-

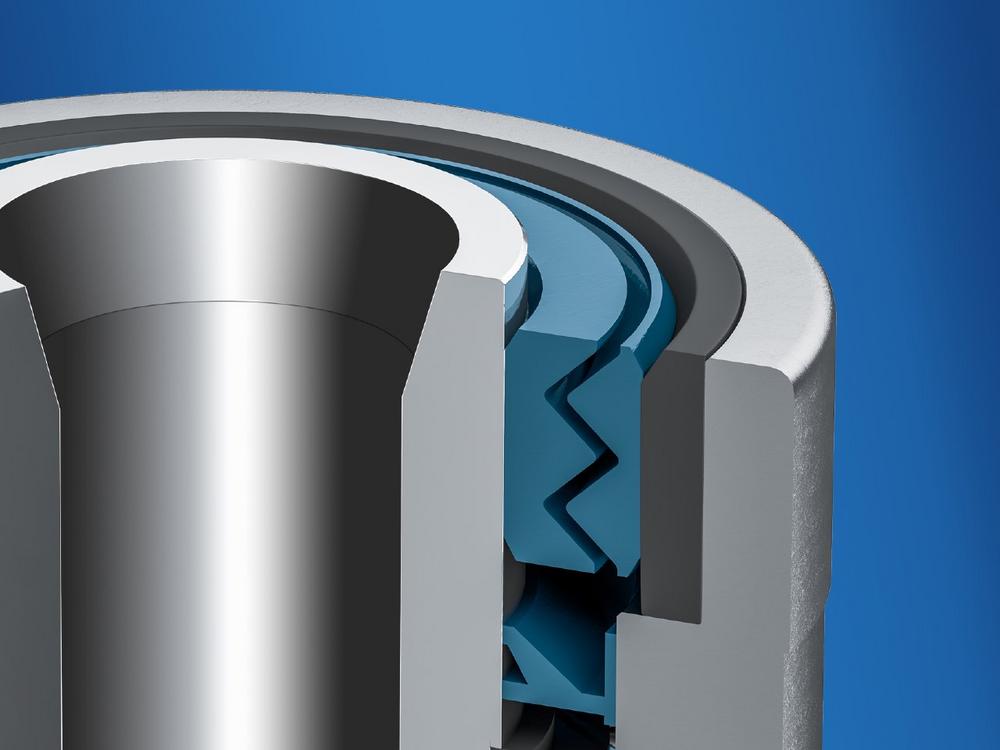

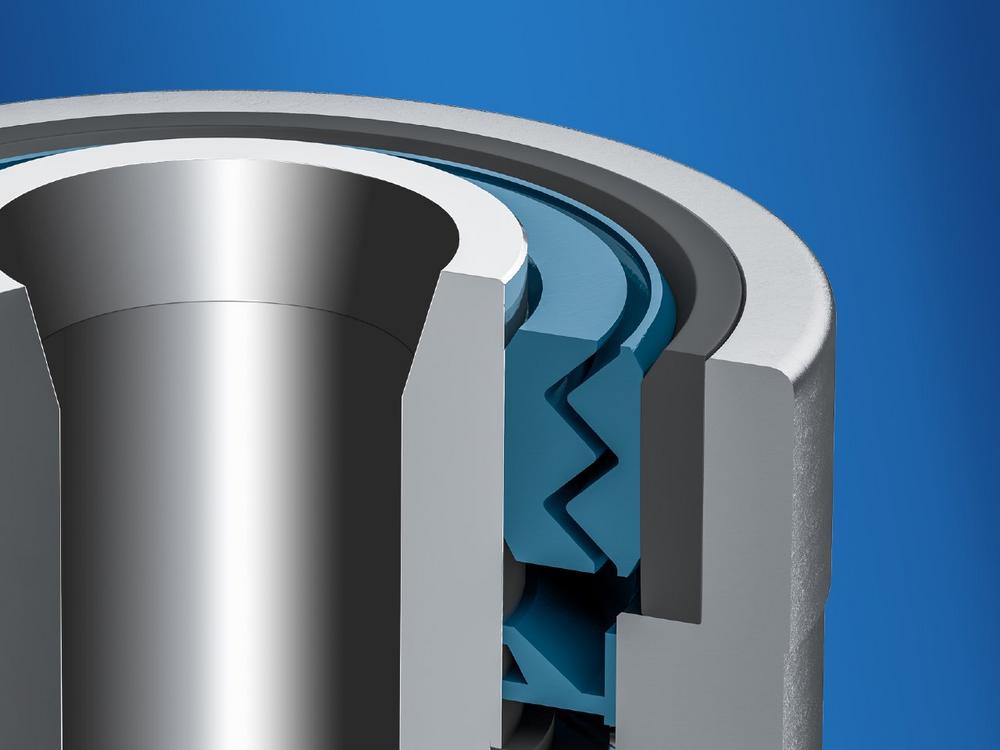

Effective tool change cleverly designed with inductive miniature sensors

In modern processing centers, inductive sensors are the components of choice for monitoring the motor spindle clamping process. Integrated into the spindle, they must be exceptionally small and offer high repeatability to ensure smooth tool changing at all times. Baumer offers a high-performance portfolio of miniature sensors for the intelligent design of effective spindle solutions. This can either involve a classic design with three switching sensors or a smart design with one measurement sensor. Tool change in fully automated processing centers, from removal until the insertion of the new tool in the spindle, takes less than a second. To achieve maximum system effectiveness, this process must function with ultimate reliability.…

