-

Simplifying load pin application sizing and more: Strainsert Inc. announce new load pin selection, sizing, traceability and fast delivery resources

Strainsert Inc., the leading USA load and force sensor designer and manufacturer, has recently announced new selection and configuration resources for load pin/clevis pin applications along with a new quick ship programme for its CPA series load pin product line. Also announced is an on-demand force sensor calibration certificate service. With local UK & Ireland sales and product support available through Strainsert’s distribution partner, Ixthus Instrumentation, these new resources and on-line tools will help customers select and configure load pins more effectively and efficiently, make product traceability measures more straightforward as well as identify products where urgent delivery is essential. Strainsert’s load pins or clevis pins and other force measurement…

-

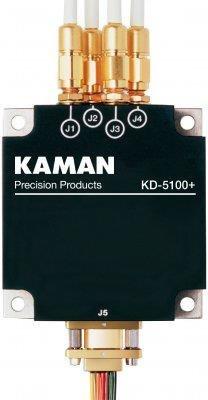

Fast and precise beam-steering mirror position feedback: Kaman’s new KD5100+ offers a high reliability specification for fast beam-steering mirror control systems

Kaman Precision Products Inc, the USA based designer and manufacturer of precision, inductive eddy current position measurement systems for the military/aerospace industries and many other challenging application areas has recently launched a high-reliability version of its fast beam-steering mirror measurement system. Available with full support from Kaman’s UK distribution partner – Ixthus Instrumentation – the upgraded KD-5100+ enables high-precision position feedback for control systems used in mirror steering and scanning tasks for laser communications on satellites and ground stations, airborne and shipborne directed energy systems and image stabilisation systems. Typical inductive sensor configurations used with the KD-5100+ include Kaman’s 15N or 20N series offering non contacting measurement ranges of +/-…

-

Force sensor and load cell applications in aerospace: Strainsert’s internal gauging process provides proven approach for load cell integrated components

Strainsert’s load cells, load pins, and other force sensing components and systems find use in a wide variety of measurement tasks across a wide range of industries. All applications require uncompromising levels of quality and reliability but none more so than the aerospace sector. Strainsert has a comprehensive standard product offering but characteristically for the aerospace industry, its custom design service comes to the fore – led by a proven multi-stage approach that is supported for UK customers by its exclusive distribution partner, Ixthus Instrumentation. Strainsert’s standard and custom force measurement products include a patented transducer design made possible by an innovative internal gauging process. Through its extensive in-house design…

-

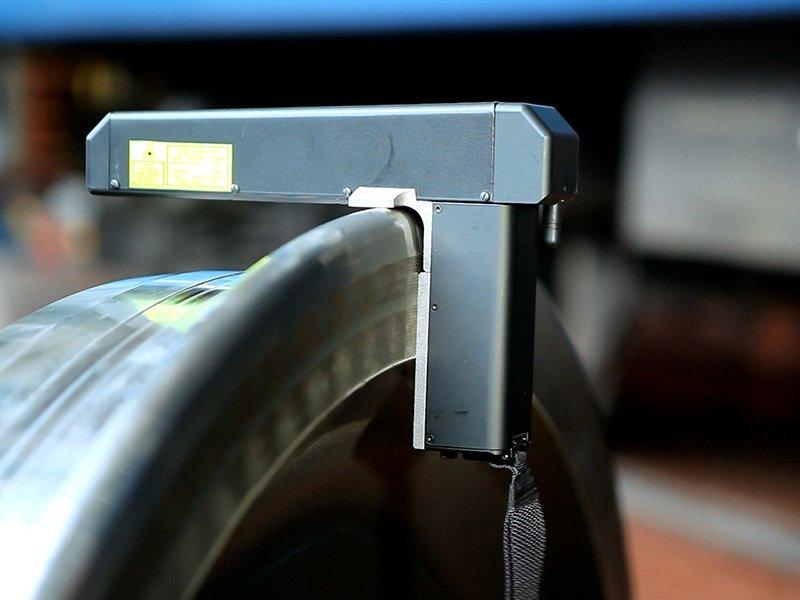

Ixthus Instrumentation offer complete support and calibration services for RIFTEK railway transport measurement instruments

Complementing its comprehensive range of optoelectronic measurement equipment and systems used across industry and research, RIFTEK LLC design and manufacture dedicated gauging instruments for the maintenance and in-situ inspection of safety-critical dimensional characteristics for all types of railway transport. Covering precision measurement of wheel profile and diameter, rail track and brake profile, backtoback wheel distance in addition to specialised systems for wheel set geometrical parameters, these worldclass instruments include portable laser-based hardware with integral displays, Bluetooth® and USB enabled devices for use with dedicated PDA dataloggers, and free PC software for data acquisition. RIFTEK, an ISO 9001:2015 certified company, is represented exclusively in the UK by Ixthus Instrumentation with complete…

-

Preventative Maintenance – Sensors and systems to monitor your plant and equipment

As a distribution partner for Metrix, the USA condition monitoring specialists, Northants based Ixthus Instrumentation provides preventative maintenance equipment for vital asset protection on large plant and rotating machinery such as compressors, pumps, turbines, cooling towers, gear boxes and more. Catastrophic failure of these types of machines often cause serious consequences for plant operation, including failure of other equipment, downtime with lost production revenue as well as safety hazards and potential health issues. Plant repair costs, where preventative maintenance has not been part of a strict regime, often run to far higher levels than the initial cost for asset protection. Catastrophic failure on large rotating and structural machinery is arguably…