-

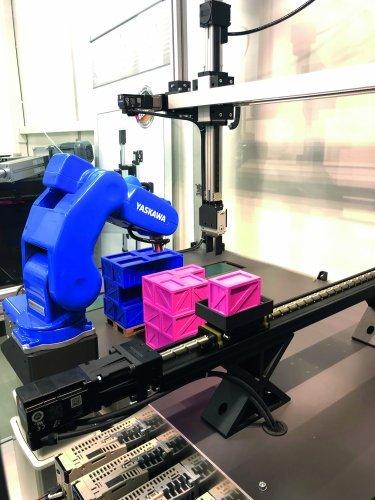

MCA demo cell features NSK Monocarrier linear actuator

An NSK distribution partner, MCA linear motion robotics, has built a state-of-the-art linear motion demonstration cell that features NSK Monocarrier technology at its core. Machine builders and system integrators tasked with creating new systems or production lines that feature automated material/product handling, can now use the MCA demonstration cell as a best practice ideas platform. MCA, the NSK authorised distributor for the Benelux region, set a project goal to create a new demonstration cell that would showcase all of its core disciplines, namely linear motion, drive technology, controls and robotics. As many of MCA’s customers build machines and/or production lines, the company decided that the theme of the demonstration cell…

-

Efficient implementation of reliable earthquake protection: using balls screws to dampen buildings and bridges

Constructing buildings and bridges in earthquake-prone regions usually necessitates the use of damping techniques. While solutions such as mass spring damping or hydraulic systems provide the traditional way of absorbing dynamic compressive and tensile forces, an alternative is to use vibration dampers featuring high-load ball screws. The use of ball screws saves space and permits easy adaptation to individual requirements. Usually deployed in industrial machinery, high-load ball screws apply a strong, uniform pressing force to servo presses and plastic injection moulding machines. For such applications, NSK has developed the broad-ranging HTF series. HTF ball screws convert rotary motion into linear motion and vice versa, offering high precision even when subject…

-

Miniature precision bearings for dental drills

In dental air turbines, miniature rolling bearings must overcome a very demanding set of challenges. As well as rotating at speeds of up to 500,000 rpm, these bearings must provide extremely quiet operation and meet rigorous hygiene requirements. NSK offers precision miniature bearings made from stainless steel especially for this application. Driven pneumatically by a turbine wheel, the two bearings in the head of the instrument ensure stable guidance of the drill during dental procedures. Miniature bearings, which have an outer diameter of just 6.35 to 7 mm, need to attain speeds of up to 500,000 rpm and stop very quickly. In addition, the bearings must avoid the generation of…

-

NSK acquires condition monitoring specialist

As part of NSK’s mid-term management plan, ‘building a CMS business’ was identified as a new mechanism for growth. Specifically, NSK plans to evolve from delivering breakdown and life expectancy diagnosis, to the provision of comprehensive technical service solutions, thus helping customers to overcome the challenges faced by equipment and machinery across a wide range of industries. Gaining access to Brüel & Kjær Vibro’s (‘B&K Vibro’) high-profile customer base, technology, brand reputation, CMS aptitude and big data, will enable NSK to accelerate its CMS business development. In addition, the acquisition will further strengthen NSK’s ability to respond to industry demands for automation, labour savings, smart technology and environmental measures. The…

-

Motorised linear actuator demonstrates NSK’s capabilities

Built upon cornerstones that include technical capability, innovation and flexibility, NSK products provide a proven pathway to competitive gain. Technical solutions only NSK can propose are contributing to the advancement of automated manufacturing at customers worldwide. A case in point is the MCE (Monocarrier Electrified), a pre-assembled, motorised linear actuator developed recently by NSK Corporation in USA. MCE showcases how technical expertise, an extensive product line-up and short delivery times can combine to improve the value of customer products. The MCE merges many product and knowledge areas from the NSK repertoire, bringing together a Monocarrier, motor, motor mount, shaft coupling and accessories. Like many solutions developed by NSK, MCE is…

-

Even more reliability with gearbox bearings for rail sector

Building on a long history of success in the rail industry, NSK has developed a new series of gearbox bearings that increases even further the reliability levels achieved by previous-generation products. The bearings, which can be used to support large and small gears in rolling stock gearboxes, are ideal for both high-speed and low-speed applications. NSK’s new bearings for small gear shafts deliver a completely new level in value through even higher reliability and reduced maintenance requirements. NSK’s bearings for large gear shafts also offer superior reliability – the standard line-up has been expanded to provide a greater range of sizes to meet diverse customer needs. Gearbox bearings are subjected…

-

Optimisation of linear guides in food production: Bakery enjoys tenfold increase in service life

When linear guides in the food and packaging industry fail to last for their expected service life, it can make sense to use solutions equipped with integrated lubrication units. These units release lubricant continuously over a long period of time. By switching to this type of linear system in its dough slicing machines, a large bakery is saving more than €200,000 a year in maintenance and downtime costs. The linear guides serving the process-integrated band cutters in the bakery’s dough slicing systems were failing every three weeks on average. Despite being coated with an Armoloy finish – and using food-grade grease – the desired performance criteria could not be met.…

-

NSK bearings offer 4.5 times more life on bakery oven fan

A leading UK bakery was experiencing regular, unexpected stoppages due to the premature failure of pillow-block ball-bearing mounted units fitted to the recirculation fan of a high-temperature oven. However, switching to NSK plummer blocks with high-capacity spherical roller bearings and labyrinth seals increased service life by a factor of 4.5, delivering annual cost savings of €34,907. Failures of the pillow-block mounted bearing units were causing significant disruption to the bun production line at the bakery, leading to high downtime costs and spoilt product. With bearing failures occurring every 6 weeks, the management team invited NSK’s team of experts to investigate the issue as part of its AIP Added Value Programme.…

-

Bearings for rolling mills: new online training module added to NSK academy

A new training module for rolling mills has been introduced to the NSK academy online learning platform (www.nskacademy.com). The latest module is targeted at those involved in specifying or maintaining bearings that need to withstand the challenging working conditions found in rolling mill applications. Like all training modules available at NSK academy, registered users attaining an 80% pass mark will receive a certificate denoting their achievement. The nature of processes such as steelmaking and ironmaking mean that heat, contamination, heavy loads, vibration and impact are just some of the issues facing bearings required for use in rolling mills. NSK’s latest online training module aims to explain how the effects of…

-

NSK linear guides prove ideal for face mask machines

When a UK specialist in automation and machine building was asked to manufacture face mask machinery in urgent response to the COVID-19 pandemic, it turned to the proactive team at NSK and the company’s long-life NH series linear guides. Family-owned Sims Engineering (simsengineering.com) was established in 1982 to specialise in the design and manufacture of automated systems and special purpose machinery. Much of the work performed by this ISO9001-accredited business is destined for customers in the automotive, pharmaceutical and food sectors. However, when the COVID-19 pandemic arrived, the company responded immediately to a request for automated face mask manufacturing machines. Sims Engineering is known for its ability to produce machines…