-

INEOS Styrolution extends its line of sustainable SBC products by a 100% bio-attributed option

100% bio-attributed content Neutral to even negative carbon footprint ISCC PLUS certified mass balance approach INEOS Styrolution, the global leader in styrenics, has today announced the introduction of its first SBC[4] products produced from 100% bio-attributed feedstock. The new solution is available for INEOS Styrolution’s Styrolux® and Styroflex® product lines. In spring of 2021, Styrolux ECO and Styroflex ECO became INEOS Styrolution’s first specialty products based on bio-attributed styrene[5]. Today’s announcement goes one step further by producing these products from 100% bio-attributed feedstock. Both the styrene and the butadiene components in the SBC copolymer are from bio-attributed feedstock, kitchen and food waste and are not in competition with food production.…

-

INEOS Styrolution introduces first sustainable styrenics products with superior weathering resistance based on bio-attribution

Up to 50% bio-attributed content Up to 58% lower carbon footprint ISCC PLUS certified process INEOS Styrolution, the global leader in styrenics, has today announced the introduction of the company’s first sustainable ASA[1] solution. INEOS Styrolution’s Luran® S material is now also available as Luran® S ECO with up to 50% bio-attributed content. Luran S is a family of products for very demanding applications. It is particularly known for use in outdoor applications. Its UV resistance makes it the material of choice for a range of applications in the construction industry and exterior applications in automotive. Luran S is also selected for a range of applications in the Toys, Sports…

-

Indaver and INEOS Styrolution sign offtake agreement for recycled styrene monomer

Indaver’s depolymerisation plant to be the first of its kind in Europe From yoghurt pot to yoghurt pot – agreement closes the loop for polystyrene Indaver, a leading player in the European waste industry, and INEOS Styrolution, the global leader in styrenics, have signed an offtake agreement today giving INEOS Styrolution access to styrene monomer (“SM”) produced from post-consumer waste at Indaver’s planned depolymerisation plant. This agreement closes the loop towards a circular economy for polystyrene. It will enable INEOS Styrolution to produce polystyrene from recycled feedstock replacing styrene monomer produced from fossil feedstock. “The benefits are tremendous”, explains Dr. Alexander Glück., President EMEA at INEOS Styrolution. “We recognise plastics…

-

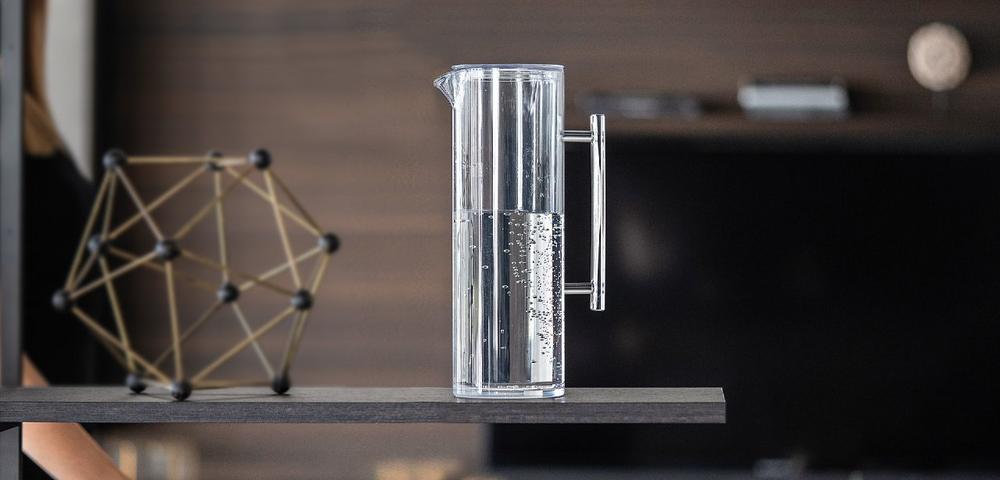

Fratelli Guzzini Selects Sustainable Styrenics Solution From INEOS Styrolution Based On Biomass Balanced Styrene From BASF

New Guzzini drinkware made from INEOS Styrolution’s sustainable ECO materials BASF to supply biomass balanced styrene as plastic feedstock Completely certified production process Fratelli Guzzini has today anounced it has selected a range of INEOS Styrolution’s sustainable NAS® ECO materials as materials of choice for its new range of drinkware solutions. NAS ECO is a styrene methyl methacrylate (SMMA) material, which is the result of a cooperation between INEOS Styrolution and BASF. It is built on BASF’s production of styrene monomer derived from renewable feedstock based on mass balance based processes. INEOS Styrolution uses the material as feedstock in its production of new sustainable styrenics solutions. First customer in…

