-

Improving Steel Level Measurement in Continuous Casting

In the world of continuous casting, the most effective method for gauging steel levels is through radiometric-based mould level measurement. This well-established technology has been in use for over 50 years and has been adopted in over 6,000 systems worldwide. In this discussion, we’ll explore its performance, consistency in results, factors that influence it, how sources are selected, and a recent breakthrough: the ability to measure the thickness of the casting powder layer at the same time. Continuous casting plants play a crucial role in improving the quality of steel and cutting down production costs significantly. This is achieved by saving on investments and workforce expenses, using materials more efficiently,…

-

Measurement solution for the most challenging processes

Berthold Technologies radiometric instruments for non-invasive level and density measurement are used in industries worldwide, including the oil refining and the petrochemical industry. Our measurement solutions, utilizing gamma absorption, assist our customers in achieving highly reliable process control. This ensures safe operations, maximizes efficiency, and ultimately boosts profitability. Berthold is known for cutting-edge technology and high-quality products. We offer an extensive array of industry-standard solutions, while also collaborating closely with our customers and licensors to design customized systems specifically tailored to their unique processes and measuring requirements. New level measurement solution: LB 476 Level+ LB 476 Level+ adds that little extra to radiometric level measurements, which makes it the perfect…

-

Water & solids content for the dairy industry

Water is a characteristic component of dairy products. It determines consistency and influences the taste as well as the quality of the final product. In most countries, the water content of butter is subjected to strict monitoring. According to one regulation, for example, the water content of butter in Europe may not exceed 16 %. With the latest microwave technology, it is possible to monitor the water or solid content during production in real time, which enables early detection of deviations. This makes it possible to maintain consistent quality and cost-efficient production. It also ensures that the dairy products comply with all legal requirements and that the product meets expectations.…

-

Online-Feuchtemessung für Schüttgüter, Pulver und Granulate

Als Hersteller verschiedener Feuchtemesssysteme im Bereich Prozessmesstechnik bieten wir Ihnen die optimale Lösung für Ihre Anwendungen an. Der Feuchtegehalt ist bei vielen industriellen Produktionsprozessen ein wichtiger und entscheidender Qualitätsparameter. Eine genaue Überwachung der Feuchte bei der Produktverladung sichert die Einhaltung von Lieferbestimmungen. Unsere Online-Messung ermöglich ermöglicht eine optimale Prozesssteuerung, mit kosteneffizientem Energieeinsatz bei Brenn- oder Trocknungsprozessen und reduziert den Ausschuss während der Produktion. Die einfachen robusten und zuverlässigen Messsysteme von Berthold arbeiten ohne durch Staub, Temperatur oder Farbe beeinflusst zu werden. Von der Lebensmittelindustrie über Kraftwerke bis hin zur Pharmaindustrie – die Einsatzgebiete unserer Messsysteme sind vielfältig. Das sind die Vorteile der Feuchtemessung von Berthold: Kostenoptimierte Produktion durch Echtzeitmessung Leichte…

-

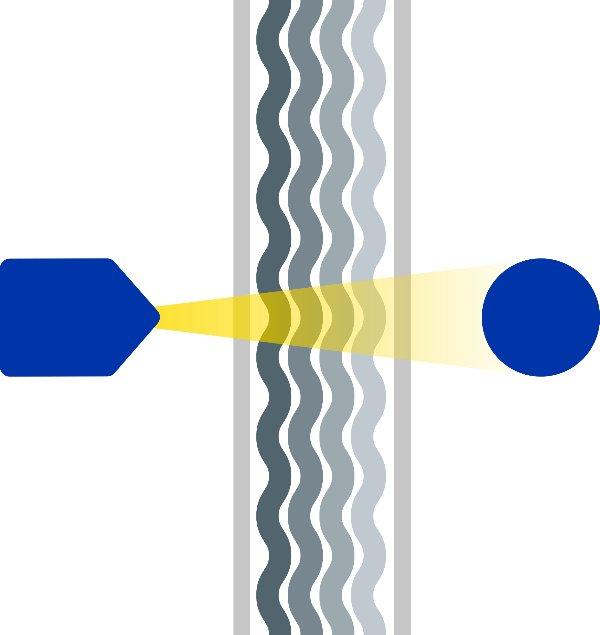

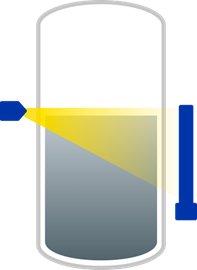

Concentration and density measurement on liquids

Concentration, density, or dry matter can be measured in a wide variety of products, continuous processes, pipelines, and vessels using the microwave measuring systems from Berthold Technologies. From the food industry to power plants and the pharmaceutical industry – the fields of application for our microwave systems are manifold and the selection of sensors is correspondingly large. Our special technical features, such as checking the plausibility of measured values or very high measurement and frequency dynamics, set new standards. The measuring principle The microwave measuring system uses the dielectric property of water. The measuring system generates microwaves that interact with the water molecules. This interaction causes an attenuation of the…

