-

Introducing the Smallest Vibration-Damped Turning Tool by CTE – Cutting Tool Engineering

🌍 We’re excited to announce that MAQ has been selected by Cutting Tool Engineering | Magazine for our latest innovation! Introducing the world’s smallest vibration damped turning tool, capable of making 10 mm (3/8 inch) holes with a depth of up to 88 mm (3.46 inch). 🛠️✨ Join us for an upcoming webinar on micro machining, organized by Cutting Tool Engineering | Magazine where we’ll delve into the intricacies of this groundbreaking technology. Don’t miss out – sign up here: [Sign up webinar!] 📝🔗 Alan Richter, the author of the publication, shares more details on page 32 of the latest CTE Magazine. Check it out here: [http://dm.ctemag.com/] 📖🔍 At MAQ, we’re all…

-

Eastec Trade Show in the US

From May 16th to 18th we exhibited at Eastec in the US together with our partner Turpin Wholesale Inc. The show had a good turnover of people and you could see the interest after COVID. The MAQ booth had quite a lot of good activity and even if we did not get all of the visitors to our booth, we got some very good potential and existing customers. Thank you to everyone that came to our booth, we really enjoyed the week and spending time with you! We left Eastec with a boost in confidence and we keep the one sentence that we heard several times “- Thank you for…

-

Internal diamond burnishing – for surface finish below Ra 0.3 µm (16 µin)

Reaching a good surface finish has always been challenging, especially when it comes to internal machining. It’s even more difficult when the holes are deep and narrow which calls for a tool with a long overhang. To master also those processes MAQ is introducing its diamond burnishing line, with multiple cutter heads, with SL interface! With the new product line, you can effectively reach a surface finish at Ra 0.3 µm, even with tools at 15xD setup, see the above example of 25 mm product series. Seeing is believing so take a look at the video here: https://youtu.be/L1JwWMzy0FY. To be able to clearly see the result we this time do external turning.…

-

New record – Internal grooving 10xD setup with STMD

Curiosity has been our hallmark from the beginning, and we are always interested to know the physical limits of machining systems. Being told by the market to be very careful with internal grooving operation due to its vibration problem, we are today presenting our machining results of internal grooving at 10xD. Using an STMD M32-416 product, which is a standard steel bar damped with the STMD technology, with an SXFNR 322028 16 cutter head and 16 IR W 2.25 insert, we perform grooving at 10xD overhang length. The machined workpiece material is 4340 34 CrNiMo HRC 30. Thanks to the STMD technology, with its Self-Tuning capabilities, the tool adapts to…

-

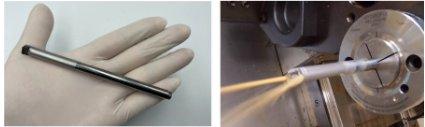

The Worlds Smallest Damped Turning Tool

Ladies and gentlemen, today we are presenting the world’s smallest vibration-damped turning tool! Ready to ship from MAQ! Some time ago we got an inquiry from our Partner that got an inquiry from a company with a serious challenge! They needed to do a turning operation inside a hole that is only 10mm in diameter and 80 mm deep. They had tried everything they could find but not even the best (most expensive(?)) carbide bar could get close to the surface finish they needed. Our Partner contacted us, and we decided to take on the challenge. Is it even possible to build such a small damped bar? We put in…

-

Der kleinste gedämpfte Drehmeißel der Welt

Der kleinste gedämpfte Drehmeißel der Welt Meine Damen und Herren, wir präsentieren Ihnen heute den kleinsten schwingungsgedämpften Drehmeißel der Welt! Sofort versandfertig von MAQ! Vor einiger Zeit erhielten wir eine Anfrage von unserem Partner, der eine Anfrage von einem Unternehmen mit einer ernsthaften Herausforderung erhielt! Es musste eine Dreharbeit in einem Loch mit einem Durchmesser von nur 10 mm und einer Tiefe von 80 mm durchgeführt werden. Sie hatten alles ausprobiert, was sie finden konnten, aber nicht einmal mit der besten (teuersten(?)) Hartmetallstange konnte die gewünschte Oberflächenqualität annähernd erreicht werden. Unser Partner kontaktierte uns und wir beschlossen, die Herausforderung anzunehmen. Ist es überhaupt möglich, eine so kleine gedämpfte Stange zu…