-

Barnes™ and INEOS Styrolution collaborate on sustainable styrenics solutions

. · Focus on mechanically-recycled ABS Terluran® ECO · Material tests for optimal process and product quality repeatability and to enable customers to achieve their sustainable goals · Events in Denmark and the USA Molding Solutions, a strategic business unit within Barnes and pioneer of new technologies in injection molding, and INEOS Styrolution, the global leader in styrenics, today announced that they will collaborate on a sustainable ABS[1] solution that will make molding biomaterials and sustainable plastics easier. Molding Solutions and INEOS Styrolution will bundle their extensive expertise and unique technologies to make mechanically-recycled ABS solutions easier to process and achieve repeatable molded product quality with INEOS Styrolution’s Terluran® ECO…

-

Pal Packaging Selects Ineos Styrolution’s Mechanically Recycled Polystyrene for Sustainable Food Packaging

INEOS Styrolution, the global leader in styrenics, and Pal Packaging, a leading vertically integrated manufacturer and distributor of food packaging and foodservice products, announced today to partner on styrenics based sustainable food contact applications. Pal Packaging now incorporates the new mechanically recycled Styrolution® PS ECO, a 100% recycled polystyrene, in new food packaging solutions. Pal Packaging is a division of the Greece based Palamidis SA corporation. They are an innovative and reliable supplier of packers, processors and supermarkets across Europe. After successful trials with the new recycled material provided by INEOS Styrolution, the company was impressed with the ease of processing and the quality of the final product. Konstantinos Roumpos,…

-

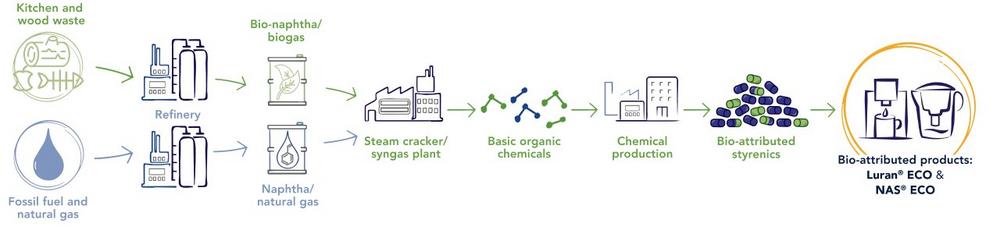

Up to 99% carbon footprint reduction from new INEOS Styrolution bio-attributed styrenics

. 77% to 99% carbon footprint reduction ISCC PLUS certified mass balance approach New drop-in solutions embrace NAS® ECO and Luran® ECO product ranges INEOS Styrolution, the global leader in styrenics, has introduced today new NAS® ECO and Luran® ECO sustainable drop-in solutions based on a mass balance process certified by ISCC PLUS. The products are based on styrene being produced using renewable feedstock that is not in competition with food production, such as kitchen waste and wood waste. The carbon footprint reduction for the new products varies between 77% and 99% when compared to the respective fossil-based products, depending on the amount of renewable feedstock used to produce a…

-

Ensinger acquires the StyLight® thermoplastic composite business from INEOS Styrolution

Ensinger and INEOS Styrolution announced the joint agreement today that Ensinger has acquired the StyLight® thermoplastic composite materials business of INEOS Styrolution. The acquisition adds an exclusive SAN based product range to Ensinger’s comprehensive thermoplastic composite portfolio. SAN based products bring many new thermoplastic composite possibilities to the market such as carbon, glass and natural (flax) based fibre products for aesthetic materials, semi structural, and over moulding applications to name a few. INEOS Styrolution developed and successfully launched the innovative StyLight product line at the K Show in 2016. Since then, the new solution has triggered a lot of interest and business with many customers across a range of industries.…

-

INEOS Styrolution press release – new ABS production in Wingles, France

INEOS Styrolution, the global leader in styrenics, has today announced the start of ABS[1] production in Wingles, France, having completed the conversion of an existing polystyrene line to the production of ABS. This move makes Wingles the company’s third ABS production site in Europe together with Antwerp, Belgium and Cologne, Germany. The ABS production capacity in Wingles will be 50,000 tonnes per year, to help meet the increased demand for ABS in Europe in industries such as Construction, Compounding, Household and Automotive. Dr. Alexander Glück, President EMEA, comments: “The new ABS plant in Wingles not only increases our overall ABS capacity in Europe, but it also allows us to provide…

-

INEOS Styrolution Receives ISCC Plus Certification in Europe

INEOS Styrolution, the global leader in styrenics, has announced today that two of its European production sites, namely Antwerp, Belgium and Ludwigshafen, Germany received the ISCC PLUS certification from ISCC (International Sustainability & Carbon Certification). The certification announced today paves the way for the audited production of recycling- and bio-attributed styrenics materials using a mass balance approach. The ISCC PLUS certificate for Antwerp addresses bio-attributed and recycled-attributed ABS[1], SBC[2] and polystyrene.The respective certificate for Ludwigshafen addresses bio-attributed and recycled-attributed SMMA[3], SAN[4] and ABS.This announcement follows a recent announcement for ISCC PLUS certification of several INEOS Styrolution sites in the Americas[5]. Further certifications for other European INEOS Styrolution production sites are expected soon.…