-

Online training module for continuous casting now available at NSK academy

The popular NSK academy online platform now features a new training module: continuous casting. Added to the steels & metals section of the portal, the latest module will appeal to anyone involved in specifying bearings to withstand the harsh working environments found in continuous casting applications. As with all training modules available at NSK academy, registered users completing the course will require an 80% pass mark to receive a certificate. The extreme operating conditions of continuous casting machines mean that it is easy to compromise the reliability and service life of bearings without undue care and attention in the selection process. Challenges include heat, heavy loads, ultra-low speeds and roll…

-

NSK reduces machine tool quadrant glitches during circular interpolation

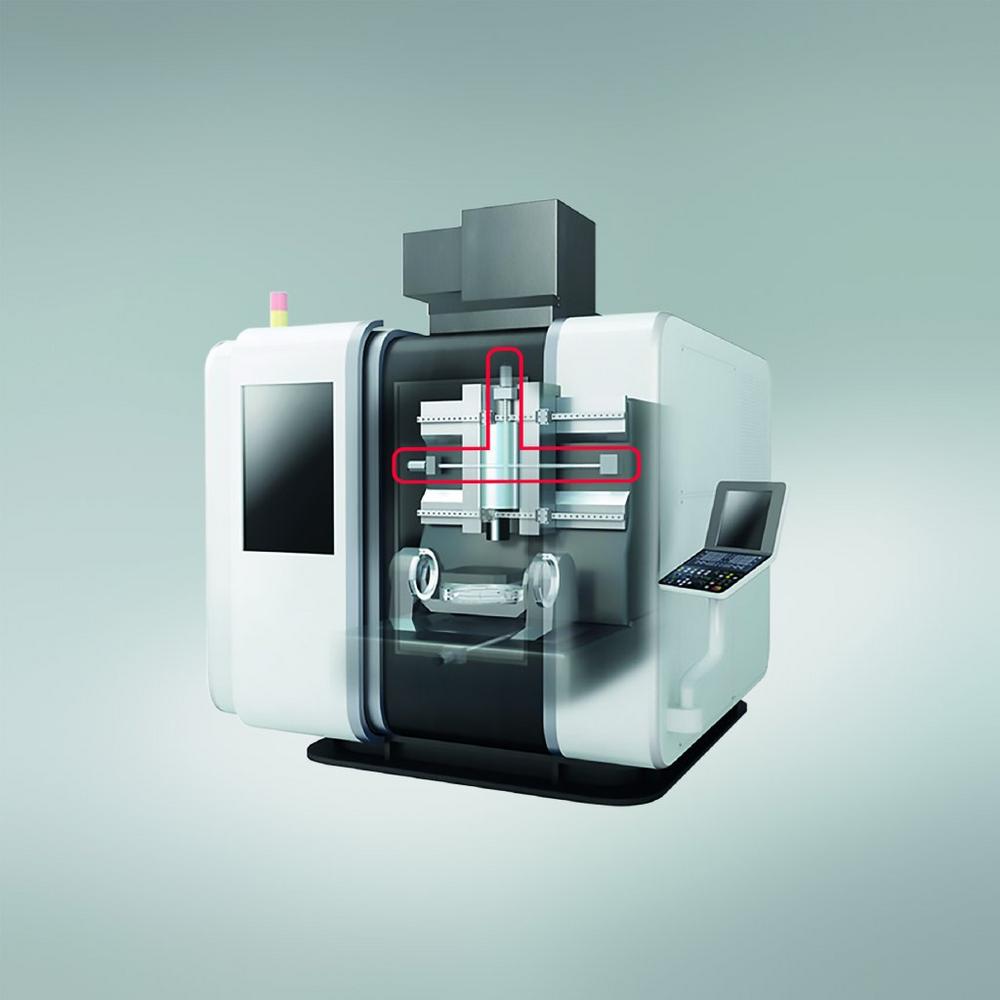

The occurrence of machine tool quadrant glitches during circular interpolation routines are an established issue. Thanks to innovation from NSK, it is possible to mitigate the effects of this unwanted phenomenon. In a world-first, new NSK technology is able to stabilise friction whenever the ball screw reverses the direction of motion, significantly reducing the propensity for quadrant glitches. Circular interpolation is a popular machining operation performed on machine tools such as CNC machining centres and milling machines, as well as EDM (electro-discharge machining) machines. Defined as motion along a circular arc, circular interpolation requires the precise coordination of two machine axes simultaneously. When performing circular interpolation, irregular friction arises when…

-

Training and professional tools extend bearing service life

A manufacturer of polystyrene-based insulating products was experiencing frequent failures in the bearings of conveyors which link its machines. However, relatively easy control of the situation arrived following a hands-on NSK training course for maintenance personnel and the adoption of the correct bearing mounting tools. To what extent does the correct mounting of bearings have an influence on their service life? In practice, this factor is often underestimated. The case of an insulation product manufacturer demonstrates that it makes sound economic sense to approach this maintenance task with the utmost professionalism. Alongside other materials, the company processes large quantities of expanded polystyrene, with 3D parts milled from sheet material. The…

