-

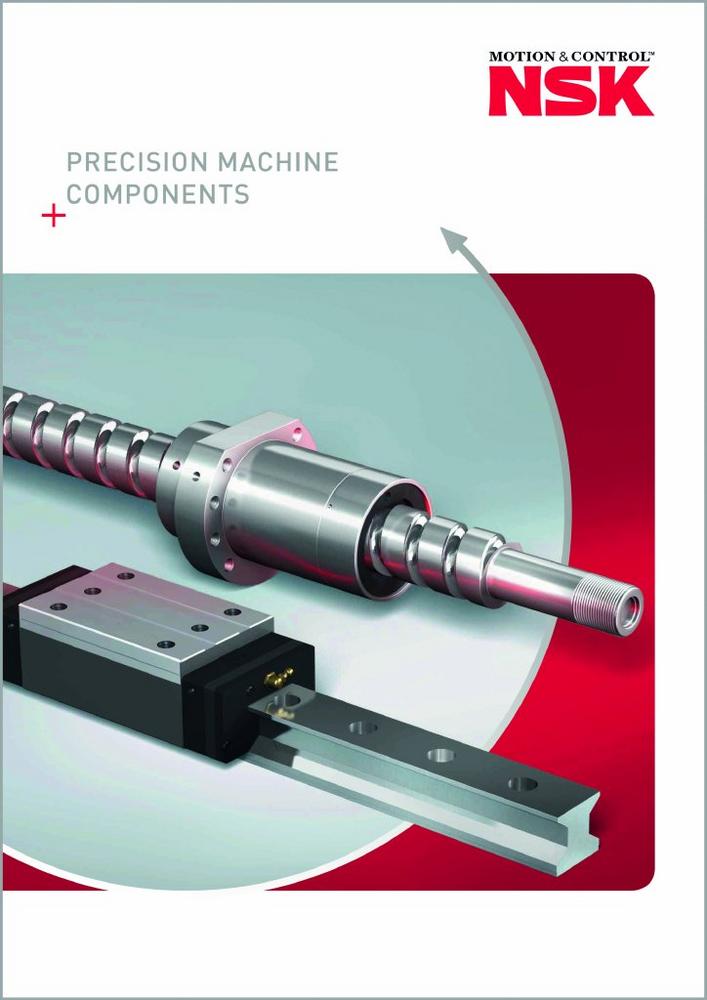

New Precision Machine Components catalogue from NSK

By releasing a new edition of its Precision Machine Components catalogue, NSK is providing existing and potential customers with an up-to-date overview of its comprehensive linear guide, ball screw and monocarrier portfolio. At more than 700 pages in length, the publication also acts as a manufacturer-neutral guide to selecting and calculating the service life of linear components for machine or equipment-building applications. By way of example, 60 pages are dedicated to providing manufacturer-neutral information on the selection of ball screws. These pages complement the presentation of NSK’s range of ball-screw solutions, which covers a further 400 pages. The chapters on linear guides extend over 300 pages and contain detailed…

-

New NSK heat treatment plant protects supply chains

NSK customers around the world, including those in Europe, are set to benefit from the construction of a new heat treatment facility in Japan. The move comes as part of a continuous effort to strengthen the structural resilience of the NSK Group, while simultaneously providing a productivity and efficiency boost. Following the completion of the ¥3 billion (approximately €23.78 million) heat treatment plant at NSK Toyama, the company has transferred a percentage of heat treatment processes from NSK Fujisawa to the new 3,641m2 facility. This business continuity planning (BCP) measure has been implemented to help protect supply chains in the event of a natural disaster such as an earthquake or flood.…

-

Recycling plant saves over €50,000 per year with NSK mounted bearings

A recycling plant that was experiencing regular failures of mounted bearings on the conveyor of an optical sorting machine is enjoying major gains following the switch to NSK SNN series plummer blocks fitted with NSKHPS spherical roller bearings. Thanks to the reduction in replacement bearing costs, breakdowns and maintenance, the facility is saving €51,174 per annum. The problem at the recycling plant came to light soon after installation. Within just three months, five bearing failures had been recorded. Keen to resolve the issue, which was proving expensive in repairs and downtime, the facility´s management team invited NSK to perform a comprehensive application review. As part of its AIP Added Value…

