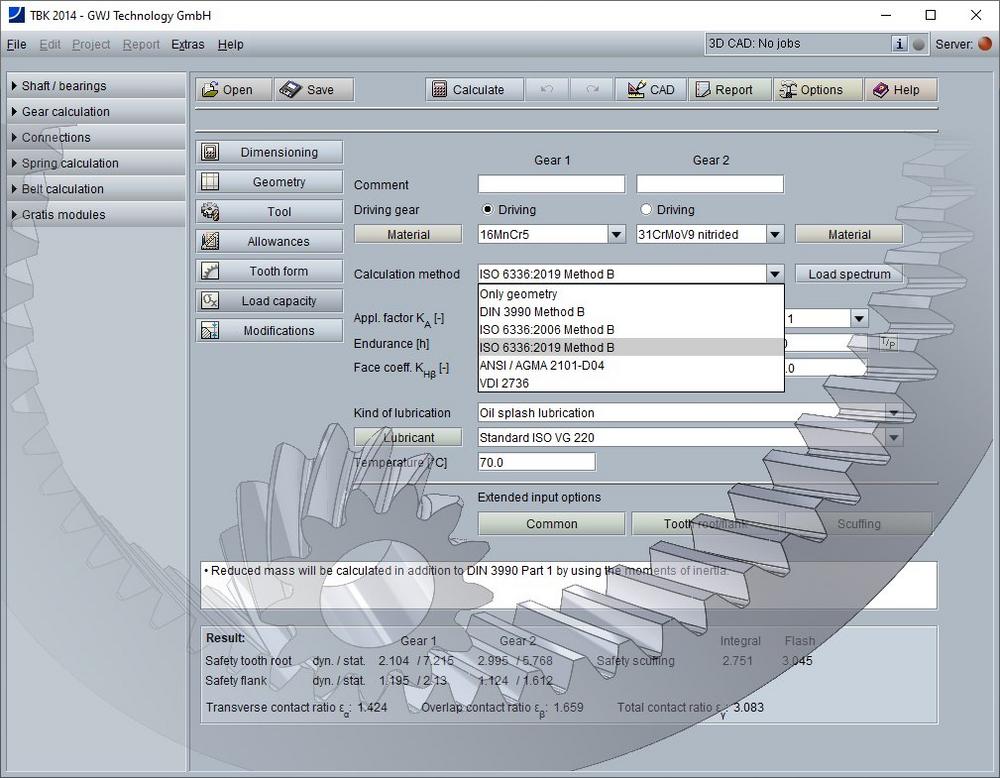

In the latest version, the calculation modules for cylindrical gear pairs, planetary gear stages, three- and four-gear train systems as well as gear racks have been extended to include the latest edition of ISO 6336 (2019-11) for calculating the load capacity as well as VDI 2736 for calculating the load capacity of plastics. These calculation methods are available in parallel to DIN 3990 Method B, ANSI/AGMA 2101-D04 and the previous edition of ISO 6336 (2006-09).

Furthermore, the calculation of master gears according to ANSI/AGMA 2002-C16 has been integrated into the cylindrical gear pair and planetary gear stage modules. This makes it possible to determine test gears or their center distances and measuring radii quickly and easily. Both parallel and crossed axis positions of the test gears are supported. The calculation of test gears for ring gears or internal gears is also possible. In the calculation module for spiral bevel gears, a new function is now available for designing the profile shift coefficients for balanced specific sliding. For straight bevel gears, the "Duplex" bevel shape has been added as a further variant, which is of particular interest for forged bevel gears. Both bevel gear modules now also support calculation with load spectra.

The strength classes for stainless steel screws and other materials for clamped parts and plates have been added to the calculation module for highly stressed bolted joints.

In the current release, 3D output in STEP/IGES format is now also available. In addition to solid models for cylindrical gears, gear racks, involute splines and bevel gears, surface models of the tooth space geometries can also be generated. In addition, further output options for the DXF format and many other new functions have been added.

Visit www.gwj.de for more information or contact GWJ at +49 (0) 5311293990 or send an email to info@gwj.de.

Focusing on mechanical engineering, GWJ Technology stands for high-quality products and professional software development for mechanical engineering to support engineers and designers in their daily work. The GWJ product range of innovative calculation software is wide – from standard software for classical machine elements with 3D CAD integration modules to the determination of whole systems up to a complex special software for 5-axis milling of gears. There are common features that all GWJ solutions share – intuitive design, sleek interface, easy to use and suitable applications for all users from beginner to very advanced. GWJ is constantly working on software enhancements and adding new features to the system in order to keep the applications up-to-date. Professional competence, state-of-the-art technology, a demand for high quality and excellent customer services are the key factors in GWJ´s business philosophy to give the customers the best possible service and advice to obtain new competitive advantages.

GWJ Technology GmbH

Celler Straße 67 – 69

38114 Braunschweig

Telefon: +49 (531) 129399-0

Telefax: +49 (531) 129399-29

http://www.gwj.de

Geschäftsführer

Telefon: +49 (531) 1293990

Fax: +49 (531) 12939929

E-Mail: g.weser@gwj.de

![]()