-

LEAD Intelligent Equipment Showcases Innovation and Industry Expertise at The Battery Show Middle East

Lead Intelligent Equipment ("LEAD"), a global provider of smart manufacturing solutions for battery production, made a strong impression at The Battery Show Middle East by contributing technical insights and strategic perspectives that are shaping the next era of battery manufacturing. A central voice in LEAD’s presence at the event was Dr. Hannes Weinmann, Head of the International Technical Center at LEAD Germany, who delivered a compelling keynote presentation and participated in a high-level panel discussion—sharing firsthand knowledge from years of hands-on experience in scaling gigafactory production. Leading Conversations Around Smart Manufacturing In his keynote, titled “Accelerating Factory Ramp-Up and Enhancing Production Efficiency with Innovative Manufacturing Solutions,” Dr. Weinmann outlined practical…

-

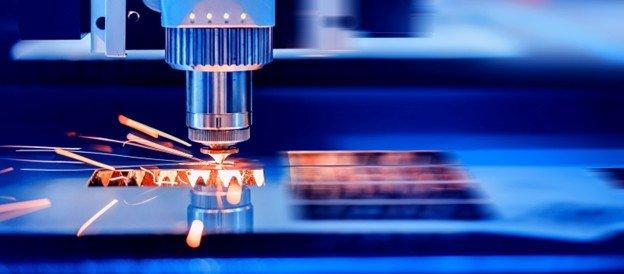

AI-Powered Welding Inspection: Lead Intelligent Equipment Enhances Battery Quality with Precision

Lead Intelligent Equipment ("LEAD"), a pioneer in intelligent automation and AI solutions for manufacturing, has successfully deployed its advanced AI-powered welding inspection technology, significantly enhancing battery quality control for battery manufacturers. Leveraging over 20 years of experience in lithium battery manufacturing, LEAD has developed an innovative AI welding discrimination model capable of adapting to complex production environments and accurately identifying welding anomalies in real-time. This breakthrough addresses critical pain points in the battery manufacturing sector, particularly ultrasonic welding, where traditional inspection methods face significant limitations. About the Customer The customer is a leading enterprise in new energy, recognized for its robust technical capabilities, large-scale production facilities, extensive customer network, and…

-

LEAD Successfully Delivers 100MW Perovskite Coating Machine, Driving Industry Advancement

Lead Intelligent Equipment (LEAD), a global leader in intelligent manufacturing solutions, has successfully developed and delivered a 100MW perovskite coating machine for a leading Chinese perovskite solar cell manufacturer. This cutting-edge equipment has facilitated the successful launch of multiple new products, reinforcing LEAD’s position at the forefront of the renewable energy industry. Proprietary Technology Enhancing Equipment Performance The newly developed 100MW perovskite photovoltaic pilot line is among the first of its kind in China, integrating LEAD’s proprietary large-width perovskite planar coating system. Designed for slot-die coating of perovskite layers, modification layers, and other functional components in perovskite production and pilot lines, this system incorporates several groundbreaking technologies, including: Dual-drive gantry…

-

LEAD Partners with a Leading South Korean Enterprise to Set a New Benchmark in Enhancing Accuracy for Digital Lithium-Ion Battery Manufacturing

Lead Intelligent Equipment (LEAD) has entered into a strategic partnership with a prominent South Korean enterprise to provide state-of-the-art cutting and stacking equipment for their high-end digital battery cell production line. This collaboration delivers a cutting-edge integrated solution, significantly enhancing manufacturing accuracy and setting a new industry standard. The partnership marks a pivotal breakthrough for LEAD in the digital manufacturing sector, solidifying its position at the forefront of technological innovation in lithium-ion battery production. The South Korean client is a globally renowned battery manufacturer with a substantial market share in both the electric vehicle (EV) and digital battery sectors. It is a key supplier to several world-class automotive and digital…

-

LEAD Secures WHG Certification, Boosting Equipment Exports to the European Market