-

NSK Verify app upgraded to include industrial bearings

The NSK Verify mobile app has been upgraded to include the company’s range of general, giant and extra-giant bearings for industrial applications. When first launched, the NSK Verify bearing authentication app initially focused on the company’s super precision bearings, which are designed for use in machine tools. Extending the free app to further product lines will bring more efficient operations and IT-based plant management to wider industry. NSK Verify provides product authenticity information by reading the 2D barcode printed on each bearing box and checking it against the NSK database. Factors such as authenticity and traceability are vital in an era when fake bearings remain prevalent, despite a considerable amount…

-

Tips for replacing wheel hub bearings

When it comes to vehicle repairs, NSK sets out to make processes faster, safer and more reliable for garage technicians and mechanics. For this reason, those purchasing NSK ProKIT solutions receive 100% genuine wheel bearings alongside all of the supporting components needed to perform a fast and high-quality wheel bearing replacement. Hub bearings are not the simplest of parts to install, which is why NSK is providing some extra tips to help avoid common mistakes. The first tip is to compare the fitted bearing to the new one before mounting. Selecting the incorrect bearing is the most common mistake made by technicians. If the bearing is selected correctly, it can…

-

NSK TL bearings double service life in papermaking machinery

NSK spherical roller bearings with TL technology are being increasingly adopted in the papermaking industry as more machinery manufacturers and paper mills seek to maximise operating life and uptime. The unique attributes of NSK’s TL (tough and long life) specification is proven to provide greater resistance to hoop stress, subsequently reducing inner ring fractures and delivering service life more than twice that of conventional bearings with standard heat treatment. TL series spherical roller bearings are specifically designed for sections of papermaking machinery where elevated temperatures prevail, including dryer rolls, calender rolls, canvas rolls and PV rolls. The bearings were developed as a solution to a specific problem: inner ring fractures.…

-

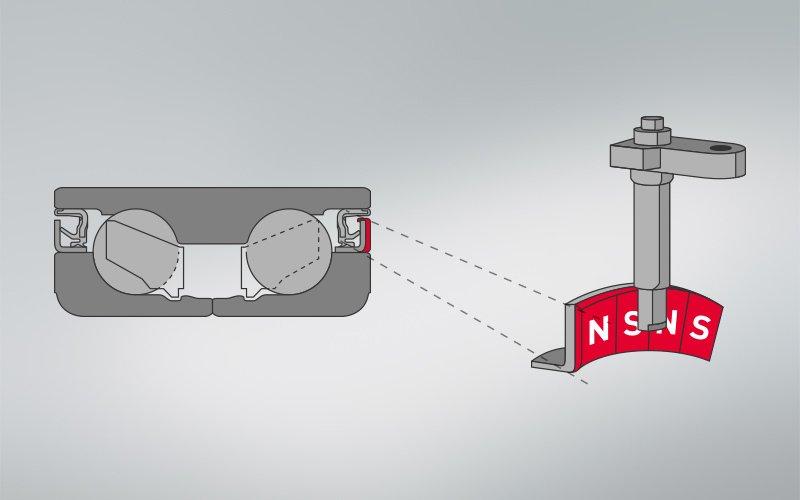

Counterfeit bearings – know the risks

Counterfeit bearings are a global issue, with all markets susceptible to the risks of buying these low-quality products. As a leading manufacturer of premium-quality bearings, NSK is focused on eradicating this issue, one that puts safety at risk and ultimately leads to users experiencing reduced reliability and higher lifecycle costs. The relentless drive to remain competitive and profitable has created a culture where too many companies are forced into making purchase decisions based solely on unit price, ignoring other factors such as total cost of ownership (TCO) and performance. However, shopping around for irresistible bargains often comes at a far higher price, with many purchasing and engineering teams unaware of…

