-

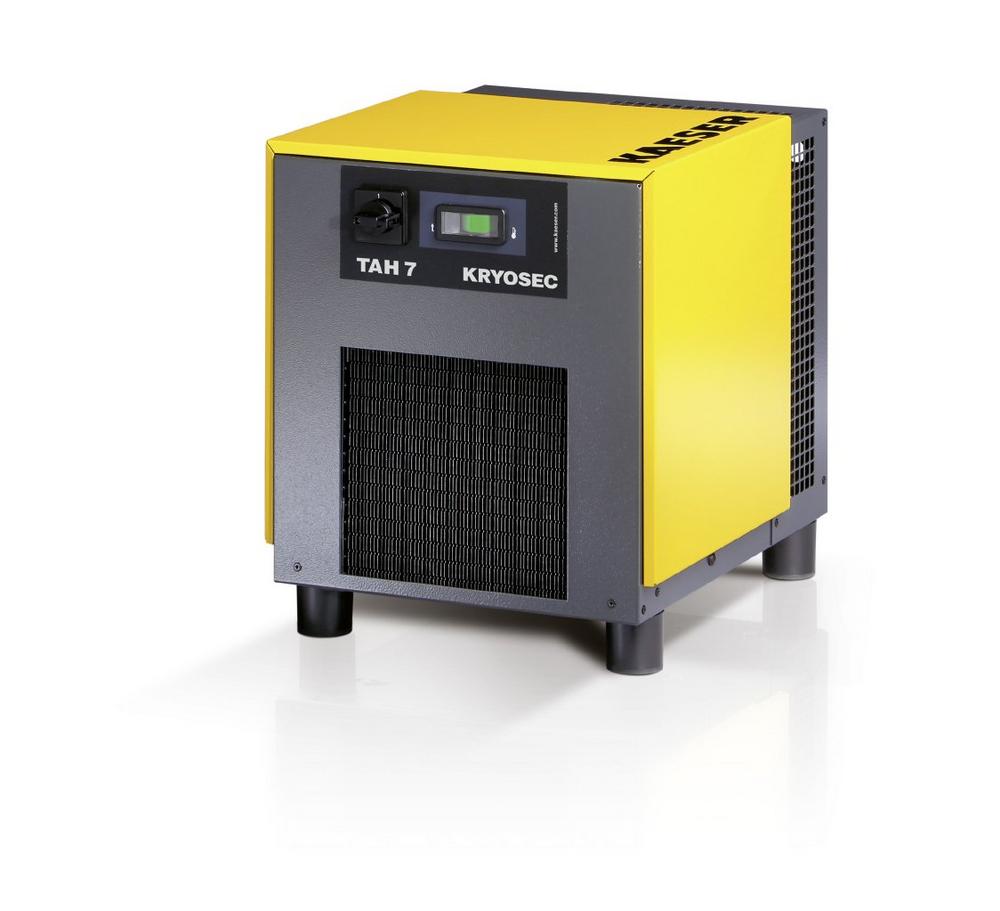

Reliable and exceptionally compact

With premium quality industrial design, the Kryosec refrigeration dryers from Kaeser Kompressoren deliver dependable drying performance in ambient temperatures up to +50 degrees Celsius – yet are highly efficient and exceptionally compact. The Kryosec series compressed air dryers from Kaeser Kompressoren provide dependable drying with minimal pressure differential even under the toughest of operating conditions for compressed air flow rates from 0.35 to 4.5 m³/min. Their impressive performance is made possible not only through generously dimensioned heat exchanger and refrigerant liquefaction surfaces, but also by dedicated cooling air flow. These features, combined with low-maintenance design, ensure highly efficient operation. All models meet applicable machinery safety requirements (EN 60204-1), including a…

-

Zuverlässig und sehr kompakt

Die Kryosec-Kältetrockner von Kaeser Kompressoren bestechen durch hochwertige Industriequalität und bieten zuverlässig trockene Druckluft bis zu einer Umgebungstemperatur von plus 50 Grad Celsius. Drucklufttrockner der Kryosec-Serie von Kaeser Kompressoren trocknen feuchte Druckluft mit sehr niedrigem Differenzdruck bei einem Volumenstrom von 0,35 bis 4,5 m³/min. Sie entfeuchten auch bei anspruchsvollen Betriebsbedingungen zuverlässig. Dazu tragen großzügig dimensionierte Wärmetauscher- und Kältemittelverflüssigungsflächen sowie die definierte Kühlluftführung bei. Dies und ihr wartungsarmer Aufbau bürgen für einen sehr wirtschaftlichen Betrieb. Die Trockner erfüllen die für Maschinen einzuhaltenden Sicherheitsanforderungen (EN 60204-1). Dazu gehören ein absperrbarer An/Aus-Schalter sowie die integrierte Netztrenneinrichtung. Dank ihrer hochwertigen Verarbeitung, der kompakten Bauweise und der hohen Zuverlässigkeit eignen sie sich zudem ideal für…

-

Maximum performance, minimal space requirement

Specifically designed for trade and craft applications, the SXC rotary screw compressor range from Kaeser Kompressoren combines exceptional efficiency and cost-effective performance with super-quiet compressed air generation, treatment and storage. Moreover, the SXC can help achieve annual savings of approximately € 800 compared with a conventional reciprocating compressor of equivalent power. Many trade and craft businesses still use a trusty old reciprocating compressor that has provided years of loyal service. That’s not a bad thing and says a lot about the quality of these machines. What isn’t so good however, is that although these compressors may reliably produce the necessary compressed air, they incur unacceptably high energy costs. This can…