Lead Intelligent Equipment (hereafter referred to as LEAD), a global leader in new energy intelligent manufacturing solutions, announced that it has officially obtained the Wasserhaushaltsgesetz (WHG) certification from TÜV Süd. This certification highlights the company’s exceptional technical expertise and professional capabilities in safety and compliance, while laying a solid foundation for efficient equipment export to Germany and the broader European market. The WHG certification is a key compliance requirement under Germany’s Federal Water Act, embodying the European Union’s water protection directives at a regional level. Attaining this certification confirms the company’s full compliance with German water regulations, supporting its international expansion, particularly in Germany, while showcasing its commitment to environmental…

-

LEAD Commits to Achieving Carbon Neutrality in Core Operations by 2035

Lead Intelligent Equipment (hereafter referred to as LEAD), a global leader in new energy intelligent manufacturing solutions, announces its plan for carbon neutrality. The company aims to reach peak carbon emissions in its core operations by the end of 2030 and achieve carbon neutrality in these operations by the end of 2035. Addressing climate change has become a shared goal among governments and businesses. The United Nations Environment Programme’s latest "Emissions Gap Report 2024" indicates that current climate policies will lead to a global average temperature increase of over 3°C by the end of this century compared to pre-industrial levels, more than double the target set in the Paris Agreement.…

-

LEADACE Intelligent Platform Boosts Quality and Efficiency for Electrolyte Filling Production Line of a top-notch Battery Manufacturer

Introduction With the rapid advancement of AI technology, its transformative potential in industrial applications is increasingly evident. Lead Intelligent Equipment (LEAD), leveraging its cutting-edge expertise in lithium battery AI and successful project implementations, partnered with a top EV and energy storage battery manufacturer to upgrade the electrolyte filling production line. This upgrade significantly enhanced both quality and efficiency, underscoring the value of AI-driven transformation. Client Overview The client is a leader in the EV battery and energy storage industry, renowned for launching innovative battery products recognized globally. With high production volumes and a strong reputation for technological advancement, the client sought a more efficient, precise, and stable solution for…

-

LEAD Intelligent Equipment Unveils Cutting-Edge Innovations at The Battery Show North America

LEAD Intelligent Equipment (LEAD), a leader in advanced manufacturing solutions, proudly announces its participation in the upcoming Battery Show North America, scheduled to take place from October 7-10, 2024, at Huntington Place, Detroit, MI. Visitors to LEAD’s booth will get a firsthand look at its latest innovations in battery manufacturing technology, reinforcing its commitment to driving efficiency, quality, and sustainability in the industry. Featured Product Innovations: Advanced Equipment for Battery Manufacturing: 30PPM Blade Cell Whole Line This newly developed assembly line features remarkable efficiency and precision. Equipped with advanced technologies such as CT inspection, laser welding, vacuum baking, and equal-pressure electrolyte filling, the line achieves high intelligence, low energy consumption,…

-

Lead Intelligent Equipment Joins the Volta Foundation: A New Era of Collaboration in Battery Innovation

Lead Intelligent Equipment (LEAD Intelligent) is thrilled to announce its membership in the prestigious Volta Foundation, the world’s largest network of battery professionals. This strategic move marks a significant milestone in LEAD Intelligent’s commitment to advancing battery technology and fostering innovation within the industry. As a proud member of the Volta Foundation, LEAD Intelligent is joining a global network of over 50,000 battery professionals and 160+ member companies. This affiliation opens doors to unparalleled opportunities for collaboration, resource sharing, and industry advocacy. By integrating LEAD Intelligent’s expertise with the Volta Foundation’s extensive network, LEAD Intelligent aims to contribute to and benefit from a collective effort toward groundbreaking advancements in battery…

-

Lead Intelligent Equipment to Showcase Innovations at The Battery Show Europe 2024

Lead Intelligent Equipment (LEAD) announces its participation in The Battery Show Europe 2024, set to take place from June 18th to 20th, 2024, in Stuttgart, Germany. This premier event will gather industry leaders, experts, and innovators from the battery and automotive sectors. At Booth 10-B20, LEAD will unveil the latest high-precision prismatic cell production line, featuring advanced stacking technology, formation, and aging solutions. Live demonstrations will highlight the integration of cutting-edge technologies such as IoT, Big Data, Artificial Intelligence, Cloud Computing, and Edge Computing into manufacturing processes and business functions, creating comprehensive smart factory solutions. Attendees can explore the meticulously engineered CTP production line, designed for seamless industrial integration, maximizing…