SILATHERM® enables advanced heat management

- Thermally conductive fillers increase the thermal conductivity of polymers

- Electrical insulating properties of the plastics used are maintained

- Innovative gap filler with SILATHERM® offer high performance

More than just a stopgap

Mineral fillers have long ceased to be cost-effective „gap fillers“! They can be used to modify the properties of modern polymer systems in a targeted manner and to adapt them to special requirements. Acicular and platelet-shaped functional fillers give thermoplastics, thermosets and elastomers outstanding values in the area of mechanical strength and thermal parameters. Recently, however, new requirements have been added to these classic demands. For example, the use of electrical components with high energy density requires efficient dissipation of the heat generated while maintaining the electrical insulation performance of the plastic materials used.

The real gap fillers

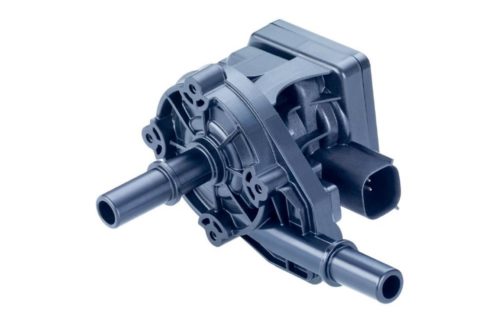

Developers have a choice of thermal management materials at their disposal. Metals are increasingly being replaced by plastics. The traditional air cooling of electronic components is disappearing due to the progressive miniaturisation of assemblies containing a larger number of components with high energy density. These are often replaced by heat sinks in conjunction with heat-conducting surfaces. Here, actual gap fillers are absolutely necessary. As part of a well thought-out thermal management, thermally conductive silicones fill the air gaps within the electronic assemblies. Air, with its low thermal conductivity, can significantly impair heat transfer between the heat sink and the component. Innovative gap fillers containing the thermally conductive SILATHERM® products offer high performance and easy handling, making them a valuable tool in the design of new complex geometries.

Functional fillers increase the thermal conductivity of plastics

Thanks to many years of experience in the preparation and refinement of mineral fillers, the SILATHERM® product series has made it possible to develop new types of fillers that significantly increase the thermal conductivity and mechanical properties of plastics. At the same time, the materials meet the requirement for insulation against electric current. Due to continuous further development, optimised particle size mixtures for higher filling levels are also available. For all products, a significantly better homogenisation can be achieved by surface coating, which is adapted to the customer’s system. This leads to even better mechanics and higher thermal conductivities.

About HPF The Mineral Engineers:

The Quarzwerke division HPF The Mineral Engineers has been developing and selling high performance fillers and additives for polymer systems based on natural and synthetic minerals for years. HPF has its own sales offices in Seoul, South Korea (HPF Minerals Ltd.) and near Milan, Italy (HPF Italia S.r.l.). In 2021, HPF Minerals Tech Ltd. state-of-the art production plant went into operation in Dangjin, South Korea. The high-performance fillers produced there in proven quality will be supplied to the entire Asian region.

The Quarzwerke Group is an independent international family business with nearly 140 years of tradition and a significant market position in the extraction, processing and refining of industrial minerals, mainly from its own deposits. More than 30 production sites have been located in Europe for a long time.

Headquartered in Germany, the company is organised into six divisions. The approximately 3,500 employees in the Quarzwerke Group work on contributing to the success of our customers worldwide.

HPF The Mineral Engineers – A Division of Quarzwerke Group

Augustinusstr. 9D

50226 Frechen

Telefon: +49 (2234) 101-0

Telefax: +49 (2234) 101-480

http://www.hpfminerals.com

Marketingreferentin

Telefon: 02234 101 411

Fax: 02234 101 480

E-Mail: Liesenfeld@hpfminerals.com

![]()