-

32nd International Colloquium Plastics Technology increases confidence in the innovative strength of the plastics industry

On February 28 and 29, 2024, the Institute for Plastics Processing (IKV) in Industry and Craft at RWTH Aachen University offered a lively forum for exchanging technical experiences and ideas. Some 600 participants from research and industry took advantage of the opportunity in the Aachen Eurogress and IKV’s technical service departments and laboratories to discuss the latest developments and technologies in the plastics segment. High-calibre plenary speakers, including VDI President Prof. Lutz Eckstein, were able to convince the audience of the innovative strength of the industry and the future of the engineering profession. Breaking through the stress of the many day-to-day events that are increasingly characterised by crisis reports, and…

-

FSK Innovation Award 2023: Eduard Kremer from IKV Aachen convinced the jury in the ‚Technology‘ category

He won in the ‚Young Talent – Technology‘ category. The award was announced during the FSK Symposium on 22nd November 2023. The FSK Innovation Award annually acknowledges outstanding innovations in the domains of design and aesthetics, technology, as well as process and chemical engineering, emphasizing sustainable approaches. The competition is open to young talents, companies, and professionals submitting projects related to foam plastics and polyurethanes. Eduard Kremer impressed the jury with his groundbreaking work on sensor-based process monitoring in PUR-RIM. His research allows for reducing the burden on the operator and significantly increasing the number of high-quality parts. By employing temperature, pressure, and DEA sensors, alongside considering ambient parameters such…

-

FSK-Innovationspreis 2023: Eduard Kremer vom IKV Aachen überzeugte die Jury in der Kategorie „Technologie“

Er gewann in der Kategorie Nachwuchs ̶ Technologie. Die Auszeichnung wurde im Rahmen der FSK-Fachtagung am 22.11.2023 in einem feierlichen Festakt bekanntgegeben. Der FSK-Innovationspreis würdigt jährlich herausragende Innovationen in den Bereichen Design und Gestaltung, Technologie sowie Verfahrens- und Chemietechnik, und legt dabei besonderes Augenmerk auf nachhaltige Ansätze. Der Wettbewerb steht Nachwuchskräften, Unternehmen und Fachkräften offen, die Projekte mit Bezug zu Schaumkunststoffen und Polyurethanen einreichen können. Eduard Kremer überzeugte die Jury mit seiner wegweisenden Arbeit zum Thema sensorbasierte Prozessüberwachung im PUR-RIM. Seine Forschung ermöglicht es, Lasten vom Bediener zu nehmen und die Anzahl der Gutteile signifikant zu erhöhen. Durch den Einsatz von Temperatur-, Druck- und DEA-Sensoren sowie der Berücksichtigung von Umgebungsparametern…

-

32nd International Colloquium Plastics Technology in Aachen – Professional exchange and research impulses for practice

The participants can look forward to a unique event that brings together the whole plastics sector. The Colloquium will take place on 28 and 29 February 2024, in Aachen. Varied lecture programme for an individual agenda: At the heart of the Colloquium will be the 15 lecture sessions, during which the current research topics at IKV will be presented. These sessions are consistent with IKV’s objective to carry out "Research for practical use", and are intensively dedicated to the perspectives and demands of the industry. Each of these sessions begins with a keynote speech from experienced industry representatives. This paves the way for the subsequent scientific papers, and creates the…

-

Sustainability – Put in extra shifts for the circular economy?

In order to move closer to the target of a comprehensive circular economy for plastics (and save its partners extra shifts), the Institute for Plastics Processing (IKV) in Industry and Craft at RWTH Aachen University is playing a leading role in research projects, in which, together with numerous partners, the value-added chain of plastics recyclate is being holistically optimised. The 32nd International Colloquium Plastics Technology will provide an insight into this. Through the consistent use of recyclate as a component of plastic products, it is possible to drastically reduce emissions (such as CO2 or the discharge of macroplastic and microplastic into waterways) and also to cut back on crude oil requirements.…

-

Medical technology – Innovative manufacturing chain for medical technology products

Due to the long innovation cycles until market maturity is reached and the complex regulations that have to be met, many medical devices are still being produced with outdated manufacturing processes that are often fraught with disadvantages. For this reason, in this MeKuMed cooperation project funded by the German Federal Ministry of Education and Research (BMBF), an innovative manufacturing process for optimising not only the production chain but also the product quality was developed for a hybrid microform fitted crimp cap. The process combines the laser-based metal processing of an aluminium thin sheet component – including a cutting, structuring and marking step – with a combined thermoforming/backmoulding process. The results…

