-

Finetech Showcases Advanced SMD Rework Solutions at Productronica 2023

With Productronica 2023 on the horizon, Finetech is gearing up to showcase its advanced SMD rework solutions at booth A4.181. Known for its reliable rework systems, Finetech is set to make electronics production more sustainable, resource-efficient, and less dependent on supply chains. Finetech’s advanced rework systems, based on hot air technology, target professional rework of electronic components and modules, adhering to IPC/JEDEC standards. This technology allows for the entire rework cycle to be implemented on a single machine. The hot gas rework systems support a wide range of SMD components, from small designs (008004) to massive BGAs. The precision and control of process parameters ensure any rework challenge is tackled…

-

Finetech Presents Tailored Die Attach Solutions at Productronica 2023

As the countdown to Productronica 2023 begins, Finetech is gearing up to showcase its cutting-edge manual and automatic die bonders at booth B2-403. With over 30 years of experience in high-precision micro assembly and advanced die attach, Finetech is a leading supplier in the industry. The company’s mission is clear: to bring your visions to life. Through close collaboration with customers, Finetech crafts tailored process and equipment solutions to meet individual customer application requirements. The modular die bonder hardware and software enable flexible machine configurations that can adapt to new challenges at any time. Finetech’s “prototype-to-production” approach facilitates seamless transitions from R&D to production, offering integrated, flexible, and cost-efficient product…

-

Finetech announces FINEPLACER® sigma purchase by long-established customer, Promex

Finetech, a leading provider of precision die-bonders, announces the Promex purchase of the FINEPLACER® sigma. This is the second FINEPLACER® system implemented by Promex, joining a FINEPLACER® pico system purchased in 2019. Finetech is excited to see how the new sigma system will enable Promex to expand manufacturing for their customers in areas such as automotive, biotech, medical and optical. Promex Industries, a Silicon Valley–based provider of advanced design, packaging, and microelectronics assembly services, today announced the next key addition to its die-bonding service capabilities: a Finetech FINEPLACER® sigma advanced sub-micron bonder. Designed to deliver high placement accuracy for an array of processes (flip chip, wafer-level packaging, package stacking, and chip-on-glass/flex/board, to name a few), the FINEPLACER® sigma…

-

30 Years „simply accurate“

Founded in 1992 as an East Berlin "start-up", today Finetech GmbH & Co. KG is a leading global manufacturer of placement, assembly and rework systems for customers in the microelectronics industry. This year, the company celebrates its 30th anniversary. It all started in a rented apartment in Berlin-Friedrichshain: shortly after German reunification, an East Berlin engineer – owner of an ingenious patent on how to align electronic components with each other with high precision – and two colleagues built and marketed the first placement and assembly system based on the so-called FINEPLACER® functional principle. The original FINEPLACER® was an amazingly simple platform with a swivel arm and a fixed optical beam splitter.…

-

30 Jahre „einfach genau“

1992 als Ost-Berliner „Start-up“ gegründet, ist die Finetech GmbH & Co. KG heute ein weltweit führender Hersteller von Platzier-, Montage- und Reworksystemen für Kunden in der Mikroelektronik. In diesem Jahr feiert das Unternehmen sein 30-jähriges Jubiläum. In einer Mietswohnung in Friedrichshain fing alles an: kurz nach der deutschen Wiedervereinigung baute und vermarktete ein Ost-Berliner Ingenieur – Inhaber eines genialen Patents, wie sich elektronische Bauteile hochgenau zueinander ausrichten ließen – zusammen mit zwei Mitstreitern das erste Platzier und Montagesystem mit dem sogenannten FINEPLACER® Funktionsprinzip. Der originale FINEPLACER® war eine verblüffend einfach konstruierte Plattform mit Schwenkarm und fest verbautem optischen Strahlteiler. Schon damals lautete die Devise „simply accurate“, und auch heute steht sie für…

-

Prototype-to-Production with Sub Micron Accuracy

Finetech’s high-accuracy placement and assembly systems support customers from the photonics and optoelectronics industry in cost-efficient product development and transfer to automated manufacturing. With the sub-micron table top flip-chip and die bonder FINEPLACER® lambda 2 and the production platform FINEPLACER® femto 2, the Berlin-based precision machine manufacturer offers integrated high-accuracy die attach equipment and process solutions for all product stages. Finetech has been supporting start-ups as well as global technology leaders for three decades in the development of innovative semiconductor products. The highly accurate sub-micron placement and assembly systems are a cornerstone of the Berlin-based mechanical engineering company’s portfolio – valued worldwide as versatile, cost-efficient and compact bonding platforms for…

