-

Game changer for green hydrogen: SensoTech’s unbeatable measurement technology

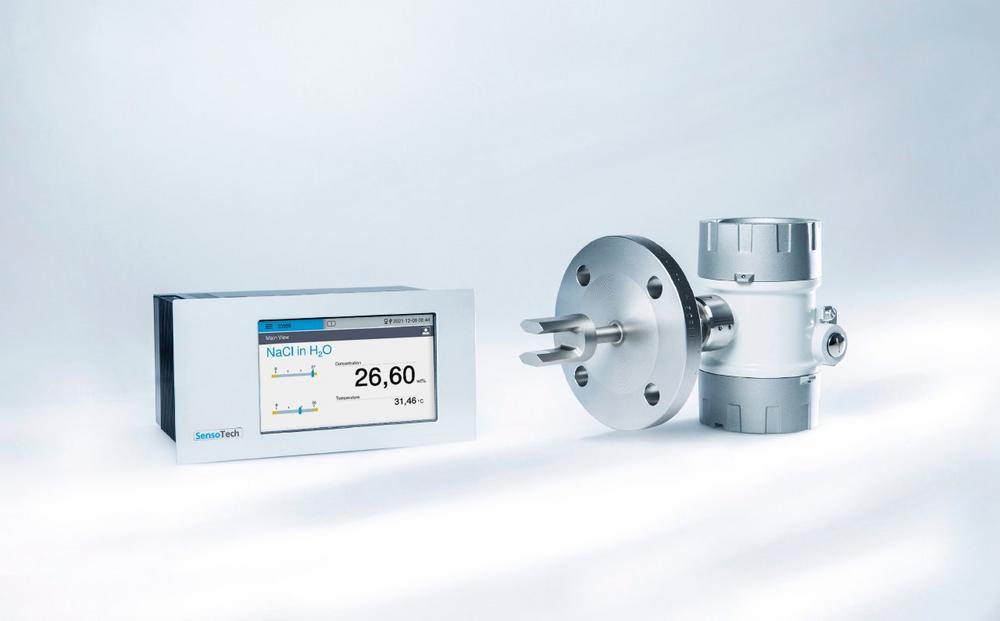

. Precision meets innovation: SensoTech is shaping the future of process analysis SensoTech is setting new standards in the world of industrial fluid analysis. With high-precision measurement technology and innovative sensors, the company is revolutionizing process monitoring and offering pioneering solutions for various industries. LiquiSonic® – The future of inline analysis SensoTech’s LiquiSonic® technology is based on the measurement of the sonic velocity using ultrasound and enables the exact determination of concentration and density in liquids. The precise inline monitoring provides real-time data that enables companies to adjust their processes immediately – for maximum efficiency and quality assurance. Whether concentration and density measurements, phase detection or the analysis of complex…

-

Innovative Inline Monitoring in Sulfuric Acid: Impact on Safety and Efficiency

SensoTech presents the latest webinar series on the impact of innovative inline monitoring on safety and efficiency in the production and application of sulfuric acid. From November 14 to 16, industry experts and leaders will provide deep insights into the latest technologies and solutions specifically designed to meet the highest industry standards. The sulfuric acid market faces unique challenges, especially when it comes to safety and efficiency. SensoTech, with its proven LiquiSonic measuring systems, meets these requirements by providing solutions that enable highly precise measurements in real-time, even under the most demanding production conditions. These are optimally suited for the specific and steadily growing requirements in the sulfuric acid industry.…

-

Improved plant safety and higher product yield thanks to LiquiSonic®

Phase separation is a fundamental process in various industries where a product passes into two or more separate phases, each of which has different physical or chemical properties. A fast and reliable differentiation of these phases is crucial for the efficiency and safety of chemical, biotechnological and industrial processes. Failure to detect the differences between the phases in time can cause massive problems for production processes and the associated companies. It is therefore important that the latest and best technology is always used in industrial processes to minimise these risks and ensure quality and safety. Advantages of the LiquiSonic® measuring system The inline measuring system LiquiSonic® enables the detection of differences…

-

Monitoring of chlor-alkali electrolysis sub-processes

Chlorine and caustic soda are essential chemicals whose production is indispensable for downstream chemical processes. Due to the immense production volumes, small deviations and errors in the individual production steps can mean large financial losses. For this reason, complete and accurate process monitoring is important. With LiquiSonic® SensoTech GmbH offers a process monitoring system that meets these high requirements. Monitoring of reactant and product quality Precise monitoring of the starting materials already shows its advantages during the preparation of the brine. With LiquiSonic®, the concentration of the sodium chloride solution can be precisely adjusted down to 0.1 m%. Maximum saturation prolongs the life of the membranes during electrolysis and saves…

-

Also for potentially explosive areas: LiquiSonic® OCR for the determination of the oil content in refrigerants

Determining the oil content in the refrigerant circuit often brings challenges for users. Sampling is difficult due to the high pressure in the circuit. In addition, the refrigerant evaporates as soon as it is removed from the circuit. In some cases, this is compounded by the fact that flammable gases, such as propane (R290), are used as refrigerants. Of course, this goes hand in hand with special requirements for the measuring systems. Particularly in large-volume test stands, which are often located in research and development centers, a special degree of protection is therefore required. Unbeatably simple and at the same time very precise SensoTech has the solution for these cases:…

-

Smart monitoring of oil concentration in the refrigerant circuit

Decades of experience show that measurements, especially in the refrigerant circuit, are costly and complicated in research as well as in test centers. Sampling is often difficult or not feasible. Therefore, in practice, the ratio between oil and refrigerant is often estimated by indirect methods. In order to perform these measurements as precisely as possible, SensoTech has developed the inline solution LiquiSonic® OCR, which offers unbeatable advantages. SensoTech places the highest value on precisely measured values when monitoring oil concentration. The determination of the oil concentration is based on pressure, temperature and sonic velocity measurements in the liquid refrigerant. This measuring principle enables highly accurate and fast adjustment of the…

-

Innovative monitoring of gas scrubbers by means of sonic velocity

Environmentally harmful, corrosive or toxic gases are used in a large number of industrial processes. To protect people and the environment, the treatment of these gases is subject to strict regulations, in particular which purification criteria a gas scrubber must achieve. Ensuring the complete conversion of toxic components while using scrubbing liquid efficiently is often a challenge for process engineers. The effectiveness of a gas scrubber depends on the exact dosage of the scrubbing liquid (for example: caustic soda). To enable an exact determination of the concentration of the scrubbing liquid and the salts, two physical measurands have to be combined. Conventional measuring methods often map only one measurand and…

-

Monitoring of the concentration of sulfuric acid and oleum by means of sonic velocity

Conventional monitoring of sulfuric acid and oleum is carried out in many production facilities with manual sampling. These samples are then analyzed in the laboratory and a result is available a few hours later. In production, fast and accurate monitoring of the concentration is of great importance, as this influences the quality. It is precisely this determination of the concentration that can be ideally realized by means of sonic velocity with very high measuring accuracy. It is a challenge for many users that although sulfuric acid and oleum occur in the same part of the plant, identification with a physical quantity alone is not possible. Therefore, empirical values have to…