-

BUTTING achieves another milestone in Brazil

BUTTING offers its customers a unique blend of precision, technology and financial soundness. In 2010, the pipe manufacturer, owing to its outstanding production know-how, delivered mechanically lined pipes to its customers to be installed in Brazil’s ultra-deepwater fields. These pipes, worldwide also known as BuBi® pipes set a precedent for longevity and high performance in the face of very harsh conditions. Since then, BUTTING has continued to lead the market with unwavering dedication, delivering more than 500 kilometres of its proven state-of-the-art mechanically lined BuBi® pipes to Brazil. The company has marked another significant achievement in the Brazilian offshore market with the on-schedule delivery of 290 kilometres of mechanically lined…

-

Validation of BUTTING pipe certificates

It’s easy for criminals to forge documents these days. Every year, German companies suffer economic damage amounting to 56 billion euros through counterfeit brands and product piracy. BUTTING is committed to protecting its customers from counterfeit products, and now offers end users the option to conveniently check the authenticity of our pipe certificates online. From now on, the certificates of BUTTING pipes will be provided with a QR code that end users can use to validate the certificate on our website. If a suspicion of counterfeiting is confirmed, it is possible to have an individual inspection carried out by our quality assurance department. BUTTING has been committed to combating counterfeit…

-

Responsibility over generations: The DNA of our company

At BUTTING, we consider sustainability to be a central element of our ethical mission statement, which has been anchored in our family of employees since 1777. Our mission is to pass on a healthy company to future generations and to achieve climate neutrality by 2050. With this in mind, we recently published our first sustainability report for BUTTING in Knesebeck. Managing Director Dirk Meinecke emphasizes: "In order to achieve this goal, we consistently integrate social, ecological and financial aspects into our corporate strategy." One focus of our responsibility lies, for example, in the area of compliance management. This includes defining our Code of Conduct for employees, customers and suppliers. In…

-

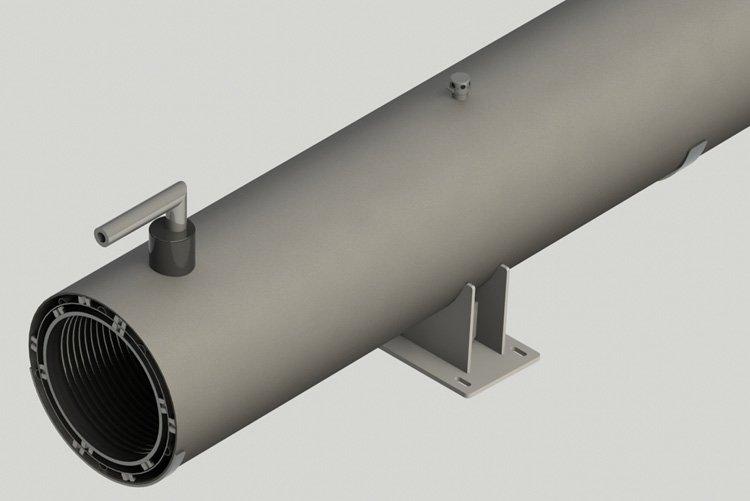

Cluster 5 Double Layer: Environmental protection on the high seas

BUTTING has already built a large number of SCR catalytic converters for MAN Energy Solutions. However, a new milestone has been achieved with the production of a massive Cluster 5 Double Layer. The SCR catalytic converters (SCR stands for Selective Catalytic Reduction) manufactured by BUTTING are used in cruise ships and cargo ships to reduce their nitrogen oxide emissions by up to 90 per cent. The clusters, ranging in size from 1 to 5, are produced for both high and low pressure ranges. So far this year, BUTTING has manufactured over 60 reactors. In an effort to generate economic benefits for its customers, the family business relocated its series production for SCR catalytic converters from…

-

E-methanol: BUTTING supplies for production plant

BUTTING recently booked another order for our green future: For an ambitious project in Scandinavia, a piping package was ordered via a partner in the stockholding steel trade. It is the largest project currently under construction for an e-methanol production plant in Europe. The plant is expected to produce several thousand metric tons of e-methanol per year and will go into operation as early as 2025. For BUTTING this also means realising the project in a short space of time. The scope of delivery includes pipes made of the materials 1.4307, 1.4541 and 1.4571 in sizes ranging from DN 150 to DN 500. To be able to deliver on time,…

-

BUTTING: Innovative in fusion energy

The global energy transition is gaining increasing attention. Companies are looking for innovative solutions to harness renewable energy sources. BUTTING, too, is actively involved in the promising field of fusion energy. Fusion energy is seen as a forward-looking approach to sustainable energy production. In this technology, atomic nuclei combine, releasing significant amounts of energy in the process. Compared to commonly used energy sources, fusion energy offers the potential for an almost limitless, clean and environmentally friendly energy source. Our extensive range of key technologies demonstrates our commitment to environmentally sustainable energy production. These technologies include vacuum-insulated piping components (VIP piping) in customised special designs for specific applications in fusion reactors,…

-

The pulp and paper industry: BUTTING accompanies gigantic conversion project.

. BUTTING Anlagenbau in Schwedt received a major order for the "O750 Oulu" project from Stora Enso in June. At the Oulu site in northern Finland, the former PM6 paper machine is being converted into a modern, high-performance production line for packaging board. The aim is for this to become the largest machine of its kind in Europe. After completion, the annual production volume is expected to be around 750,000 tonnes of the high-quality coated primary fibre board with a white or brown reverse side (FBB, CKB)[1]. The rebuilt plant is expected to start production in early 2025. For this project, BUTTING in Schwedt received the order for 128 container…

-

First vacuum-insulated piping manufactured in Knesebeck

In the middle of last year, BUTTING enjoyed its own premiere when for the first time vacuum insulated piping (VIP) was produced in single-part production at Knesebeck and then successfully delivered. A well-known industrial group had planned a flagship project with a Norwegian ferry company: the first hydrogen-powered ferry to move people and cars worldwide! VIP was needed in order to convert the liquid hydrogen into gaseous hydrogen during the driving process. BUTTING CryoTech, a member of the BUTTING Group, is one of the leading specialists in the field of VIP, based in Burgkirchen. Given the high-level testing requirements for this project, close collaboration between BUTTING CryoTech and BUTTING in…