-

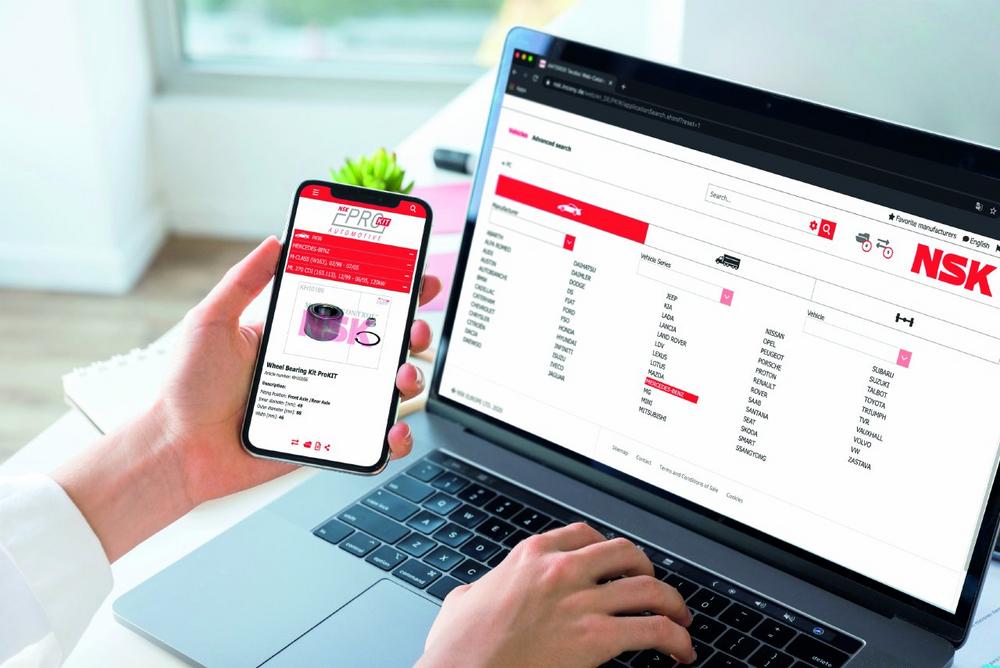

New online catalogue for NSK automotive aftermarket parts

NSK has launched an online product catalogue that spans the portfolio of its wheel bearing kits for the automotive aftermarket (AAM). Placing the entire range of NSK ProKIT solutions at the fingertips of distributors, wholesalers and garages means that browsing and selecting the correct wheel bearing kit could not be easier. ProKIT packages for the AAM contain only 100% genuine wheel bearings, as tested and approved by the OEM. Moreover, ProKIT comprises all components necessary to mount the product concerned, including snap rings, seals and fasteners. The new NSK online catalogue features a comprehensive collection of ProKIT solutions, which are grouped by OE reference for passenger cars, commercial vehicles and axle…

-

NSK pledges open IP access for COVID-19 activities

NSK, one of the world’s leading manufacturers of bearings, linear motion technologies and steering systems, has signed up to the new ‘Open COVID-19 Declaration’, signalling its commitment to a global effort that is seeking a swift end to the spread of coronavirus disease 2019 (COVID-19). Through this unprecedented declaration, NSK is pledging to make its intellectual property (IP) freely available for development, manufacturing and other activities central to stopping transmission of the virus. Preventing the advance of COVID-19 requires the rapid development, production and distribution of therapeutic drugs, vaccines, medical devices and infection prevention products. The Open COVID-19 Declaration calls on IP owners to make their patents, utility models, design…

-

NSK saves nearly €3 million at steel mill

A steelmaker based in Poland is saving nearly €3 million per year after switching to NSK’s sealed-clean KVS bearings in its roll mill. Such has been the superior performance of these four-row tapered roller bearings that the company has adopted this solution for all of its tandem cold mills. The steel mill in Poland started production in the 1970s. After many years of operation, the management team decided that a refurbishment was necessary. To help reduce costs, the mill consulted with a local technical university on the potential for changing the roll mill bearings from oil mist to oil bath lubrication. Oil mist lubrication was seen as problematic, but switching…