-

The many advantages of Montech’s LTE modular transfer system

Montech’s LTE transfer system is a versatile and modular solution for automating material flows in production environments. With its numerous customizable components, it offers the greatest flexibility and efficiency. Montech Conveyors Corp. offers state-of-the-art solutions in the form of conveyor and framing systems that ensure a continuous and reliable material flow. The company specializes in the industrialization and standardization of state-of-the-art, unusual belt conveyors, transfer systems, and innovative aluminum framing systems. The LTE transfer system enables the feeding, unloading, storage, separation, and positioning of workpieces in an optimal way. It is designed to transport workpieces through different workstations automatically according to their assembly process. The workpieces are fixed on robust,…

-

The many advantages of Montech’s LTE modular transfer system

Montech’s LTE transfer system is a versatile and modular solution for automating material flows in production environments. With its numerous customizable components, it offers the greatest flexibility and efficiency. Montech Conveyors Corp. offers state-of-the-art solutions in the form of conveyor and framing systems that ensure a continuous and reliable material flow. The company specializes in the industrialization and standardization of state-of-the-art, unusual belt conveyors, transfer systems, and innovative aluminum framing systems. The LTE transfer system enables the feeding, unloading, storage, separation, and positioning of workpieces in an optimal way. It is designed to transport workpieces through different workstations automatically according to their assembly process. The workpieces are fixed on robust,…

-

Cleanroom conveyors are key to flawless production

Whether in the pharmaceutical industry, electronics production, medical technology, or food production – cleanrooms play a central role wherever the highest product quality is required. They protect sensitive processes from contamination and thus ensure the functionality and safety of the products. To achieve this, all components used must meet the highest requirements – especially the conveyor technology, which must transport materials precisely, reliably, and with extremely low particle output. Cleanrooms are indispensable in many high-tech industries: Medical devices such as catheters, syringes, and blood bags, for example, must be manufactured and moved under controlled conditions to ensure sterility. In semiconductor manufacturing, even microscopically small dust particles can lead to failures…

-

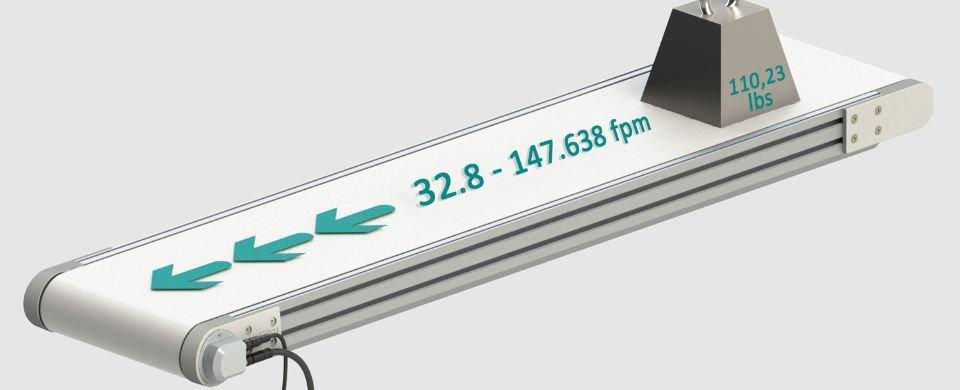

Improved and New Drive Units for Montech’s TB40 Belt conveyors

With a targeted redesign, Montech has further developed the drive units of the TB40 belt conveyor. In addition to introducing a third gearbox version for lighter loads with higher conveying speeds, the connection layout has been specifically improved. Montech has specialized for over 60 years in the industrialization and standardization of advanced and exceptional conveyors, transfer systems, and innovative aluminum framing systems. The technology company is constantly striving to improve its products and find new innovative solutions. With the redesign of the TB40 belt conveyor’s drive units, it has optimized them and now offers an even more targeted product range. New connection layout for more protection and flexibility The motor…

-

Efficient, hygienic, and precise Montech offers conveyor technology for pharmaceutical production

The pharmaceutical industry poses the highest demands for precision, cleanliness, and speed. Montech AG faces these challenges with specially developed conveyor technology that ensures safe, efficient, and error-free processing of pharmaceuticals and medical devices. As a leading technology company with over 60 years of experience in industrializing and standardizing belt conveyors and transfer systems, Montech offers solutions that are optimally adapted to the high standards of pharmaceutical and medical technology. "Our innovative conveyor systems improve both efficiency and quality assurance in sensitive production environments and are suitable for a wide range of applications," says Daniel Pauli, CEO of Montech AG. Blister packaging and sealing systems under control On the packaging…

