-

BUTTING recycles metal waste sustainably

BUTTING is one of the leading processors of stainless steels. As these materials are particularly resistant to corrosion and temperature, and therefore require little maintenance, they are particularly environmentally friendly. In addition, BUTTING is always looking for ways to optimise its business activities – including in the area of recycling metal waste. BUTTING in Knesebeck has been working closely with the recycling specialist Cronimet Envirotec since 2021. The aim is to reduce waste volumes and at the same time improve the recycling rate by reprocessing waste generated in the production process. Currently, residue from the cutting and grinding processes and dust from BUTTING filter systems are recycled by Cronimet Envirotec.…

-

LNG: Market relies on BUTTING pipes

The importance of liquefied natural gas (LNG) has grown significantly worldwide in recent months. Gas is also an important component for Germany to secure its energy supply. BUTTING has been supporting this industry for several decades – in addition to clad pipes for extracting gas (upstream), BUTTING also manufactures longitudinally welded stainless steel pipes for the treatment and processing sector (downstream). The German government’s LNG Acceleration Act is intended to drive forward the development of the LNG infrastructure. Projects include both land-based and floating terminals (floating storage and regasification units, or FSRUs). BUTTING has already supplied corrosion-resistant pipes in the materials 1.4462 / UNS S31803 (duplex), 1.4410 / UNS S32750…

-

SCHWANNER is now BUTTING CryoTech

Strengths complement each other – almost two years after its integration into the BUTTING Group, the Bavarian family business SCHWANNER is now operating under the new name "BUTTING CryoTech". "We have made a name for ourselves in the field of cryogenics in recent years thanks to our strong pioneering spirit and our high level of innovation for sustainable product solutions. But BUTTING is a brand that is known throughout the world. Our internationally operating customers in particular appreciate the security, financial strength and clout we have as a member of the BUTTING Group. We now want to express this clearly with our company name," says Marcel Bartels, Managing Director of…

-

The BUTTING Group – Ready for take-off, with a new crew

The BUTTING Group has reorganised their Aviation and Space division under the direction of Jörn Kubiak. With two new Business Development Managers and the planned start of a new Project Manager early 2023, the BUTTING Group are planning a new start to their offering. Following on from their success with their Aviation and Space customers the BUTTING Group, a family owned business with over 245 years of history, have made the strategic decision to increase their footprint within Aviation and Space. Building upon the tradition of excellence in the manufacturing of pipes, tanks and vessels in a range of industries and with the integration all the capabilities and specialities, the…

-

Sustainability in the cruise ship industry

MAN commissioned BUTTING to produce components ready for installation for the cruise ship MS Amadea operated by Phoenix Reisen. MS Amadea appears in the popular German TV series Das Traumschiff ("The Dream Ship"). It is also a pioneer in emission reduction: intelligent product solutions help to sustainably minimise pollutant emissions while maintaining engine performance. The new exhaust system includes selective catalytic reduction functionality. The catalytic converter converts the nitrogen oxides contained in the exhaust gas into water vapour and nitrogen. This process minimises pollutants and ensures efficient ship propulsion. BUTTING China shipped a prefabricated vessel to Knesebeck. The component for the ship’s new exhaust system was then assembled at the…

-

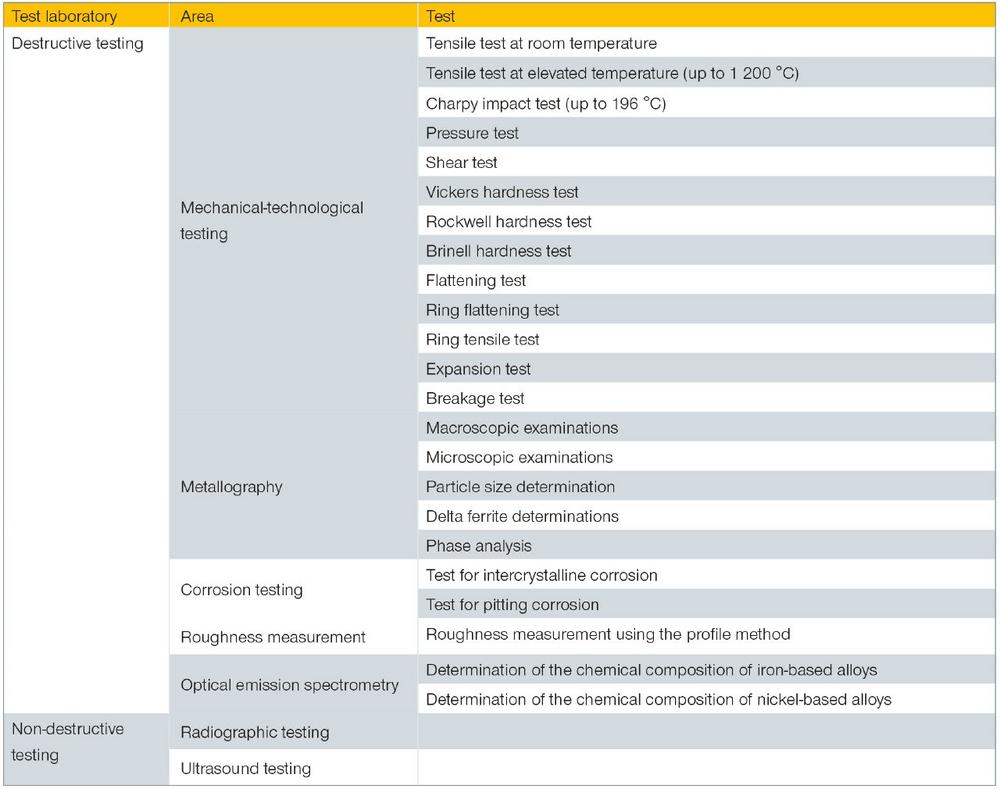

Impartial, independent, trustworthy

Participation in global trade is marked by increasing demands from our customers and end consumers – especially with regard to the verifiable quality of products. Their quality control should be impartial, independent and carried out with integrity. Against this background, BUTTING’s test laboratory has been certified according to DIN EN ISO / IEC 17025 since 1999. The German Accreditation Body (DAkkS) has authorised us to carry out the following testing: Mechanical-technological testing Mechanical testing Metallographic corrosion tests of metallic materials Material investigations of metals by means of optical spark emission spectrometry with steel and iron materials as well as nickel-based alloys Manual and mechanised non-destructive testing (radiographic and ultrasonic testing)…