-

Konzentrations- und Dichtemessung an Flüssigkeiten

Mit den Mikrowellen-Messsystemen von Berthold Technologies können Konzentration, Dichte oder Trockenmasse in unterschiedlichsten Produkten, im laufenden Prozess, an Rohrleitungen oder Behältern gemessen werden. Von der Lebensmittelindustrie über Kraftwerke bis hin zu der Pharmaindustrie – die Einsatzgebiete unserer Mikrowellensysteme sind vielfältig und entsprechend groß ist auch die Auswahl an Sensoren. Unsere technischen Besonderheiten wie die Prüfung der Messwertplausibilität oder eine sehr hohe Mess- und Frequenzdynamik setzen neue Maßstäbe. Das Messprinzip Das Mikrowellenmesssystem nutzt die dielektrische Eigenschaft des Wassers. Das Messsystem generiert Mikrowellen, welche mit den Wassermolekülen interagieren. Diese Wechselwirkung verursacht eine Schwächung der Mikrowellenenergie, welche als Phasenverschiebung und Dämpfung detektiert werden kann. Da die Phasenverschiebungsund Dämpfungsänderung direkt proportional zum Wassergehalt im…

-

Radiometric measurement solutions for the petrochemical industry

In order to produce a variety of plastics and polymers, petrochemistry deals with the synthesis of hydrocarbon compounds, derived from the refining of crude oil and/or processing of natural gas. During the production of polymers, extreme conditions can occur, such as high-pressure and high-temperature. Thus, conventional density, level and level-switch measurement solutions can often not be applied or cannot withstand these extreme conditions.The experts for petrochemical measurement solutions Berthold‘s radiometric measuring systems are used where conventional measurement techniques fail. Berthold is the worldwide leading supplier of radiometric measurement systems for the petrochemical industry. Corrosive, abrasive, high-pressure, and high-temperature environments require a non-contacting technology that can withstand these conditions. Due to…

-

Density & Solids content in the thickener

Large volume thickening tanks are used in the mining industry to concentrate ore or minerals. Gravity settling drives the solid-liquid separation, which concentrates the solids at the bottom of the tank. The concentrated slurry is removed via an underflow outlet and should have a high solids content. However, care must be taken to monitor slurry solids content, as too high solids content can clog or damage pumps and pipes. The SmartSeries LB 414 has been designed for the harshest of environments and is best suited for density measurements in the rough mining industry in non-hazardous and non-explosive environments. Berthold‘s SmartSeries LB 414 The solids content in the underflow is monitored…

-

Density measurement from Berthold

Radiometric density measurement systems are used wherever conventional measurement techniques fail. Successful applications can be found in a wide variety of industries and especially where extreme process environments and related challenging measurement conditions prevail, such as extreme temperatures, high pressure, dust or corrosive or abrasive media. Berthold’s density measurement systems are used for continuous process monitoring on pipelines and in vessels. Due to the radiometric principle, density, concentration and solid content can be determined completely contact-free without changing or affecting the flow properties of the measured material. The measurement can be carried out on liquids and mixtures of all kinds, including acids, alkalis, solutions, emulsions and suspensions. It is also…

-

Level measurement from Berthold

Radiometric level measurements from Berthold are used in a wide variety of industries. Successful applications are primarily found where extreme process environments and thus demanding or difficult measuring conditions prevail. The non-contact measuring systems are not affected by extreme temperatures, high pressures or dusty environments. Even strong foam formationor aggressive substances, such as corrosive or abrasive media, are no problem for our level measurement systems. Measuring ranges from a few millimeters up to several meters can be realized. Minimization of extraneous influences Due to the measuring principle of radiometry, radiometric measurements can be influenced by various external influences.. These include, for example, interfering radiation, radioactive media or fluctuating gas densities.…