-

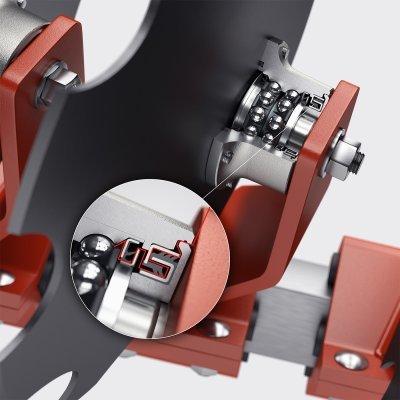

Tschudin Cube 350 centreless grinder uses NSK RA highprecision roller guides

The new Tschudin Cube 350 centreless grinding machine is using NSK’s RA series of low-friction, high-rigidity roller guides, where they are helping to generate excellent levels of surface finish on machined workpieces. Tschudin’s Cube 350 operates using the centreless cylindrical grinding method and, thanks to design innovation, benefits from the potential to install several machines side-by-side. In addition to its high-precision capability, the machine facilitates very short set-up times for product changeovers, thus enabling the economic machining of small component batch sizes. The drive design has a major impact on the performance of this precision grinding machine. Deploying linear drives in three axes (X-axis/control wheel adjustment, U-axis/grinding wheel adjustment and…

-

NSK and B&K Vibro: Expansion of CMS offering will strengthen industrial business

Effective 1 March 2021, Brüel & Kjær Vibro (B&K Vibro) became a company of NSK Ltd. On that day, the Darmstadt, Germany, headquarters of B&K Vibro staged an online welcome event to explain the purpose of the acquisition, especially to employees. In his online address, Saimon Nogami, Senior Executive Vice President of NSK Ltd., explained the goals that NSK is pursuing with the integration: "With the acquisition of B&K Vibro we expand our expertise and gain the opportunity to grow the company’s industrial business with advanced condition monitoring services. This is in line with our strategy of offering not only very high-quality motion components, but complete system solutions and services."…

-

NSK Agri Disc Hubs: Zuverlässige Wälzlagereinheiten für extreme Umgebungsbedingungen

Feuchtigkeit, Staub und Schmutz, korrosive Düngemittel und hohe mechanische Belastungen z.B. durch Steinschlag: Wälzlager in Maschinen der Landtechnik werden stark beansprucht. Exakt für diese Extrem-Anwendung hat NSK die Agri Disc Hubs entwickelt. Zu ihren Konstruktionsmerkmalen gehören ein robustes Lagerdesign und eine hochwirksame Abdichtung. Diese Lagereinheiten werden in Deutschland gefertigt. Führende Hersteller setzen sie in ihren Bearbeitungsgeräten wie Kurzscheibeneggen, Sämaschinen und Randstreifenmähern ein. Die wirklich ungünstigen Umgebungsbedingungen im Betrieb und die Reinigung der Maschinen mit dem Hochdruckreiniger stellen extreme Anforderungen an Wälzlager und Dichtungen von Bodenbearbeitungsgeräten in der Landwirtschaft. Ein konventionelles Lager weist keinesfalls die erforderliche Robustheit auf, um unter diesen Bedingungen die für einen zuverlässigen und produktiven Betrieb nötige Standfestigkeit…

-

NSK Agri Disc Hubs offer reliability in extreme conditions

For bearings deployed in the agriculture sector there is no shortage of potential hazards, including moisture, soil dust, corrosive fertilisers and very high shock loads (such as those generated by stone chipping). However, the robust bearing design and highly effective sealing of NSK Agri Disc Hubs makes them a proven choice in extreme operating conditions. Manufactured in Germany, these innovative units are a popular choice for common farming implements such as short disc harrows, seed drills and flail mowers. Extremely harsh working conditions, along with high-pressure washing routines, place a raft of demands on the bearings and seals found in equipment for the agriculture industry. A low-quality bearing will not…

-

NSK and Volkswagen cooperation delivers first success in steering innovation

In June 2019, NSK Ltd. and Volkswagen AG commenced a formal cooperation between the companies’ respective steering divisions with the ambition of further advancing innovation in steering systems. The success of this joint development initiative has led to the appointment of NSK as the production partner for a highpower, single-pinion electric power steering (EPS) system for Volkswagen’s MEB electric vehicle platform. Manufacturing will start in 2023 at an NSK plant in China, with systems supplied to Volkswagen’s electric vehicle plants worldwide. “This step represents a further milestone in the development of our steering systems,” states Thorsten Jablonski, Head of the Gearbox & Electric Drive Business Unit at Volkswagen Group Components.…