-

Viel Druckluft auf wenig Platz

Wer Druckluft in der Werkstatt geräuscharm, energie- und kostensparend erzeugen möchte, braucht anwendergerechte Lösungen. Mit der platzsparenden Kompaktstation SXC stellt Kaeser Kompressoren ein speziell für Werkstätten entwickeltes Druckluft-Versorgungskonzept vor. Gegenüber einem in der Leistung vergleichbaren Kolbenkompressor lassen sich mit SXC pro Jahr bis zu rund 800 Euro Energiekosten einsparen. In so mancher Instandhaltungswerkstatt leistet heute noch ein älterer Kolbenkompressor auch nach vielen Jahren treue Dienste. Das ist gut und spricht für die Qualität der Maschine. Weniger gut ist jedoch, dass er zwar zuverlässig die benötigte Druckluft erzeugt, dabei aber oft zu viel Energie verbraucht. Jahr für Jahr können so unnötig hohe Stromkosten entstehen. Hinzu kommt, dass Kolbenkompressoren älterer Bauart oft…

-

Premium quality for trades and workshop applications

Anyone looking for a super-quiet, efficient and cost-effective supply of quality compressed air for their workshop requires a user-oriented solution. With the space-saving i.Comp 8 and 9 Tower T, Kaeser Kompressoren is proud to introduce a completely new compressed air supply concept that has been specifically developed with this field of use in mind. These units are powerful, compact, easy to maintain, efficient and much more. At the heart of the new i.Comp family is a new drive concept, which provides a multitude of advantages. The drive delivers the necessary power to cover the required compressed air demand with infinitely variable control. Needless to say, the reciprocating compressor itself is…

-

Premium-Qualität für das Handwerk

Wer Druckluft in der Werkstatt geräuscharm, energie- und kostensparend erzeugen möchte, braucht anwendergerechte Lösungen. Mit den platzsparenden Kompaktstationen i.Comp 8 und 9 Tower T stellt Kaeser Kompressoren ein völlig neues speziell für Werkstätten entwickeltes Druckluftversorgungskonzept vor. Er ist leistungsstark, kompakt, wartungsfreundlich, effizient und vieles mehr. Das Herzstück der neuen i.Comp Familie ist das neue Antriebskonzept, das eine Vielzahl von Vorteilen in sich vereinbart. So liefert der Antrieb bedarfsgerecht die Leistung, um den angeforderten Druckluftbedarf stufenlos zu decken. Der Kolbenkompressor selbst ist natürlich in gewohnter industrietauglicher Kaeser Qualität – Made in Germany. Selbstverständlich sind die Kolbenkompressoren der i.Comp Familie dauerlauffähig. Clevere Lösungen sorgen für einen herausragenden Füllgrad und damit verbunden höchste…

-

Space-saving, efficient compressed air production

No matter whether for a smaller business where space is at a premium, or a larger business requiring a decentralised compressed air supply, Kaeser’s compact Aircenter systems are the perfect choice for an efficient and environmentally-friendly source of quality compressed air. With a minimal footprint of approximately 1m², these energy saving systems are available for flow rates from 0.34 to 2.7 m³/min and also provide application-specific compressed air treatment and storage. All Aircenter models are characterised by their exceptional efficiency. At the heart of the two largest models, the Aircenter 22 (11 kW) and the Aircenter 25 (15 kW). is an optimised SK series rotary screw compressor from Kaeser. With…

-

Druckluft effizient und platzsparend erzeugen

Wer Druckluft in einem kleineren Betrieb mit beengten Platzverhältnissen oder in einem größeren Betrieb dezentral erzeugen will, kann dies heute auf sehr effiziente und umweltschonende Weise tun. Die Aircenter-Kompaktanlagen sind genau für diese Anforderungen ausgelegt. Auf minimaler Stellfläche erzeugen sie 0,34 bis 2,7 m³ Druckluft pro Minute energiesparend und geräuscharm, bereiten sie anwendungsgerecht auf und speichern sie. Herausragende Merkmale aller Aircenter-Anlagen sind ihr geringer Platzbedarf von etwa einem Quadratmeter und ihre hohe Effizienz. Das Herzstück der beiden größten Modelle Aircenter 22 (11 kW) und Aircenter 25 (15 kW) ist jeweils ein besonders leistungsfähiger und energiesparender Schraubenkompressor der optimierten SK-Baureihe. Mit einem maximalen Volumenstrom von 2,7 m³/min erzeugen die SK-Modelle bis…

-

Compressed air ahoy!

Dependable, energy-saving operation, coupled with highly reliable service, makes rotary screw compressors and blowers from Kaeser Kompressoren a perfect match for applications aboard ocean-going vessels. Highly efficient solutions are available, whatever your requirements. No matter whether it’s service air or compressed air for special applications such as nitrogen generation, Kaeser offers the perfect solution for all shipboard compressors. Reliability is a key feature of Kaeser’s marine compressors, which are certified by all the principal marine industry authorities (American Bureau of Shipping, Bureau Veritas, Det Norske Veritas, RINA, Lloyds’s Register, Korean Register, etc.). In addition to the reliability of its equipment, Kaeser also offers a Marine Service which ensures help is…

-

Support is always there

When it comes to compressed air on board a vessel, a reliable supply is one of the most important factors. Kaeser Marine Service ensures help is always available in the event of an issue, as well as for regular service intervals – wherever in the world you may be. Globally networked and coordinated centrally from Marine Head Office (MHO) in Coburg, Germany, qualified Kaeser service specialists are available if needed at the next port of call, as soon as the ship has berthed. Six specialised Marine Service Hubs (MSH) located in Houston, Coburg, Oslo, Busan, Shanghai and Singapore are also available to provide service around the world. Highly qualified Kaeser…