-

Effective tool change cleverly designed with inductive miniature sensors

In modern processing centers, inductive sensors are the components of choice for monitoring the motor spindle clamping process. Integrated into the spindle, they must be exceptionally small and offer high repeatability to ensure smooth tool changing at all times. Baumer offers a high-performance portfolio of miniature sensors for the intelligent design of effective spindle solutions. This can either involve a classic design with three switching sensors or a smart design with one measurement sensor. Tool change in fully automated processing centers, from removal until the insertion of the new tool in the spindle, takes less than a second. To achieve maximum system effectiveness, this process must function with ultimate reliability.…

-

Digital and analog interface benefits all at once thanks to Dual Channel

Digital communication opens up many opportunities – but only sensors that reliably deliver precise measured values offer real added value by IO-Link. Well established and appreciated by many users, both pressure sensor PP20H and CombiLyz AFI conductivity sensor excel by outstanding measuring performance and IOLink interface, but now they offer even more interesting features such as simple and fast parameterizationeven during operation. This way, secondary data like different process data output simultaneously or diagnostic data only accessible this way can be communicated from sensor to controller or even retrieved from the sensor memory if required. Further to the digital interface, the sensors also provide one or more conventional analog outputs…

-

An innovation with added value – the PP20H pressure sensor with IO-Link wins the Innovations Showcase Award

The pressure sensor prevailed among the 17 finalists due to its condensate-resistant silicon measuring cell, exceptional precision across the entire temperature range, and IO-Link interface. “An IO-Link interface is the latest trend in the sector and we have incorporated this technology in our PP20H,” says Baschar Al Hammoud, product manager for pressure sensors. However, in true Baumer style, the company did not settle for that without offering its customers extra benefit – in addition to the digital IO-Link interface, the PP20H also offers an additional analog output. Baschar Al Hammoud explains, “With this combination, the PP20H offers users more flexibility than any other pressure sensor.” This way, during commissioning of…

-

Digital and analog interface benefits all at once thanks to Dual Channel

Digital communication opens up many opportunities – but only sensors that reliably deliver precise measured values offer real added value by IO-Link. Well established and appreciated by many users, both pressure sensor PP20H and CombiLyz AFI conductivity sensor excel by outstanding measuring performance and IOLink interface, but now they offer even more interesting features such as simple and fast parameterizationeven during operation. This way, secondary data like different process data output simultaneously or diagnostic data only accessible this way can be communicated from sensor to controller or even retrieved from the sensor memory if required. Further to the digital interface, the sensors also provide one or more conventional analog outputs…

-

HeavyDuty rotary encoders – the high precision heavyweight champions

HeavyDuty rotary encoders from Baumer Hübner are the "original". More than half a century ago, Baumer Hübner developed this type of particularly reliable and robust rotary encoders. Since then they have been used in all situations where the going is tough and where failure is not an option. What distinguishes a HeavyDuty rotary encoder exactly and what options do they offer users? Dockside cranes that unload thousands of tons of shipped goods daily. Conveyor systems that carry thousands of tons of mined ore from mining plants across many kilometers. Elevators that carry thousands of people daily. Automated production lines on which automobiles in various assembly stages are transported. Lifting bridges…

-

Miniature strain sensors measure large forces even in confined spaces

The miniature-format strain sensors DST20 complement the Baumer portfolio by adding a compact and cost-efficient solution for measuring large forces above 10,000 N even in confined spaces. With their dimensions of 28x12x10 mm, the DST20 miniature strain sensors offer space savings that are unmatched by any other screw-on strain sensor on the market. At the same time, their stainless steel housing and a certification for the IP 65 degree of protection make them excellently suited for use in rough production environments and for a large range of applications, such as mechanical and equipment engineering as well as process automation. The DST20 strain sensor can be integrated into a machine with…

-

HeavyDuty rotary encoders – the high precision heavyweight champions

HeavyDuty rotary encoders from Baumer Hübner are the "original". More than half a century ago, Baumer Hübner developed this type of particularly reliable and robust rotary encoders. Since then they have been used in all situations where the going is tough and where failure is not an option. What distinguishes a HeavyDuty rotary encoder exactly and what options do they offer users? Dockside cranes that unload thousands of tons of shipped goods daily. Conveyor systems that carry thousands of tons of mined ore from mining plants across many kilometers. Elevators that carry thousands of people daily. Automated production lines on which automobiles in various assembly stages are transported. Lifting bridges…

-

Arla Foods analyses energy consumption using flow sensors

Dairy cooperative Arla Foods has, for the first time, created transparency over the energy consumed in cottage cheese production at its Falkenberg location. This involves the use of the Baumer Flex-Flow® sensor, which is able to measure the temperature of the medium as well as the flow rate.This cost reductions this could achieve in the future quickly made this a worthwhile investment. At its Falkenberg location, dairy cooperative Arla Foods produces 20 000 tonnes of cottage cheese every year equivalent to 76.9 tons per day. An impressive quantity indeed. Arla Foods satisfies almost the entire cottage cheese demand on the Swedish market and also exports to Finland, Denmark and Greece.…

-

Clever³ – simpler. More reliable. More intelligent

The original puts you one step ahead – point level detection has never been this easy and reliable. Thanks to the new level switch PL20, the CleverLevel series from Baumer now offers more possibilities for detecting point levels. CleverLevel reliably detects every type of medium, whether liquid, pasty, viscous, or solid, and is therefore the solution for a variety of applications for which standard vibrating forks are used today. One of its major advantages is the fact that it does not have to be parameterized to a medium as before but flexibly adapts to the medium at hand. This way, even adhesions such as those that frequently occur with pasty…