-

60 Years of Montech: Innovation Born from Experience

Montech celebrated its 60th anniversary this year. The technology company looks back on an impressive company history and is optimistic about the future. Montech was founded as a system manufacturer for the watch industry in 1964. Today, it is a leading supplier of belt conveyors, aluminum framing systems, and transfer systems. This is due to the company’s clear values and principles. Customer orientation, innovation, quality, and precision have always been the focus of attention: "We act creatively, flexibly, and responsibly and actively promote the development of our employees," says Daniel Pauli, CEO of Montech AG. From system engineering to the component business When Montech moved away from system engineering and…

-

Expandable range of belt conveyors for fuel cell production

Production lines for energy converters such as fuel, battery, and solar cells, as well as packaging materials, make certain demands of belt conveyors. With its specialized SOLTB belt conveyor range, Montech Conveyors Corp. has the ideal solution for these industries. Fuel cells are considered one of the most promising technologies for a sustainable energy future since they offer an efficient and clean way to generate electrical energy. Montech Conveyors Corp. has recently started serving these industries with its specialized belt conveyors. Their SOLTB belt conveyor range offers various solutions to support and optimize processes in fuel cell production and in production of energy and packaging technologies. Modular, flexible, and reliable…

-

Innovative solutions and world-class service

Efficient conveying and profile technology requires more than just high-quality products – it requires innovative solutions and outstanding service. Montech offers just that: With its state-of-the-art technology and a comprehensive service package, this technology company sets standards when it comes to conveying technology and customer-oriented solutions. Montech is a leading technology company that has specialized in the industrialization and standardization of state-of-the-art, unusual belt conveyors, transfer systems, and innovative aluminum framing systems for more than 60 years. Each product is manufactured to the highest industry standards to meet the demanding needs of a wide range of industries. The focus is on long-lasting, reliable, and efficient conveying and profile solutions that…

-

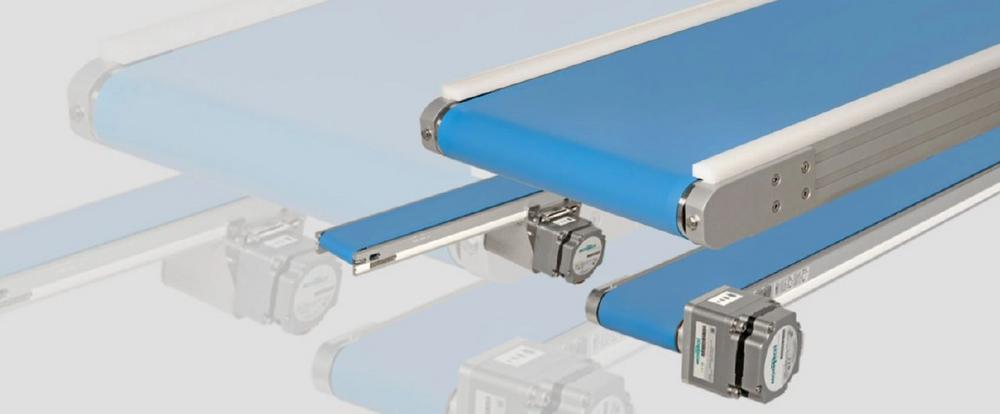

Montech AG launches a new belt conveyor line for cleanrooms

With its new belt conveyor line, this Swiss technology company now offers custom-tailored transport solutions for cleanrooms. The specially developed belt conveyors are tested and certified for cleanrooms with ISO air purity classes 4, 5, and 6. They are used in various industries such as the pharmaceutical/medical, chemical, electrical, and semiconductor industries. Cleanroom production is subject to strict cleanliness and precision requirements. Only certified belt conveyors prevent contamination by the smallest particles. The Swiss technology company Montech AG specializes in the industrialization and standardization of state-of-the-art belt conveyors, transfer systems, and innovative aluminum framing systems. Montech AG is responding to demanding cleanroom requirements with a new conveyor line in its…

-

Montech Conveyors Corp. launches a new aluminum framing system

Montech Conveyors Corp. expands its product portfolio by adding a new advanced aluminum framing system, featuring four types of profile groups and a wide-ranging line of accessories. Besides the tried and proven dovetail clamping technology, now we also offer dovetail slot connection technology and clamping technology – the disruptive geometry of the dovetail sliding nut permits precise and secure clamping. The new aluminum framing system MPS from Montech is an expansion of the successful Quick-Set aluminum system profile, which we will continue to offer. Its combination of dovetail clamping and dovetail slot connection system is unique: it enables precise and secure clamping and fastening of components and accessories to the…