-

Toray Announces Breakthrough Photosensitive Polyimide Delivering Exceptional Precision and Sustainability for Next-Gen Electronics

Toray Industries, Inc., announced today that it has developed the STF-2000, a photosensitive polyimide solution that enables high-aspect-ratio fine patterning with 30-micrometer line widths in films up to 200 micrometers thick. This breakthrough came from applying advanced high-sensitivity negative-tone formulation and proprietary photoresist design technology, which controls curing stress (see Figure 1). This new material retains the inherent advantages of a polyimide structure. These include excellent resistance to heat and chemicals, mechanical strength, insulation, and X-ray durability. At the same time, it enables fine microfabrication with aspect ratios of up to 7. Sustainability also informed the STF-2000’s engineering. It is free of N-Methyl-2-pyrrolidone (NMP; see glossary note 1) and per-…

-

Toray Develops High-Precision Hollow Fiber Membrane Module with Nano-Structural Control that Can Streamline Food Production and Reduce Carbon Dioxide Emissions and Costs

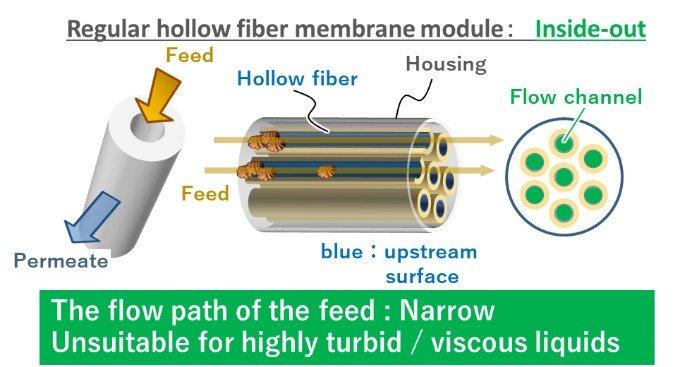

Toray Industries, Inc., announced today that it has developed a high-precision hollow fiber membrane module for food and beverage production and biorelated applications. The new offering employs the company’s nano-pore structural control technology. It retains the high heat resistance and permeability needed for these applications with its pore size, or molecular weight cut-off (see note 1), reduced to around one-quarter that of Toray’s conventional counterparts. This enhances recovery rates and concentration ratios for proteins and polysaccharides with a broader range of molecular weights to streamline processes. Additionally, this technology also helps reduce carbon dioxide emissions and manufacturing costs. Toray has started shipping samples to customers. The company has drawn on…

-

Toray Creates Stretchable Film with High Dielectric Constant and Resilience that Helps Cut Actuator and Sensor Weight and Energy Consumption

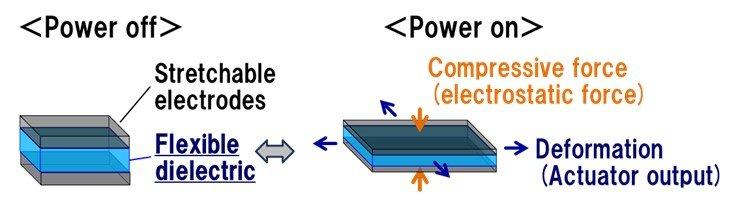

Toray Industries, Inc., announced today that it has augmented its REACTIS® brand of high-recovery film technology by innovating a stretchable c film with a high dielectric constant and recoverability. Applications should include dielectric components in dielectric elastomer actuators (DEAs) for robots, sensors for reducing weight and saving energy, flexible sensors suitable for curved 3D curved surfaces, and energy harvesters. Toray will set up a sample distribution system for users and strive to swiftly commercialize this breakthrough. Recent years have seen attention focus on soft robots to interact with people in such fields as healthcare, eldercare, and food production. Conventional robots require many sensors and complex controls. In contrast, “soft” robots comprising compliant…

-

Core Shell 3D Molding für höhere Festigkeit

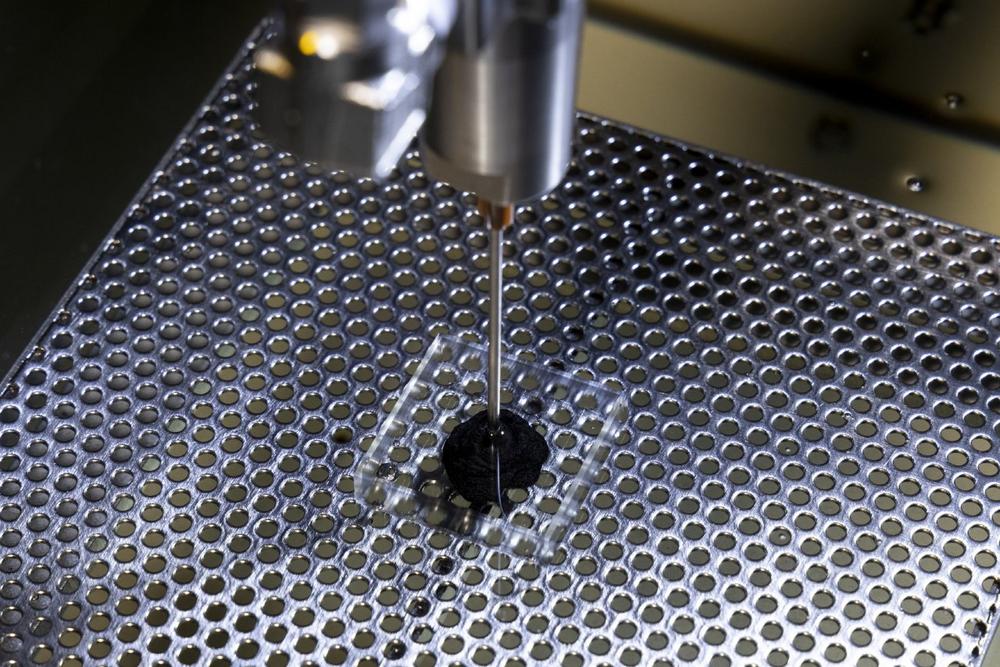

Toray Engineering Co., Ltd hat auf der „JEC World 2024“ in Paris eine 3D-Formmaschine für Carbonfaserverbundmaterial vorgestellt. Die Maschine verwendet die innovative Core-Shell-Methode. Objekte, die mit 3D-Druckern hergestellt werden, weisen eine Anisotropie in Bezug auf Festigkeit und Steifigkeit auf. Der Grund dafür ist, dass die Maschinen Harz- und Metallmaterialien in vertikaler Richtung schichten. Die mechanische Stabilität ist dadurch in vertikaler Richtung geringer als in horizontaler. Die von Toray Engineering entwickelte „Core Shell CF Composite Material 3D Molding Machine” verfolgt einen neuen Ansatz. Bei der „Kernschalenmethode“ erzeugt ein lichthärtender 3D-Drucker schrittweise eine Schale, die als Form dient und fortlaufend mit dem duroplastischen CF-Verbundmaterial ausgegossen wird. Im Anschluss wird das flüssige CF-Verbundmaterial…