-

camLine bringt Cornerstone 8.1 auf den Markt, um die Datenanalyse für Anwender zu verbessern

camLine, ein Spezialist für Hightech-Softwarelösungen in der Fertigungsindustrie, bringt mit Cornerstone 8.1 die neueste Version seiner renommierten Desktop-Anwendung für die technische Datenanalyse im industriellen Umfeld auf den Markt. Diese Version enthält viele neue Features und Funktionen, um die Erfahrung in der Versuchsplanung (DoE), der Datennavigation, dem Datenhandling und der grafischen Darstellung von Daten zu verbessern. Cornerstone ist ein flexibles Datenanalysewerkzeug für verschiedene Disziplinen und Branchen, darunter Fertigung, Forschung, Entwicklung, Qualitätssicherung und Bildung. Die heutige Weiterentwicklung der Version 8.1 wird von Statistikern in Diskussion mit Industriekunden vorangetrieben und macht es für Ingenieure kompakt und effizient, um schnellere Ergebnisse zu erzielen. Was ist neu in Cornerstone 8.1? Das Modul für die Versuchsplanung…

-

camLine Launches the New Cornerstone 8.1 to Improve Users’ Data Analysis Experience

camLine, a high-tech manufacturing software solutions specialist, launches Cornerstone 8.1, the latest version of their renowned desktop application for technical data analysis in the industrial field. This version comes with many new features and functions to enhance your experience in Design of Experiments (DoE), data navigation, data handling, and graphs in visualizing data storytelling. Cornerstone is a flexible data analysis tool for various disciplines and industries including manufacturing, research, development, quality assurance, and education. Today’s further development of version 8.1 is driven by statisticians in discussion with industrial clients, making it compact and efficient for engineers to achieve quicker results. What’s new in Cornerstone 8.1? The Design of Experiment (DoE)…

-

camLine erwirbt Softwareanbieter iCADA

camLine, ein Unternehmen von Elisa IndustrIQ und Spezialist für Softwarelösungen in der Hightech-Fertigung, hat seine führende Position als Anbieter von Halbleiterlösungen durch die Übernahme von iCADA, einem in Deutschland ansässigen Softwareunternehmen mit Schwerpunkt auf Halbleiter, weiter ausgebaut. iCADA bietet Lebenszykluslösungen für langlebige Betriebsmittel mit einem Fokus auf Retikeln und Prüfkarten. Durch die Übernahme stärkt camLine sein Portfolio mit führender Prozessexzellenz und ermöglicht es den Herstellern, ihre Prozesse zu optimieren, um so die Halbleiterindustrie nachhaltig voranzutreiben. iCADA ist ein führender Experte im Bereich der Halbleiterprozesse und Prozessautomatisierung mit Spezialisierung auf Lithographie, Metrologie und Materialmanagement. Mit einer 25-jährigen Erfolgsgeschichte in der Automatisierung von Halbleiterprozessen verfügt iCADA über zahlreiche, weltweite Installationen in der…

-

camLine Acquires Software Provider iCADA

camLine, an Elisa IndustrIQ company and high-tech manufacturing software solutions specialist, has further strengthened its leading position as a semiconductor solution provider with the acquisition of iCADA, the Germany-based semiconductor-focused software company. iCADA provides durable lifecycle solutions with a focus on reticles and probe cards. The acquisition strengthens camLine’s ability to deliver cutting-edge process excellence, empowering manufacturers to optimize processes and drive the semiconductor industry forward. iCADA is an expert in semiconductor processes and process automation, specializing in lithography, metrology, and material management. With a 25-year track record in semiconductor process automation, iCADA has multiple installations globally in semiconductor manufacturing. “This acquisition reinforces camLine’s dedication in supporting our customers with…