-

NSK completes acquisition of Brüel & Kjær Vibro

NSK Ltd. has completed the acquisition of Brüel & Kjær Vibro (‚B&K Vibro‘), a global condition monitoring system (CMS) specialist. Following the initial announcement on 10 December 2020, finalising the purchase of B&K Vibro from Spectris Plc. will further strengthen NSK’s ability to meet customer demand for automation, labour savings, smart technology and environmentally sustainable solutions. Condition monitoring is the process of checking a machine or system parameter, such as vibration or temperature, in order to identify a change which is indicative of a developing fault. The use of condition monitoring, which can take place while the machine is running, allows maintenance to be scheduled, or the implementation of other…

-

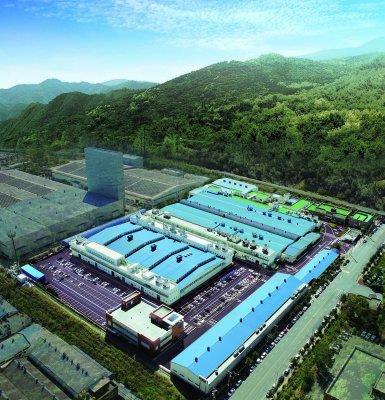

Sourcing linear motion solutions from NSK’s global manufacturing sites: the benefits of an international production network

High-precision linear guides are an important product group for NSK’s Linear Motion Technology (Seiki) management unit. As a specialist in this field, the company meets the requirements of many demanding market sectors, including the machine tool industry. Many of the linear guides supplied to European customers operating in high-precision, high-quality sectors are application-specific or adaptations of standard units. Each plant in NSK’s global production network for linear motion products focuses on specific products. The company’s NH/NS series linear guides, for instance, is among the product ranges manufactured in Changwon, Korea. Eduardo Rodriguez, Director Seiki Management Unit, European Industrial Business Unit, says: "The production of high-precision guides demands considerable know-how, which…

-

NSK roller guides simplify welding of wind turbine towers

A collaboration between NSK and Spain-based Talleres Ganomagoga has led to a major advance in the welding of wind turbine towers. Based on the latest NSK roller guide technology, innovative linear motion solutions are allowing Talleres Ganomagoga to achieve smooth and accurate movement of its welding machines as the towers increase in length during production. The Ganomagoga Group, which has history stretching back to 1974, has its headquarters in Pontevedra, in the Galicia region of northwest Spain. Initially formed to serve sectors such as marine, automotive and construction, recent years have seen a number of emerging industries come to the fore, including renewable energy and, specifically, wind power. Talleres Ganomagoga…

-

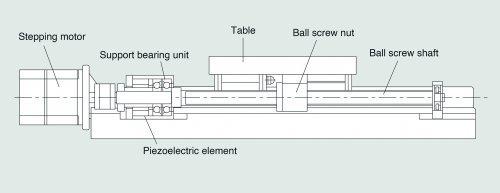

NSK shows its competency in ultra-fine positioning

As an expert in motion control, NSK frequently supplies customers with manipulators and positioners that meet micrometre and even nanometre accuracy requirements. Such solutions perform fine positioning operations under a microscope field of view, demanding the application of skilled engineering and know-how. A case in point is NSK’s nanopositioner, which exemplifies the company’s expertise in integrated mechatronics and precision positioning drive technology. This knowledge is the result of many decades spent pioneering the development of related technologies such as bearings, linear-motion products and image-processing solutions. The market demand for positioning mechanisms with nanometre accuracy continues to expand across sectors that include semiconductor manufacturing equipment, biotechnology, optical communications devices and micro…

-

New drive for Megatorque Motor boosts safety and usability

NSK has released an upgraded drive for its PS/PN series of Megatorque Motors that offers even higher levels of safety and usability. The new EDD drive unit delivers broad interchangeability and functional compatibility with the previous generation EDC drive, which has proved popular among semiconductor and electronics manufacturers for its highly reliable and accurate performance. NSK’s updated EDD also refreshes the internal electronics to secure supply chain stability of essential components. Providing the same external dimensions and supporting the existing positioning command systems, input/output signals and internal channels, the new EDD supersedes the EDC as NSK’s first choice for standard configurations. Among the key benefits of the EDD drive unit…