-

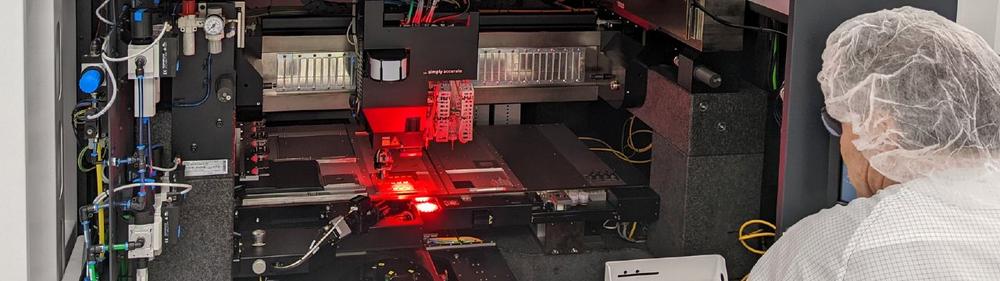

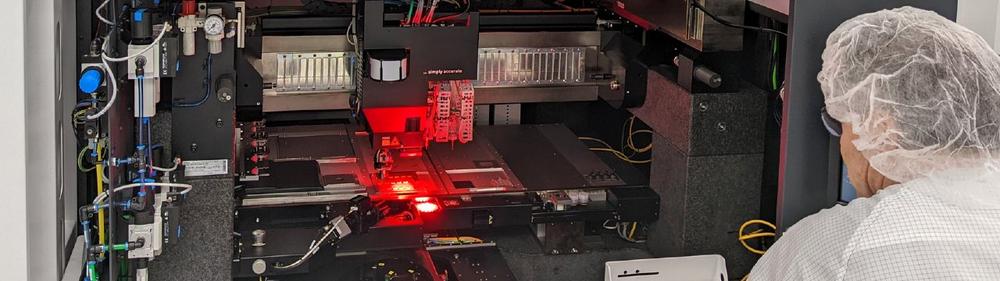

Automated Production of Diode Lasers for Medical, Industrial and Scientific Applications

With the help of a fully automated multi-chip bonder from Finetech, the Berlin-based laser specialists at Lumics have been able to improve reliability of their diode laser module manufacturing and to significantly increase production volume. Lumics GmbH, founded in 2000 and member of B.I.G. Berlin Industrial Group, is a key player for design and manufacturing of diode lasers used in demanding medical, industrial and scientific applications. In-house capabilities range from chip level up to fiber-coupled diode laser modules and turn-key laser systems based on single emitter technology. The product range comprises multi and single mode diode lasers available from 670nm to 1940nm, including the custom configurable LuOcean series and industry…

