-

Michell Bearings‘ Unique Capability a Success for Nuclear Station Blackout

In what is thought to be one of the world’s first successful bearing run downs, the test demonstrated the bearing’s ability to survive a station blackout condition without the use of an externally powered high pressure oil injection system. Failure of the on-site power generators concurrent with the loss of offsite power ultimately results in a station blackout condition as there is no on-site electricity available to power the high pressure oil injection system. In order to meet testing requirements, the bearing must be able to run down to a stop, under full load, and restart without any subsequent intervention. As part of the contract to supply six thrust and…

-

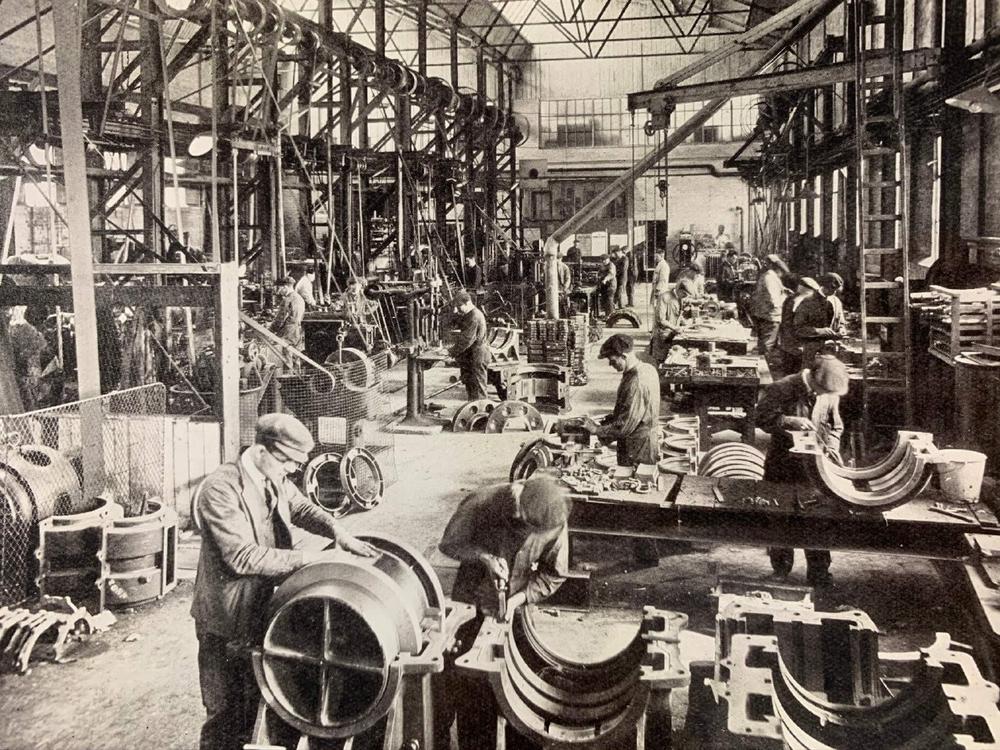

Bearing manufacturer Michell Bearings celebrates 100 years

In 1905, prior to the incorporation of Michell Bearings, founder A.G.M Michell registered patents in Britain and Australia for his tilting pad bearing invention, a concept which is widely used around the world today. Now employing 182 people from manufacturing sites in the UK and India, as well as a global sales network, Michell Bearings began life with co-ownership between A.G.M Michell and Henry Thornton Newbigin, as well as four major shipbuilders in the North East of England; Cammell Laird & Co., Vickers, John Brown & Co. and Fairfield Shipbuilding and Engineering Co. The adoption of Michell’s tilting pad thrust block was revolutionary during the First World War. By the end…

-

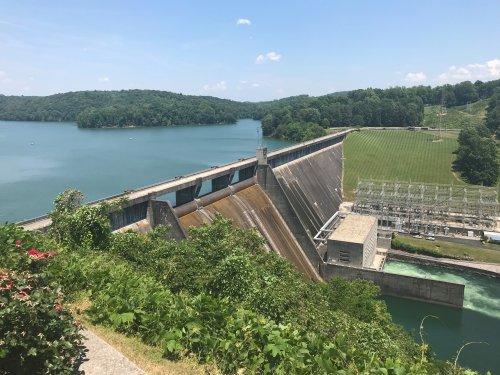

PTFE thrust bearing conversion improves operations at hydropower station

Constructed in the mid-1930s, the Norris Dam was the first major project for the Tennessee Valley Authority (TVA). Its purpose was to bring economic development to the region and control the flooding that had long plagued the Valley. TVA worked with Michell Bearings after experiencing numerous thrust bearing failures over the life of one of the two generator units. The failures of the original white metal bearings resulted in excessive downtime and associated loss of revenue. Michell Bearings was awarded a design contract to investigate the potential problems with the 1930’s design, which had been subject to various attempts over the years to improve reliability. The engineers at Michell Bearings…