-

Maija milling discs – Milling by hand – With the hand angle milling cutter

Precise and relaxed working without much familiarization or lengthy training. Whether preparing, leveling / removing or opening a weld seam – no problem for these workers when working with the milling discs for the first time. Even the opening of a marked area that showed abnormalities during X-raying could be carried out precisely without prior practice. Chips instead of dust – metallically bright and no smearing: Pores and inclusions become visible when opening with the Maija milling discs. Über die Maija Frästechnik GmbH Maija-Frästechnik GmbH, founded in 2012, develops, produces and sells high-quality milling tools made of hard metal. The company owns the patent for milling discs, which was registered…

-

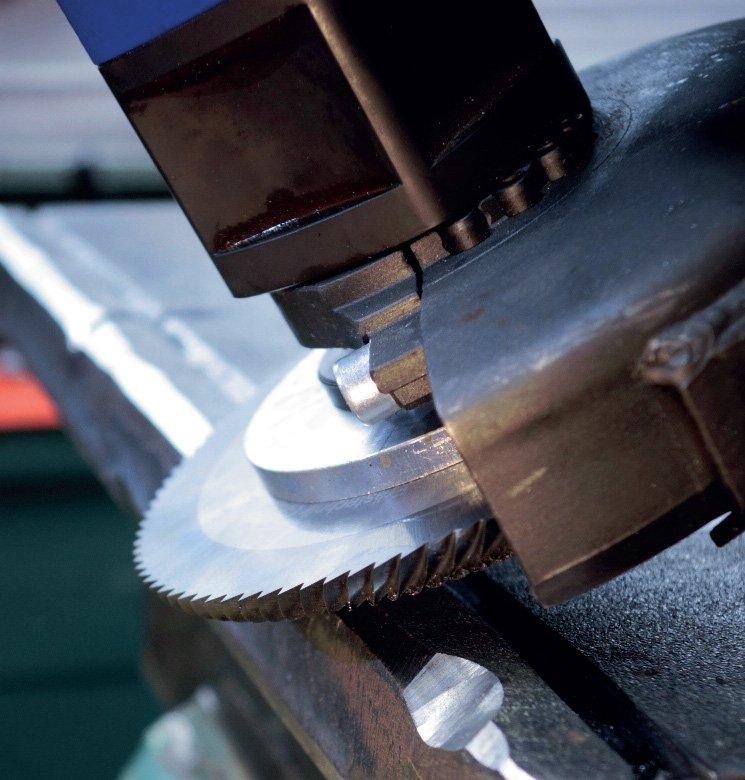

Preparation of a weld seam on a rotating stainless steel drum.

In the video, despite the distance to the worker, the difference between the unprocessed material (above the machine) and the bare metal result after processing with the MAIJA DoubleWorker (below the machine) is already visible. Once positioned, the worker only has to keep the machine with the MAIJA DoubleWorker on track to achieve perfect weld seam preparation on the rotating body. In this specific application, the unique positioning also makes it possible to integrate or implement the process as a (partially) automated process. The demonstration shows machining on a refuse collection vehicle, where no chrome-nickel dust may be produced when machining the material (1.4301). This problem is avoided by using…

-

MAIJA milling discs in automation and with heated components

The Maija milling discs can be used in automated areas, e.g. with a robot, in addition to the classic use on the manual angle milling cutter. For this purpose, MAIJA-Frästechnik GmbH offers planning and manufacturing according to customer requirements. The range extends from a simple adapter plate for integration into existing systems, to complete robot cells. In addition to simple tasks such as creating a chamfer or preparing a weld seam, fixtures for leveling weld seams over a longer distance can also be realized, for example. For this purpose, the "MAIJA roller milling carriage" can be combined with a robot which, guided on rails for example, can travel the full…