-

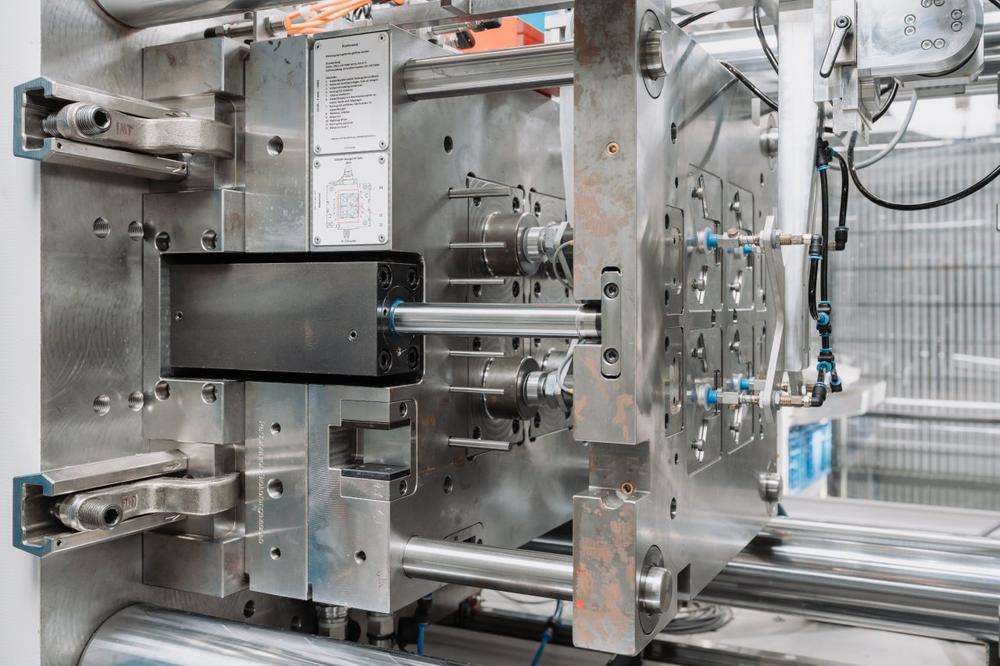

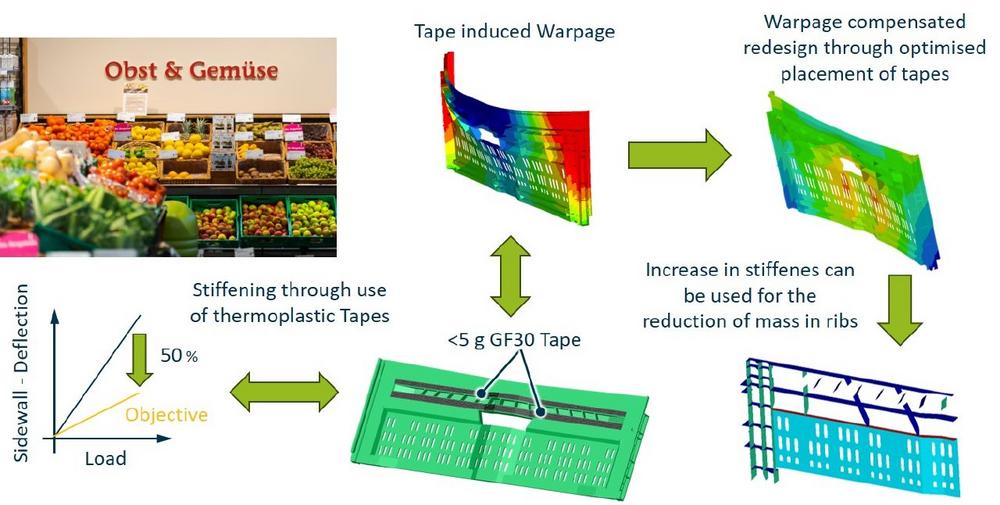

Lightweight construction – Efficient use of UD tapes in injection-moulded parts

In the research project "Tape Technology Transfer Hub" (T³-Hub), which has been running since December 2021, the Institute for Plastics Processing (IKV) in Industry and Craft at RWTH Aachen University, together with five other consortium partners, is examining how tape technology for conventional injection-moulded parts can be transferred to large-series production. The highly promising results will be presented during the 32nd International Colloquium Plastics Technology. Thermoplastic composite materials such as unidirectional tapes and composite sheet are being increasingly used above all in aerospace and the automotive industry because of their high potential for the production of composite parts with increased stiffness and strength. These materials, especially UD tapes, are also…