-

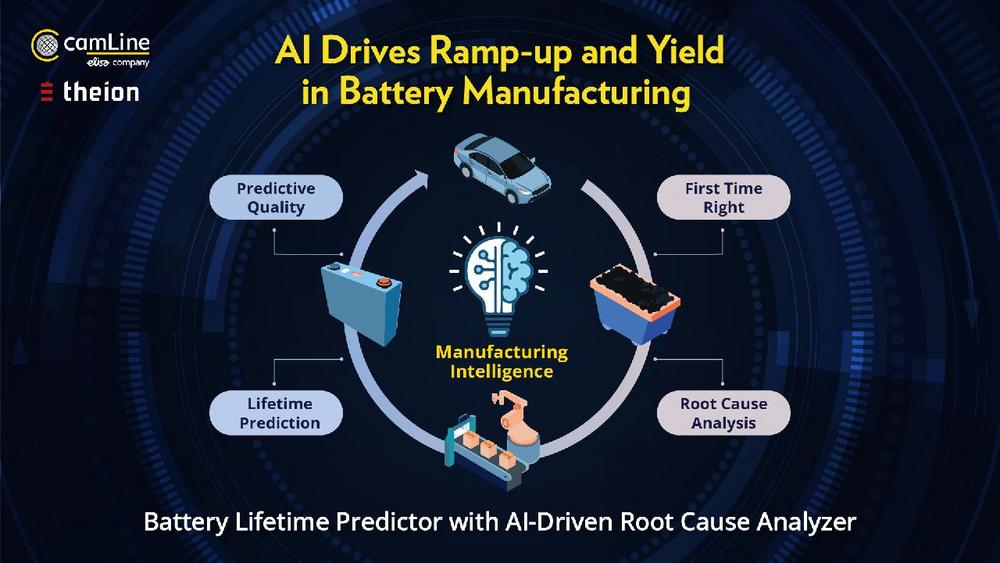

Game-Changer Alert: camLine and theion Reduce R&D Battery Testing Times by 98% Using AI

camLine, an Elisa IndustrlQ company and a leading provider of Manufacturing Execution System (MES), along with theion, a pioneering sulfur crystal battery company, are proud to announce their collaboration to implement AI-driven solutions that will accelerate the development of advanced battery technologies worldwide, revolutionizing the way battery manufacturers transition from lab-scale to mass production. Accelerate time to market with AI in battery manufacturing The collaboration brings together camLine’s cutting-edge AI tools, which are the Battery Lifetime Predictor and Root Cause Analyzer, with theion’s innovative approach to sulfur crystal battery technology. In a recent implementation, camLine’s Battery Lifetime Predictor has reduced theion’s R&D testing times from 42 days to just 15…