-

NSK bearings with patented cage elevate performance

A new series of NSK spherical roller bearings with a patented cage design is set to provide general industry with new levels of productivity, reliability and load capacity. The optimised cage reduces internal stress and eliminates the need for a guide ring, providing just two of many benefits over existing solutions. Potential applications for the new ECA series extend from conveyors, gearboxes and steelmaking machinery, through to presses and machines used in mining. The design of NSK’s ECA range of spherical roller bearings, which supersedes the CAM series, ensures complete interchangeability with existing solutions. Notably, the nextgeneration, precision-machined solid brass cage features contoured roller pockets that significantly reduce any unnecessary…

-

Agriculture sector can boost drive-train reliability with NSK bearings

Drive-train solutions for vehicles and machines in the agriculture industry must meet a variety of performance demands that typically centre on high torque and high loads. Bearings for transmissions, differentials and prop shafts must therefore offer the highest levels of reliability and service life. NSK, based on decades of experience in supplying bearings for automotive drive trains, has successfully transferred its knowledge and experience to applications in the agriculture industry, bringing a number of distinct advantages to OEMs and end users alike. There are numerous emerging trends in the agriculture sector, which is now starting to follow the lead set by automotive. By way of example, there are growing calls…

-

Große Lasten schnell und zuverlässig bewegen: NSKLinearführungen in Werkzeugmaschinen von MCM

Seit dreißig Jahren setzt der italienische Werkzeugmaschinenbauer MCM Spa auf Antriebskomponenten und –systeme von NSK. Jüngstes Beispiel für die erfolgreiche Zusammenarbeit ist der Einsatz der NH-Linearführungen in einer neuen Baureihe von vertikalen Werkzeugwechselmagazinen und Mehrpalettensystemen. MCM – die Abkürzung steht für Machining Centers Manufacturing – startete 1978 in Piacenza/ Italien und lieferte ein Jahr später die ersten Horizontalspindel-Bearbeitungszentren mit Karussell-Palettenwechsler aus. Seit 2014 gehört das Unternehmen zur internationalen RIFA-Gruppe gehört. Kernzielbranchen von MCM sind anspruchsvolle Industriezweige wie die Automobil- und die Luftfahrtindustrie. Zu den innovativen Entwicklungen des Unternehmens gehören die Jet Five-Bearbeitungszentren, die bis zu 12 Meter lange Bauteile bearbeiten. Sie arbeiten mit Vorschubgeschwindigkeiten von bis zu 40 m/min und…

-

NSK builds on 30-year MCM partnership with new project success

Successful engineering partnerships are dependent upon many factors, not least trust, innovation, class-leading quality, technical excellence and comprehensive support. By way of example, these building blocks have provided the foundation for a strong 30-year partnership between NSK and leading machine-tool builder MCM Spa. Together, the companies have brought to market a number of innovations for the worldwide machining industry. The most recent example of successful collaboration has led MCM to adopt NSK’s NH series linear guides for use on newly developed vertical tool-change magazines and multi-pallet systems. NSK has built its success on providing customers and partners with industry-leading support, even in challenging conditions such as those presented by the…

-

New machine builds on successful IMSA-NSK partnership

The new MF1000-3T deep-hole drilling machine from IMSA is taking advantage of the benefits provided by NSK’s DIN-standard ball screws for the European machine tool market. The move builds upon a long-standing partnership between IMSA and NSK that dates back many years and involves the development of numerous machine models. IMSA intends to show the new MF100-3T at the EMO Milano machine tool exhibition in October 2021. Established in 1988, IMSA is located in Barzago, northern Italy, from where core business centres on the design and manufacture of deep-hole drilling and gun-drilling machines. As a leader in its field, there are now more than 500 such IMSA machines operational worldwide.…

-

NSK training resolves bearing failures at steel plant

Unaware that rod mill chocks had been fitted with the incorrect spacers, maintenance technicians at the plant of a steel manufacturer were facing regular bearing failures and the need to source high-cost urgent replacements. However, the intervention of NSK – via best-practice training sessions – soon resolved the issue, delivering impressive annual savings of €46,190. Maintenance technicians responsible for the rod rolling mill were oblivious to the correct way of calculating the size of spacers required for its bearing chocks. Instead, the team worked to a Standard Operating Procedure (SOP) that was 20 years old. Concerned about the costs of urgent replacements and downtime from five bearing failures a year,…

-

NSK wins two Toyota supplier awards

Toyota Motor Europe (TME) has bestowed two awards upon NSK Europe: a Certificate of Recognition (in the Supply category) and an Achievement Award (in the Quality category). In normal circumstances, TME presents the awards at its showpiece Annual Business Meeting in Brussels, Belgium, with around 200 people in attendance. This year, however, the company organised a virtual live presentation, subsequently posting the award and certificate to NSK France where the responsible EABU (European Automotive Business Unit) team for TME is located. On an annual basis, TME takes a look back at the performance of its suppliers over the previous financial year. The Certificate of Recognition in the Supply category, for…