-

New white paper outlines value of proven aftermarket parts suppliers

NSK, a global supplier of motion and control solutions for industrial markets, has created a new white paper about the added value that can be provided by partnering with a proven specialist in aftermarket parts. This insightful and free-to-download white paper sets out the benefits of developing a strong supplier relationship, the competitive advantages it brings and the pathway to machine optimisation. Although aftermarket items such as bearings, lubricants, tubing and couplings have historically been warehoused as expendable commodities, the smart, lean manufacturers of today are increasingly aware that any machine or system is only as successful as its weakest component. A sub-standard bearing, for example, can therefore prove extremely…

-

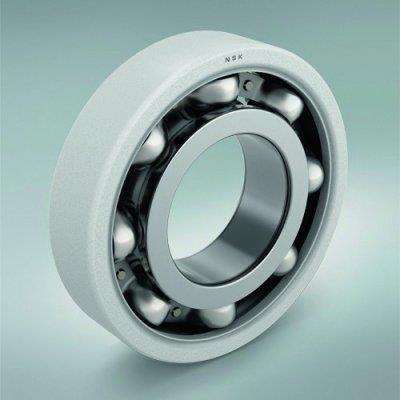

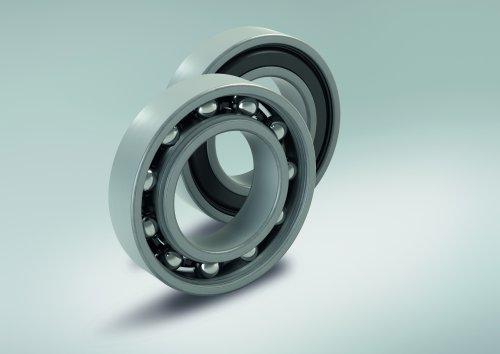

NSK bearings with ceramic coating benefit VSD users

NSK has developed a series of deep groove ball bearings featuring an optimised ceramic coating that benefits users of variable speed drives (VSDs) and electric motors. The insulating effect of the coating prevents current transfer, which not only extends bearing service life but avoids damage to adjacent drive components. Energy-efficient VSDs are becoming increasingly popular in a host of industrial machines, systems and equipment. The use of VSDs is particularly economical when different power levels are required in response to variable demand. However, frequency regulation calls for bearings that fit a different set of requirements, largely because there is always the risk of parasitic current reaching the driven components via…

-

NSK initiatives combat counterfeit bearing manufacture

As a respected and coveted manufacturer of premium bearings, NSK has long been the victim of unscrupulous counterfeiters. Looking to cheat both the OEM and the user, those producing fake bearings will stop at little to deceive purchasers and boost the profitability of their illegal operations. However, NSK is fighting back with a range of measures that aims to nullify this corrupt practice. To highlight the extent of the problem, around 23,000 counterfeit NSK packages and labels were recently discovered in Hebei Province, China, while a follow-up raid at another factory owned by the same offender revealed over 90,000 counterfeit bearing boxes and 10 imitation printing plates covering four major…

-

New-generation bullet train relies on NSK bearings

High-performance bearings from NSK are now operational in the newly developed N700S Shinkansen (bullet train), which from 1 July 2020 began service on the Tokaido Shinkansen line between Tokyo and Osaka. The N700S marks the start of a new era, being the first completely new Shinkansen design from the Central Japan Railway Company in 13 years. NSK bearings underpin the train’s no-compromise focus on safety, stability, comfort and environmental performance. Bearings for railway applications contribute directly to safe operation and travel. High reliability is key, as is the ability to support elevated speeds, improved energy efficiency and reduced maintenance requirements. The demands placed on railway bearings are especially apparent in…

-

Extended service life with NSK NH/NS linear guides

The number of machine builders and end users benefiting from the NH/NS series of linear guides from NSK is continuously expanding in new fields and applications, thanks largely to a long service life which is double that of conventional products. This longevity is a primary advantage in an industrial landscape where minimising TCO (total cost of ownership) is vital. Maintenance requirements are reduced considerably when using NH/NS linear guides, as is the risk of expensive machine downtime due to premature failures. The reason that NH/NS linear guides offer greater service life results from the inclusion of innovative features like specially developed ball groove geometry. In addition, up to 30% more…

-

NSK unveils new bearings catalogue for electric motors

NSK has published a new catalogue that showcases its extensive range of standard bearings for electric motors. As well as focusing on solutions such as deep groove ball bearings and cylindrical roller bearings, the 36-page catalogue contains a wealth of advice and technical information for any engineers involved in electric motor design or maintenance. he catalogue’s easy-to-read format sees bearing requirements set out for electric motors in four principal application areas: servomotors, high-efficiency motors, speed-controlled (inverter) motors and electric vehicle (EV) motors. For each area, the optimum bearing range is presented together with key design characteristics and accompanying technical information. This applies to both the company’s standard series and NSKHPS…