-

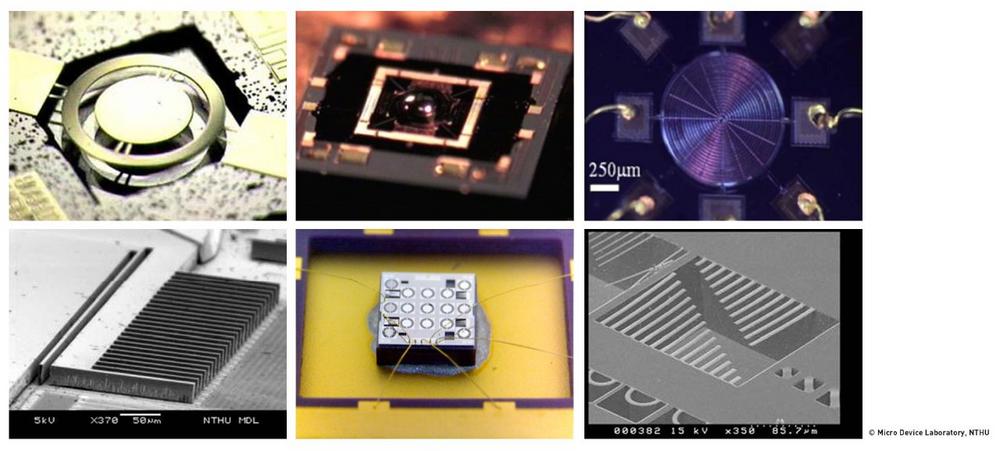

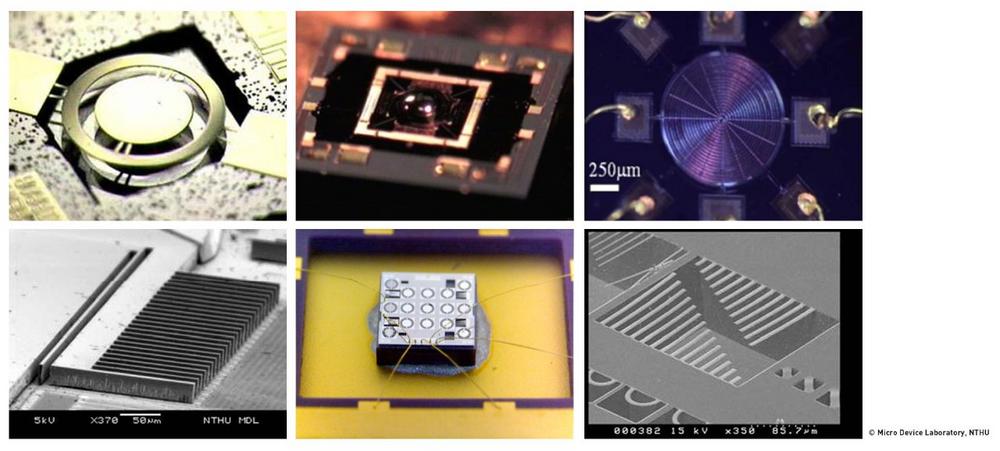

New Possibilities in R&D of Innovative MEMS Sensors

Dr. Shih-Wei Lin is a researcher and die bonding specialist at Professor Weileun Fang’s Micro Device Laboratory of the National Tsing Hua University, Taiwan. Main focus of the Micro Device Laboratory is the design, fabrication and testing of innovative micro sensors and actuators for applications in the fields of IoT, mobile phone and smart X. For example, this includes MEMS microphone devices and tactile force sensors for high-precision measuring tasks. In the past, building demonstrators and prototypes of MEMS sensors and actuators at the Micro Device Laboratory was done manually with microscope and tweezers, said Dr. Shih-Wei Lin. It somehow did the job, but was hardly reproducible and, of course, had many limitations,…

-

Automatische Produktion von Diodenlasern für Medizin, Industrie und Wissenschaft

Die Berliner Laserspezialisten von Lumics konnten mit Hilfe eines vollautomatischen Multi-Chip-Bonder von Finetech ihre Produktion von Diodenlasermodulen zuverlässiger und unabhängiger machen und den Fertigungsumfang deutlich erhöhen. Die Lumics GmbH, gegründet im Jahr 2000 und Mitglied der B.I.G. Berlin Industrial Group, ist ein wichtiger Akteur bei der Entwicklung und Herstellung von Diodenlasern für anspruchsvolle medizinische, industrielle und wissenschaftliche Anwendungen. Die hauseigenen Kompetenzen reichen von der Chipebene bis hin zu fasergekoppelten Diodenlasermodulen und schlüsselfertigen Lasersystemen auf Basis der Single-Emitter-Technologie. Die Produktpalette umfasst Multi- und Singlemode-Diodenlaser von 670nm bis 1940nm, einschließlich der kundenspezifisch konfigurierbaren LuOcean-Serie sowie Industriestandardlösungen. Die praxiserprobten Laser werden mit zusätzlichen Funktionen angeboten, die eine Anpassung an innovative Anwendungen in den Bereichen…

-

Neue Möglichkeiten für die Entwicklung innovativer MEMS-Sensoren

Dr. Shih-Wei Lin ist Forscher und Die-Bonding-Spezialist am Micro Device Laboratory von Professor Weileun Fang an der National Tsing Hua University (NTHU), Taiwan. Schwerpunkt der Arbeit des Micro Device Laboratory ist die Entwicklung, Herstellung und Erprobung innovativer Mikrosensoren und -aktoren für Anwendungen in den Bereichen IoT, Mobiltelefonie und Smart X. Dazu zählen beispielsweise MEMS-Mikrofone oder taktile Kraftsensoren für hochpräzise Messaufgaben. In der Vergangenheit wurden Demonstratoren und Prototypen von MEMS-Sensoren und -Aktoren im Micro Device Laboratory manuell mit Mikroskop und Pinzette aufgebaut, so Dr. Shih-Wei Lin. Das hat zwar irgendwie funktioniert, war aber kaum reproduzierbar und litt unter zahlreichen Einschränkungen, nicht zuletzt da moderne MEMS-Designs zwangsläufig immer kleiner und integrierter ausfallen. Um die Situation zu…