-

Romaric and Intel Join Forces to Revolutionize Factory Automation

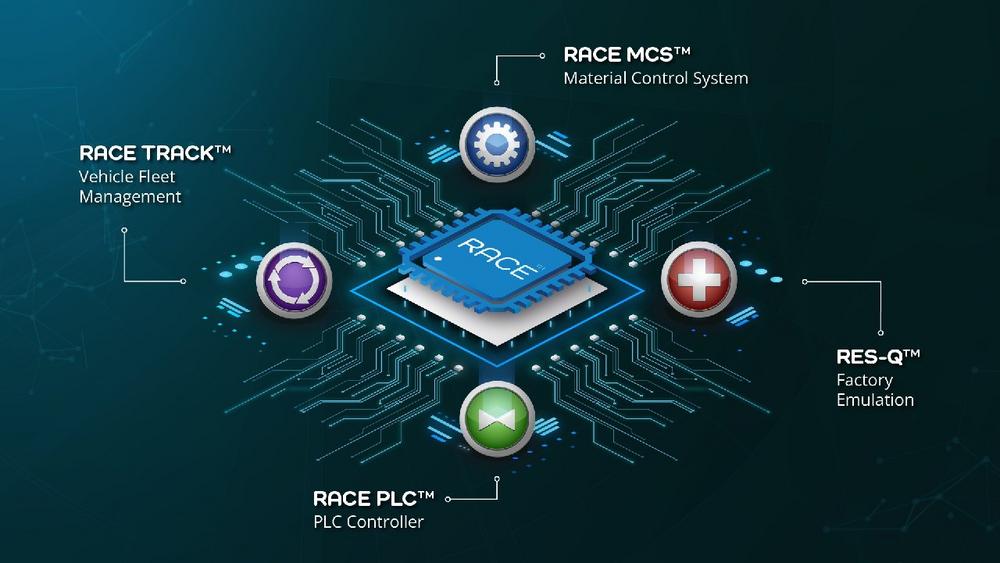

Romaric, a company of camLine Group and part of Elisa IndustrIQ, is excited to announce a transformative partnership with Intel. This collaboration aims to make factory operations smarter and more efficient by integrating Romaric’s robust material handling software with Intel’s advanced factory solutions. Manufacturers are increasingly facing challenges like bottlenecks in material handling, a lack of real-time data for decision-making, and inefficient use of resources. These issues highlight the need for advanced solutions that offer high-accurate simulations, and real-time optimization to boost productivity and competitiveness. The integration of the four products—Intel® Factory Pathfinder, Intel® Factory Recon, RACE MCS™ Material Control System, and RES-Q™ Factory Emulator, creates a comprehensive solution for…

-

ROMA MD™ is Now RACE MCS™: Expanding Beyond the Semiconductor Industry

Romaric, a part of the camLine group, is thrilled to announce the rebranding of the Romaric Material Dispatcher (ROMA MD™), the only third-generation Material Control System (MCS) in the semiconductor industry worldwide, to RACE MCS™. This marks a pivotal moment in over 2 decades of Romaric’s history, expanding the reach of MCS beyond the semiconductor industry. Redefining Material Control System Boundaries The name RACE MCS™ is derived from the Romaric Automation Control Engine (RACE™) and Material Control System, emphasizing the robust RACE™ engine powering the MCS. Transitioning from ROMA MD™ to RACE MCS™ reflects Romaric’s dedication to continuous growth, innovation, and entry into new markets. RACE MCS™ addresses the need…

-

camLine and Romaric Join Forces in SEMICON Taiwan 2024

camLine, a valued manufacturing software solutions provider specializing in digital transformation across the process line, is delighted to announce its attendance and participation at SEMICON Taiwan 2024. camLine will be accompanied by Romaric, a leading software provider in material control systems and intralogistics solutions, to showcase their end-to-end solutions following the recent acquisition. SEMICON Taiwan provides the platform for industry players to connect with the global microelectronics ecosystem for collaboration between various industries and institutions. It’s the perfect opportunity for prospects to connect and explore innovative solutions by camLine and Romaric in the microelectronics industry. Visit the camLine-Romaric booth in SEMICON Taiwan 2024 with the details below: Date: September 4…

-

Shaping Industry 5.0: camLine to Host High-Tech Manufacturing Forum

The international camLine forum 2024 event gathers passionate leading industry experts worldwide to share their exhilarating journey towards manufacturing excellence whilst embracing Industry 5.0 in this AI-driven digital era. The biannual manufacturing forum is hosted by leading software solutions for manufacturing excellence, camLine, and it will take place on September 11-12, 2024, at the International Congress Center Dresden in Germany. Under the theme "Define a Future with Digital Continuity: AI-Driven Operational Excellence," the event will feature industry experts discussing the latest trends and insights in manufacturing digitalization. Highlights of the event include use case presentations, live demonstrations, success story sharing, user group meetings, and networking opportunities—all in one place. Additionally,…

-

Innovation trifft Expertise: Das camLine High-Tech-Produktionsforum zu Industrie 5.0 lädt zum Dialog

Auf dem internationalen camLine forum 2024 versammeln sich weltweit führende Branchenexperten, um ihre neuesten Projekterfahrungen zum Thema Fertigungsexzellenz zu teilen und wie sie in einem von KI getriebenen Umfeld innovative Konzepte zu Industrie 5.0 realisieren. Das alle zwei Jahre stattfindende Produktionsforum wird von camLine ausgerichtet, einem führenden Anbieter von Softwarelösungen zur Steigerung der Fertigungsexzellenz. Es findet am 11. und 12. September 2024 erstmals im International Congress Center Dresden (ICD) in Deutschland statt. Unter dem Motto "Define a Future with Digital Continuity: AI Driven Operational Excellence" wird bei der Veranstaltung über die neuesten Trends und Einblicke in die Digitalisierung der Fertigung diskutiert. Highlights der Veranstaltung sind Use-Case-Präsentationen, Live-Demonstrationen, Erfolgsgeschichten, User-Group-Meetings und…