Faster and more precise: Cross-cutting function in the servo drive

The cross-cutting function is always used in mechanical engineering when defined material lengths must be cut or machined. In metalworking, for example, this can be a pipe cut, or a paper or foil cut in other areas. Printing via stamps, for example, is also an area of use. In addition to its cross-cutting library in the control unit, the drive and automation specialist Baumüller offers a newly developed drive-based solution for these applications. The function is integrated directly in the servo controller and therefore achieves even faster response times and greater precision.

Fast and precise: software in the drive impresses with lean system

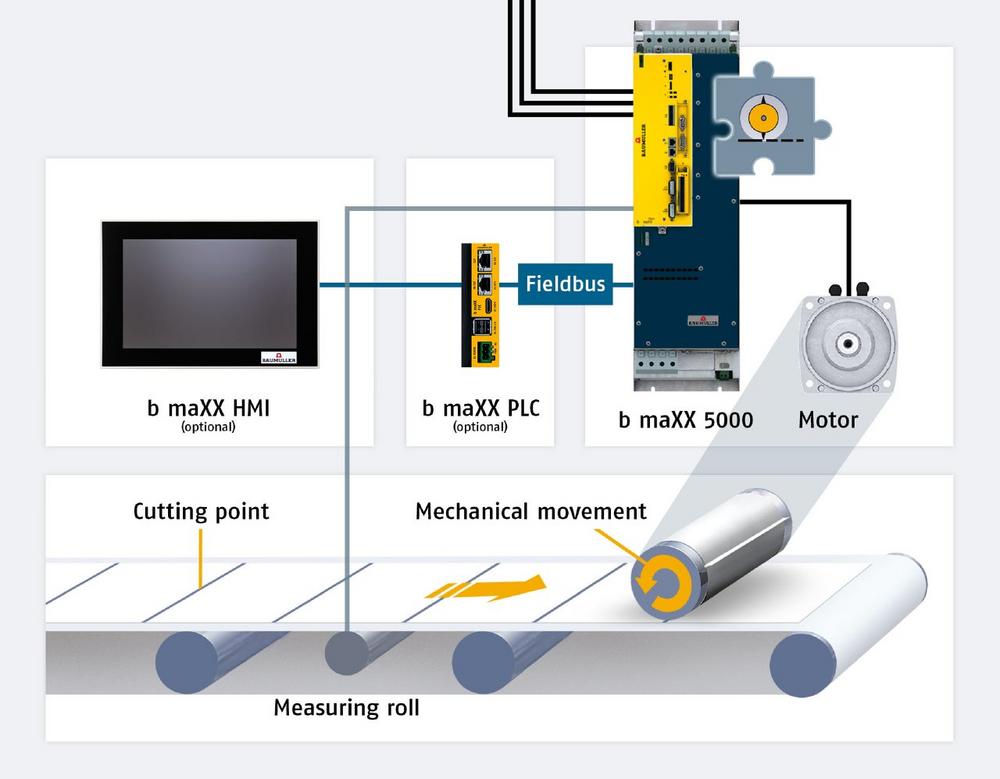

The converters of the Baumüller b maXX 5000 family are equipped with the integrated highperformance control platform b maXX-softdrivePLC. This enables control functions to be loaded directly onto the drive. Programs can therefore run highly synchronized with the controller clock at cycle times up to ≤125 μs. Baumüller has now used this intelligence in the drive in its new cross-cutting solution and lets the function run directly in the servo drive. Once transferred into the drive, this intelligence forms its own, lean system with numerous advantages. Separate control hardware is therefore not necessary for a large number of applications or can be reduced, saving effort and costs.

The control circuit runs in the fast converter cycle, which means higher dynamics and process accuracy. The process quality is also ensured at a slower clock rate of the field bus. Since Baumüller converters provide a large number of fieldbus interfaces, the drive-based solution can be integrated as a subsystem in the higher-level systems with little effort.

If the solution is used as an autonomous subsystem and, for example, diagnosis or parameterization by the user is required, it is also possible to link a separate HMI.

Time advantage: parameterizing instead of programming

No programming knowledge whatsoever is needed for the finished technology solution, the movements merely have to be parameterized. All parameters, e.g. transmission factor, distance from the measuring point or roll circumference are adjustable.

Major advantages in using the Baumüller technology solutions include the non-existent programming work due to simple parameterization, the shorter time to market, and the lower costs. The customer can therefore conveniently fall back on validated and tested technology experience.

Based in Nuremberg, Baumüller is a leading manufacturer of electric automation and drive systems. At production sites in Germany, the Czech Republic, Slovenia and China as well as in over 40 branches worldwide, around 2,000 employees develop and produce intelligent system solutions for machine manufacturing and e-mobility.

In addition, the range of services offered by the Baumüller Group includes engineering, assembly and industrial relocation as well as services, thus covering all aspects of life cycle management.

Baumüller Gruppe

Ostendstraße 80-90

90482 Nürnberg

Telefon: +49 (911) 5432-0

Telefax: +49 (911) 5432-130

http://www.baumueller.com

Marketing Manager

E-Mail: L.Kemnitzer@baumueller.de

Marketing Communications Manager

Telefon: +49 (911) 5432-319

E-Mail: stefanie.lauterbach@baumueller.com

![]()