-

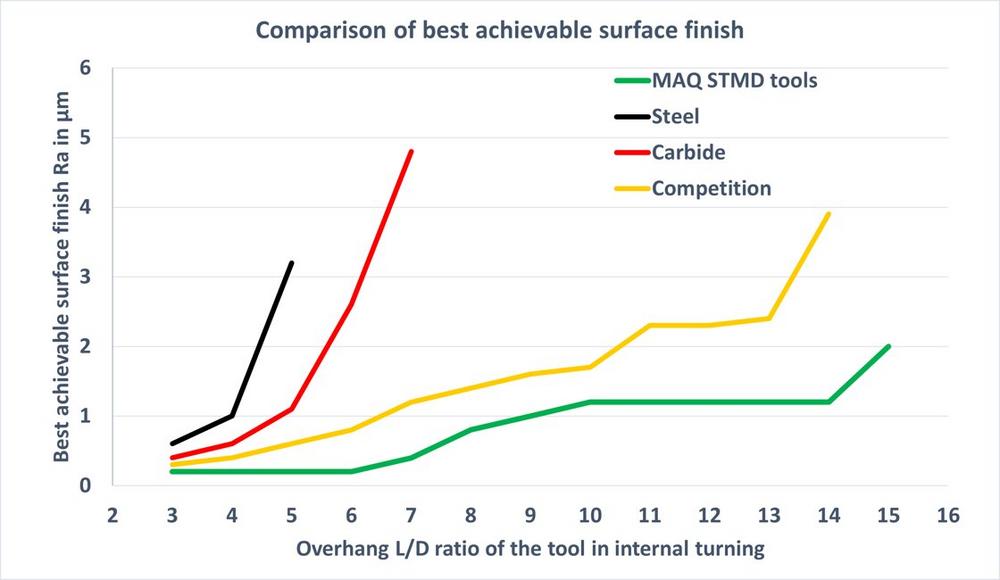

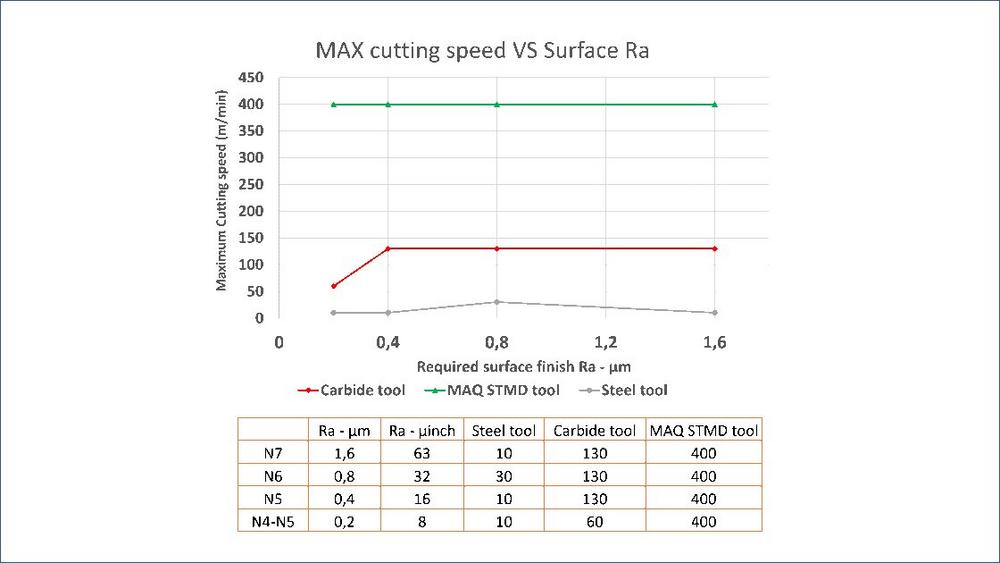

Achieve the best possible surface finish as fast as possible!

The surface finish of a component affects both its appearance and its functionality. Certain types of components need to have a surface texture finish, such as for their gripping function, and that is not the topic we talk about today. We will focus on the surface finish in terms of surface quality and accuracy, which have a detrimental impact on a component’s service life. The surface finish of a component affects not only its appearance but also its functioning life and quality. A smoother surface finish has the following advantages: less tendency to form cracks with fatigue. lower friction with better lubricity. better corrosion resistance with fewer surface defects. higher…

-

Mit MAQ STMD und Wiper Edge können Sie das Schleifen überspringen!

Maße, Toleranzen und Oberflächengüte sind die Hauptkriterien für einen Maschinenauftrag. Unser Ziel ist es, diese drei Bedingungen so schnell wie möglich zu erfüllen. Wiper Edge ist eine Erfindung, die es ermöglicht, beim Drehen eine geschliffene Oberfläche zu erzielen, indem sie die gezackten Spitzen einer gedrehten Oberfläche entfernt. Die spezielle Funktion von Wiper Edge begrenzt ihre Einsatzmöglichkeiten, da sie die Vibrationen bei der Bearbeitung natürlich erhöht. Aus diesem Grund wird oft darauf hingewiesen, dass WIPER Edge nur empfohlen wird, wenn es keine Vibrationen gibt. Ein Arbeitsstück von einer Drehmaschine zu einer Schleifmaschine zu transportieren, um die Anforderungen zu erfüllen, ist teuer und zeitaufwändig. Auch aus Sicht der „Energieeinsparung“ ist das Drehen…

-

Skip grinding with MAQ STMD and Wiper edge!

Dimension, tolerance, and surface finish are the three main requirements of a machining job. The goal is to satisfy these three requirements as fast as possible. Wiper edge was invented with the purpose of achieving a grinding surface finish in a turning operation by removing the scalloped tops of a turned surface. The specific Wiper edge feature is limiting its applications because it naturally increases vibrations in machining. Therefore, we often see a disclaim that WIPER edge is only recommended when there are no vibrations. Forced to move a workpiece from a turning machine to a grinding machine to meet the requirements, grinding is expensive and time-consuming. Also, from an…