-

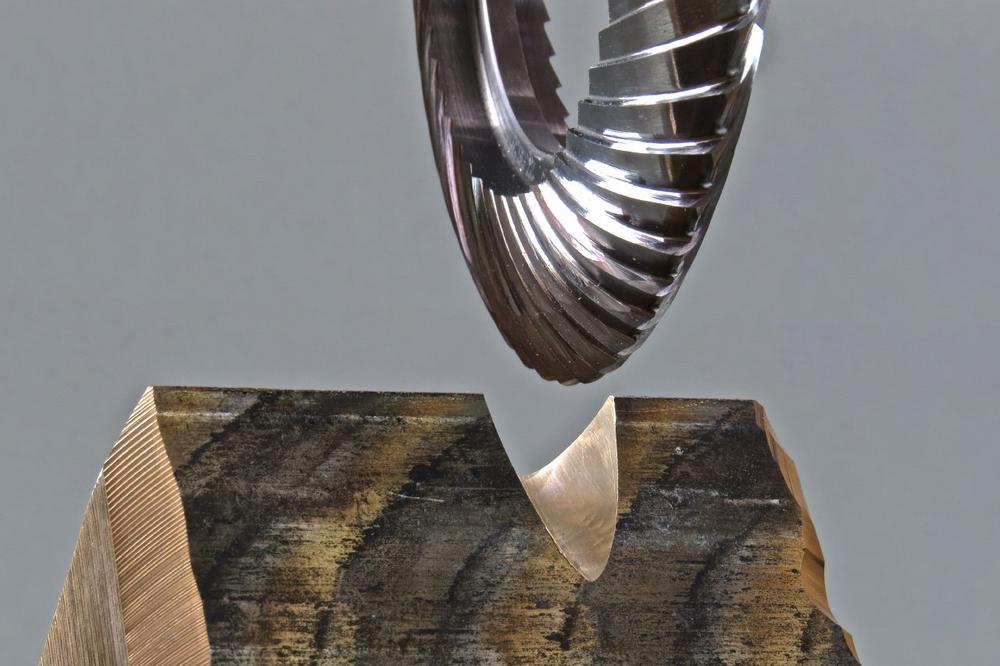

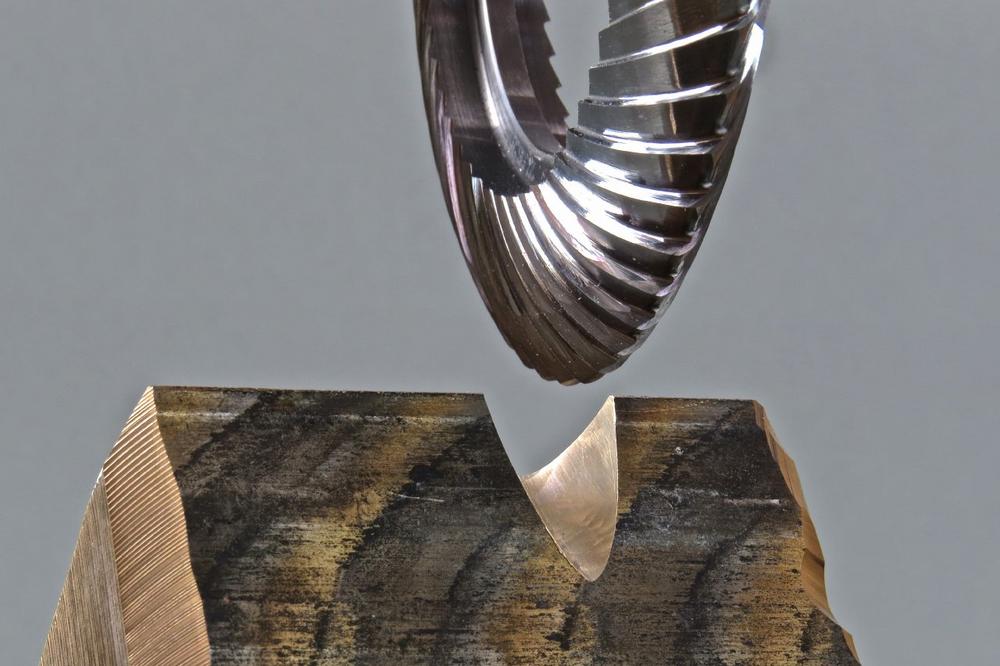

Die Maija-Fräsringe – gefertigt mit höchster Präzision

Wir bei der Maija-Frästechnik GmbH legen höchsten Wert auf die Präzision mit der unsere Werkzeuge gefertigt werden. Aus diesem Grund haben wir uns bereits zu Beginn der Entwicklung für die Zusammenarbeit mit der Firma Werkzeugdienst Oliver Fischer in Hoppegarten bei Berlin entschieden. Diese fertigt und schleift exklusiv für uns die Maija-Fräsringe. Im beigefügten Artikel der Fachzeitschrift „Forum“ des Fachverbands der Präzisionswerkzeugmechaniker (FDPW) stellt sich die Firma Werkzeugdienst Fischer vor, von der Entstehung bis zum aktuellen Einstieg in die Robotik. Über die Maija Frästechnik GmbH Maija-Frästechnik GmbH, founded in 2012, develops, produces and sells high-quality milling tools made of hard metal. The company owns the patent for milling discs, which was…

-

Milling instead of grinding – Milling wood

While so far primarily the machining of various metals was presented, the MAIJA milling discs are also suitable for other materials. Due to the chipping machining, the milling discs are perfectly suited for the machining of a wide variety of woods. The special feature: Nothing burns! This applies to both soft and hard woods, from spruce to oak and teak and beyond. In the linked videos, the machines operate at up to 12,000 rpm. The processing of spruce, oak and teak is shown there as an example. The milling discs can be used for machining in craft workshops, as well as for the creation of sculptures, for example. Über die…

-

Milling instead of grinding – with the hand angle miller – armor(ed) steel

At Maija-Frästechnik we have recently started documenting the use of the Maija Milling Discs in more specialized areas. In addition to the previously published videos on aluminium, steel, stainless steel and copper processing, the current videos show manual milling of more special materials, the processing of which has hardly or not at all been documented by us. Currently we are concentrating on making videos about milling hardfacing and armor steel. With the processing of armored steel, we show that even harder steels can be milled by hand with the Maija milling rings. So far we have published two videos on armor steel milling, these are attached to the report. Before…