-

Hydrogen technologies – Plastics and their potential in the hydrogen industry

Green hydrogen is a key technology for implementing the energy turnaround. With this versatile energy source, renewable energies can be flexibly stored and converted into other forms of energy. At the same time, hydrogen plays a key role in the linking-up of various sectors, i.e. the interlinking of electricity systems, heat systems and mobility systems. For this reason, the topic of hydrogen has developed so much dynamism at European and international level in the last few years. The efficient scaling of technologies for the production of green hydrogen is an essential prerequisite for making hydrogen an economically sound part of the energy transition. This necessary and massive capacity expansion is…

-

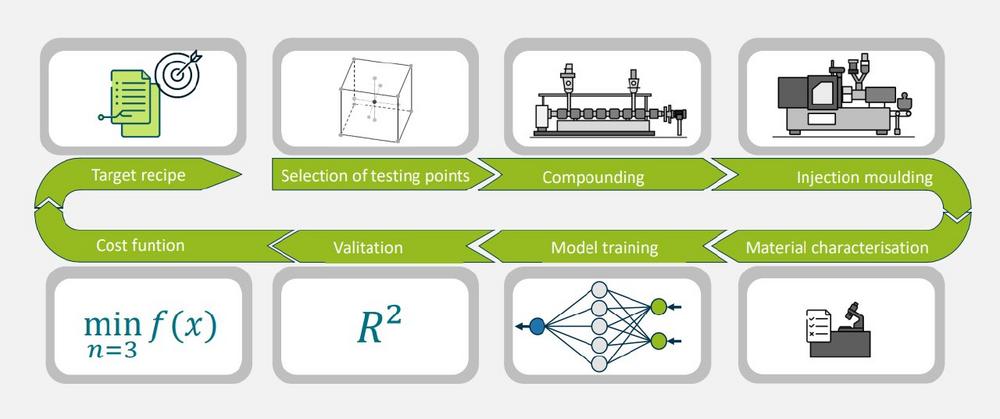

Digitalisation – Comprehensive solutions for plastics processing

A whole range of research projects enable the advancement of the the use of digital methods in plastics processing and tailor them to the industry. During the 32nd International Colloquium Plastics Technology, the IKV will provide a comprehensive insight into its capabilities in this field. The plastics industry faces the constant challenge of having to produce ever more economically and with higher quality. Digital solutions are a valuable support on many levels for the complexity of processes and process control: They accelerate operational processes such as approvals or logistics. They make it possible to efficiently provide and pass on information such as production orders or statistical evaluations. They provide knowledge…

-

Wasserstofftechnologien – Kunststoffe und ihr Potenzial in der Wasserstoffwirtschaft

Grüner Wasserstoff ist eine Schlüsseltechnologie zur Umsetzung der Energiewende. Mit dem vielfältig einsetzbaren Energieträger lassen sich erneuerbare Energien flexibel speichern und in andere Energieformen umwandeln. Gleichzeitig spielt Wasserstoff eine wesentliche Rolle bei der Sektorenkopplung, d. h. der Vernetzung von Strom-, Wärme- und Mobilitätssystemen. Darum hat das Thema Wasserstoff auf europäischer und internationaler Ebene in den letzten Jahren eine hohe Dynamik entwickelt. Die effiziente Skalierung von Technologien zur Erzeugung grünen Wasserstoffs ist eine wesentliche Voraussetzung dafür, Wasserstoff zu einem wirtschaftlich tragfähigen Teil der Energiewende zu machen. Für diesen notwendigen massiven Kapazitätsausbau braucht die Wasserstoffindustrie Kunststoffe. Wie sind Kunststoffe in der Wasserstofftechnologie einsetzen lassen und wie man die beiden Branchen zusammenbringen kann…