-

How to identify and avoid buying fake NSK bearings

When a company´s reputation is at stake, no purchasing or engineering teams want to fall into the trap of purchasing fake bearings. Every year, NSK invests heavily in identifying and prosecuting counterfeiters, but knows that the best way to stop these bogus operations is to halt demand. With this thought in mind, informing customers of ways to identify and avoid buying replica bearings is hugely beneficial for all stakeholders. Most end users that receive counterfeit bearings believe they have purchased genuine products and, lacking expertise in this technology, will find it almost impossible to tell the difference between real and fake items at the point of delivery. As a result,…

-

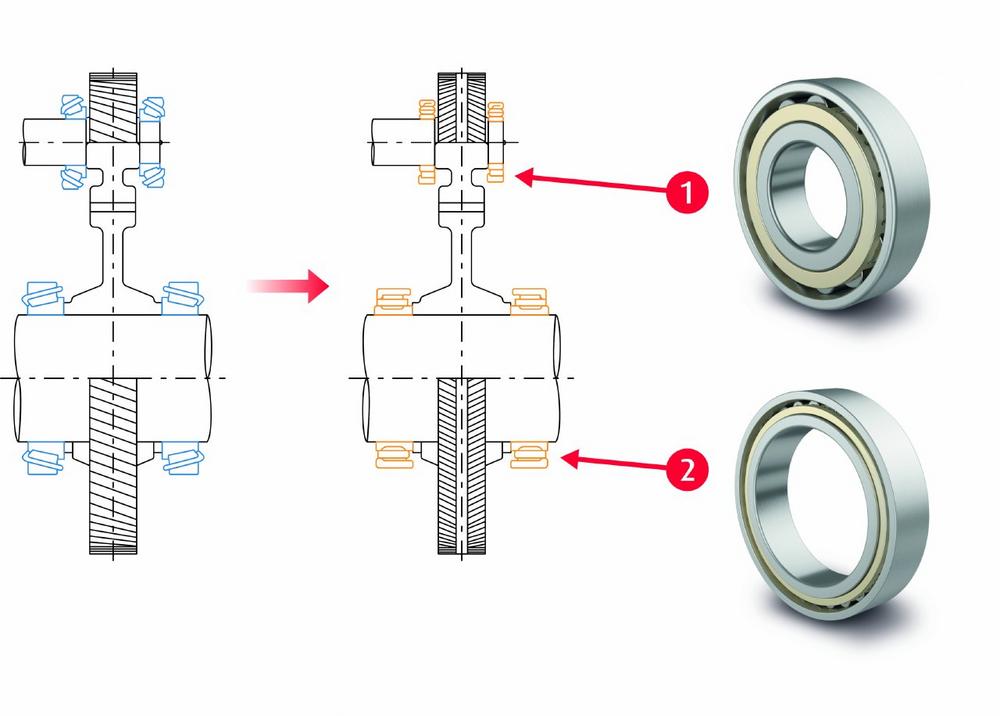

NSK bearings adapted to meet servomotor demands

Available from NSK is a range of deep groove ball bearings adapted to the specific requirements of servomotors. Thanks to the development of special greases and a highly effective, low-friction seal, NSK solutions overcome the limitations of conventional electric motor bearings when used in servomotor applications. For rolling bearings, servomotors present a challenge. With their frequent start, stop and reversing operations – as well as tiny corrective movements prompted by the sensor system – the typical motion profile of servomotors places bearings under intense stress. Furthermore, the frequent reversing and associated micro-vibration cause the lubricant film between the rolling element and running surface to be wiped away (without the opportunity…

-

NSK adds manufacturing technology to its core focus areas

For many years NSK has focused its development competence on the company´s four core technologies of tribology, simulation/analysis, mechatronics and materials engineering. Now, these core areas are being joined by a fifth: manufacturing technology. The move to ´four core technologies plus one´, highlights the increasing importance of optimised machines, systems and equipment in the manufacture of high-quality bearings. Moreover, through this addition NSK is acknowledging the growing influence of global trends such as the IoT, Industry 4.0 and artificial intelligence (AI). When NSK develops new generations of bearings, the key objectives that the company seeks to attain include higher speeds, lower friction, improved energy efficiency and prolonged service life, even under…

-

NSK develops ultra-high-speed ball bearings for EV motors

NSK has developed a new ball bearing that, thanks to its ultra-high-speed capability, is ideal for use in the traction motors of electric and hybrid vehicles. As well as allowing electric motors to operate at higher speeds, the new bearing improves fuel economy (reduced power consumption per unit distance), supports the increase of vehicle range and contributes to better user comfort. To enhance global sustainability, the automotive industry is rapidly expanding the development and production of electric and hybrid vehicles. However, the maximum achievable range on a single charge remains a concern for consumers. As a result, automakers are pursuing smaller and lighter components, and developing faster, higher output motors.…