-

Milling instead of grinding – with the hand angle miller – benefits for health, economy and ecology

Increasing sustainability, efficiency and security are three important aspects when using the Maija milling discs. The sustainability is so outstanding that the Maija milling discs were awarded the German resource efficiency price in 2015. (German resource efficiency price 2015, official website) The Maija milling discs are made of hard metal, and as such are completely recyclable. In addition, the milling discs can be sharpened up to seven times, and at the end, the no longer sharpenable disc still can be recycled. Each sharpen allows, depending on the processed material, a distance of up to 300 meters to be machined. The milling discs are intentionally made of hard metal and not…

-

Milling instead of grinding – with the hand angle miller – versatile and flexible

The milling discs are available in the three different kinds “milling disc”, “double sided milling disc” and “doubleworker”, which aim different areas of application. For all of those the following applies: The surfaces processed with the discs are metallic bright, and therefore prevent cavities while welding. While working, the discs produce neither (unhealthy) dust nor heat, and thus no structural changes that come with heat. The amount of material removed and the fineness of the result depend on the toothing. The fewer teeth, the coarser the chips and the greater the amount of material removed. The more teeth a disc has, the finer the chips and the smoother the surface,…

-

Milling instead of grinding – with the hand angle miller – for a perfect weld root preparation

While visiting a steel company in Wuppertal (Germany) the concept was formed to eliminate the grinding dust. In this company four employees have been working on ship bulkhead doors for shipyards in a production hall of around 150 m². Caused by the grinding with abrasive flap-wheels, grinding- and cutting discs, the air within the production hall was filled by a mixture of air and abrasive dust. Due to this, the workers have been covered with grinding dust, making breathing almost impossible. All tools, machines and furniture, even the lunch boxes and coffee pots have been black from the dust. In the 21st century often so called “silicosis”, even more chrome…